According to Retail Wire, overstocks and out-of-stocks cost companies over $1.1T globally in lost revenue. In this article, we take a close look at what tech trends can level up your inventory management game, what you need to develop or scale your inventory management system, and the success stories of industry leaders. Let's:

- Take a look at the market analysis;

- Discuss 5 trends that empower any inventory management software;

- Learn about major stages of inventory management software development;

- Find out how to choose the best partner for successful implementation.

What is inventory management software?

It's a system that tracks and manages current stock, including how the items get in, move around, and out of business. If the software works properly, it helps companies to ensure they have the right amount of inventory, at the right time, and in the correct location. A complex system allows you to control the stock, monitor its movement, and replenish it when needed.

Inventory management software: market overview

The inventory management software market exceeded $3B in 2019, and it is expected to grow up to $5B by 2026. North America accounts for 40% of the market, but the Asia-Pacific region is trying to catch up and reach 25% of the market share by 2026.

Inventory management software market is projected to grow significantly. The 2020 growth of e-commerce and its turnover increased the need for a well-developed inventory management system. Some companies opt for the out-of-the-box model and choose one of several solutions available on the market. At the same time, others understand the need to develop custom solutions that will meet their expectations and work seamlessly with other systems.

But how can make the most out of your inventory management system?

5 tech trends that will bring your inventory management software to the next level

In this section, we will take a look at five technologies and solutions that are changing the traditional approach to inventory management software development. We will also share our experience in implementing these tech solutions for our clients.

-

Using mobile solutions

Enterprise mobility has been a subject of heated discussions for quite some time. APAC and European markets are market leaders in the adoption of mobile solutions [1]. However, it rarely covers inventory management. Let's take a look at some of the doors that this technology opens:

By introducing mobility into inventory management, the company can:

- Get enhanced visibility into all the processes on different levels

- Manage inventory in real-time.

- Reduce the time needed for physical inventories and cycle counts.

- Easily monitor maintenance procedures.

Fluke Corporation is the world leader in the manufacturing, distribution, and servicing of electronic test tools and software. The client needed to get better visibility into the asset condition and ensure high performance, customization, and scalability of multiple services.

What has been done?

The N-iX team has been working on Fluke Mobile, a solution that enables users to perform work order management and inventory management tasks from mobile devices. The N-iX team developed a brand new enterprise mobile system using Java and hybrid mobile technologies. The system is cross-platform, and it supports both cloud and on-premises deployments. Mobile application runs on iOS, Android, and Windows Mobile. One of the key features is the offline support mode that allows for complex business features on mobile devices. It stores events into the device's DB and syncs back via message queue when the application is up and network connection reestablished.

What we achieved together?

- We have developed a highly portable software that is deployable to all major operating systems on customer premises and clouds.

- A mobile client supports all major mobile platforms with native features. It can also accommodate up to 90% of software updates without the need to reinstall the app.

- All the mobile solutions are interoperating with various PLC/SCADA and CMMS systems.

- Enterprise mobile and integration products are developed following high standards of security, reliability, scalability, and extensibility.

-

Wider adoption of data analytics

Modern enterprises collect tons of data. However, nearly half of that data typically goes unused as the companies have little to no idea on how to utilise it. The 2020 research shows that smaller companies are more efficient with their data use, compared to larger ones.

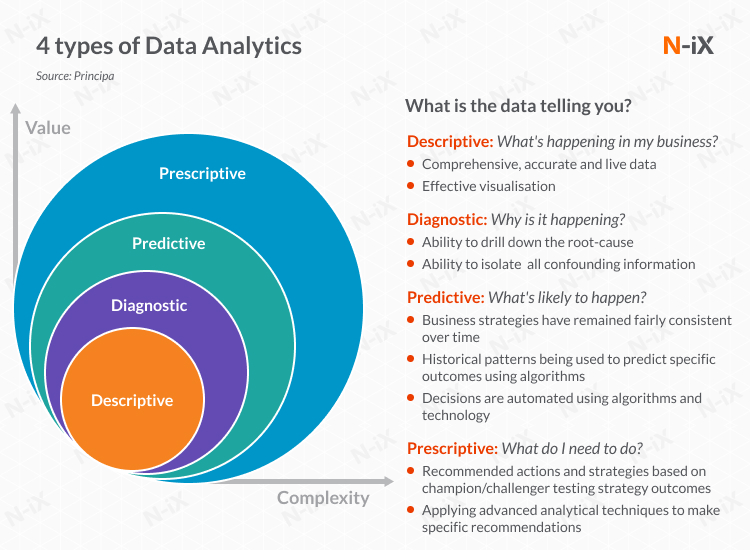

Inventory management relies heavily on data analytics. There are four major types of data:

- Descriptive. It helps you understand what is happening with your inventory. It can also show you whether your processes are effective.

- Diagnostic. This type of analytics enables you to dig up the root cause of the failures in your processes. It also allows you to isolate invalid or confusing data to be analyzed separately.

- Predictive. Predictive analytics helps companies understand the tendencies in demand and plan their activities accordingly. With the help of algorithms, it also allows businesses to anticipate certain market changes.

- Prescriptive. This form of analytics accounts for complex evaluation of the processes and allows to make specific recommendations to improve certain strategies or approaches.

The sooner companies understand the true value of data, the easier it will be for them to gain the most competitive advantage from it. Adopting data analytics can help them improve their processes, liquidate the excess stock, improve their approach to inventory classification, forecast the demand more effectively, and much more.

Our client, a Fortune 500 industrial supply company, needed to efficiently manage large amounts of data, including the data on inventory-related costs. With over 1.6M in-stock products and more than 3 million customers in North America, the company wanted to extend its data warehouse solution, collecting data from multiple departments.

What has been done?

Before suggesting any technical solutions, our experts have thoroughly analyzed the client's business needs. We have created a proof of concept to choose the most suitable data warehouse design and the tech stack. The chosen solution was built with Snowflake data warehouse solution, as it met the client's approach of cloud neutrality: it can easily scale up and down for any number of workloads or computing power, regardless of the cloud(s) that are in use.

Another task was to migrate from the on-premise Hadoop Hortonworks cluster to AWS and process additional data in AWS. So, we have built an AWS-based big data platform from scratch. We have also been involved in extending and supporting the existing Teradata solution.

We focused on the cloud-agnostic approach and made sure that the client can easily change the cloud provider and choose the one with the best offering.

What we achieved together?

The cooperation is ongoing. Our experts have built the environment to enable processing large datasets. The chosen tech stack allows us to automate the data extraction process. We have integrated more than 100 different data sources into a unified data platform. This includes daily data loads, along with a backfill of historical data. All these steps allowed us to bring the maximum value to our client:

- Reduced infrastructure costs due to the cloud migration.

- Improved efficiency of data management.

- Predictive analytics capabilities of the platform.

- Using a cloud-neutral approach that allows avoiding vendor lock-in and unlocks benefits from different cloud providers.

Read more: Big Data in manufacturing: How to make the most of it?

-

Deeper integration of machine learning and AI

Machine learning and artificial intelligence can be highly beneficial for inventory management. They can help companies understand the tendencies, optimize their processes, gather insights, and make informed decisions. Here are some of the benefits of introducing ML algorithms while developing inventory management software.

Here are some of the things you can do to gain maximum value from your ML and artificial intelligence in inventory management.

- Evaluate your resources. While deliberating whether to add ML, you need to evaluate the technology and development team you already have carefully. This type of development is not fast and requires dedicated data sources, computing power, and a development team.

- Prepare your data. ML models require a lot of data. Lack of proper data is one of the key concerns in AI development. All the data should be clean and well-processed. Up to 80% of efforts typically goes to cleaning and processing of data.

- Set clear expectations. In some cases, you can predict something to a tee, while the predictive capabilities can be limited or significantly different in other situations. You may need invite consultants or discuss a proof-of-concept from your vendor in order to validate your idea. Have clear KPIs and ROI estimation, and make sure they match your business goals.

Our teams have also been working on a complex logistics management system and its integrations with ERP, big data, AI, and more for the Fortune 100 client (under NDA). The company is a global supplier of technology and services. They have engaged the N-iX team to redevelop the logistics platform using AI and scale it globally. The new system aims at automating and simplifying logistics control.

What has been done?

Upon careful examination of the existing algorithms and changes in the architecture, we were able to introduce Continuous Delivery for Machine Learning. It allowed us to implement repeatable cycles of training, testing, and deployment and monitor and operate the ML models. We created AI microservices, based on Kubernetes and Kuberflow pipelines that allowed us to introduce:

- Anomaly detection;

- Delivery prediction;

- Route recommendation;

- Data mining and sensor data processing for BI, statistics. and reporting.

Also, the solution was designed to be cloud-neutral and can also be deployed on-premise.It provides additional flexibility and ability to control the infrastructure expenses.

What we achieved together?

The project is still in the development phase. Apart from complex ML algorithms that bring the computer vision solution to the next level, our development team has also:

- Redeveloped the logistics platform;

- Migrated the monolithic architecture to microservices.

- Automated manual work and reduced paperwork for personnel;

- Streamlined inventory management for 400+ warehouses around the world;

- Automated all stages of deep machine learning development.

- Helped the client with more effective planning, reducing operational overhead and warehouse downtime.

Read more: Machine learning in supply chain: 8 use cases that will impress you

-

Embracing computer vision

In simple terms, computer vision is an ability of a machine or computer to perceive information from an image or video and interpret it. This technology can be used in a variety of ways, including:

- Scanning of barcodes and text labels. 99.99% of any inventory stock nowadays has a barcode. Its scanning is a tedious process that a machine can easily perform. By introducing a computer vision solution, you can enhance the tracking system.

- Labeling, tracking, and tracing. When a product is mislabeled or misplaced, it’s not only about the company losing money or customers not being happy. Let’s look at an example: a mislabeled item may cause trouble if the end-user consumes the wrong medicine or the food they are allergic to. A CV solution can help companies identify such items (e.g., when the label doesn’t match the package type), compare them to the database, and track them.

- Packaging inspection. Companies depend on a certain quality of their product. However, items can be damaged during the production or transportation stage. If we are talking about large inventories (60,000+ SKUs), it is essential to have a system that can automatically find any deviations from the standard. For example, CV-based solution can scan an item from several angles and match it to the desired dataset.

Forrester’s research also suggests that by blending Computer Vision with other technologies, manufacturing companies can create new business outcomes [2].

There are multiple benefits of adding a CV solution to your inventory management software development plan. It can help you:

- Improve stock taking. An automated CV system can track inventory levels. When the stock level is too low, the system can send out an alert. If you add several algorithms, the system can create an automated purchasing order.

- Reduce human errors. CV systems can perform counting and scanning operations with greater accuracy compared to humans.

- Increase productivity. Machines can work 24/7. They don’t need to rest or go on vacation. Automated solutions can significantly increase the turnout.

Related: Computer Vision and Industry 4.0

The same client (see the previous section) has 400+ warehouses, and many assets are moved between these warehouses, shipped, or transferred. The client had a legacy CV solution that proved to be inefficient.

What has been done?

We have designed the architecture of the multiplatform Computer Vision mobile app and handled its end-to-end development. The app enables the company to handle object detection, label recognition, package damage apprehension, OCR (optical character recognition), and NLP for document processing.

We are now working on a multiplatform library with custom neural networks, label detections, data recognition, and data processing on a device based on the Google Firebase API. The library will be used in cross-platform applications and resemble Flutter camera UI responsible for taking pictures and sending post-processing data. It will support online, offline, and mixed modes depending on internet availability.

The challenge was to integrate the Flutter camera plugin with a heavy computational data science pipeline:

- Camera processing;

- Label detection based on TensorFlow Lite;

- Firebase on-device OCR;

- Edit (Levenshtein) distance method;

- Custom label-reading method (OpenCV based template matching);

- Document verification (validates the data from previous steps with the help of NLP methods).

What we achieved together?

- Integrated Flutter camera plugin with a DS pipeline and reused data science components for different platforms.

- Developed and embedded CV for docks. It allows users to manage and track goods in a non-touch manner, including: pallet detection, label recognition, box counting, and fuzzy information matching.

- Engineered an OCR that automatically reads and recognises the information from stickers on packaging and registers it in the system. The NLP part of the solution allows document verification.

- Created a PoC of a loader management system, It allows an automatic scan of large pallets and eliminates manual labor.

-

Rise of internal and 3P integrations

Inventory management systems rarely exist on their own. In most cases, the company would integrate them with internal systems like SAP or internal ERP. In others, inventory management systems will require third-party integrations to unlock new business opportunities. Here are some of the use cases:

- Real-time stock availability. Nearly 80% of shoppers prefer to go to the physical store rather than order online, when they see the store has the item needed[5]. People still like the in-store shopping experience. So it would help if you hooked up your inventory management software to your website to show the availability of the item in a specific store or how fast it can be delivered there.

- Multi-channel order alignment. Let's take a retail business as an example. Typically, the company would use its website and 3P platforms like Amazon to sell its goods. They can also receive orders from their social media or have a sales department that can be placing orders on behalf of their clients. To manage everything effectively, the system should have integration with inventory in real-time.

- 3P logistics and shipping systems. Recently, companies are talking more about outsourcing the ‘last mile shipment’ to third parties. It means that the requested item is delivered to a storage facility or depot, and it is picked up by a 3P services provider to be delivered to an end client.

How to develop inventory management software?

- Gather and analyze the requirements. You need to collect information and input from as many stakeholders as possible. Then group them into specific features. If possible, try to predict future integration with systems in the company. If you have no resources to handle this in-house and plan to outsource, ask your vendor about the product discovery phase.

- Make reasonable time estimations. A simple system takes from 9 to 18 months of development, whereas more complex systems will require more time or more developers involved.

- Hire a development team or outsource. Whether you decide to hire an in-house team or outsource development, opt for experts with previous experience in developing this sort of solution.

- Test the system. Once you have the product, make sure every module is tested and works according to specifications.

- Schedule maintenance. As with any other system, inventory management software requires regular support from a development team.

How to choose the best inventory management software development company?

Despite a large number of out-of-the-box software solutions for inventory management, many companies need to develop a customized system. But where do you begin?

- Explore different outsourcing destination

When you are looking for an outsourcing location, make sure to look for the one with an established reputation. Typically there are three major outsourcing destinations: Eastern Europe, Asia, and South America. Here you can find a side-by-side comparison of these three locations.

- Research the potential partners

Once you have selected the country for inventory management software development, you need to create a long list of vendors. You can begin by googling the companies that offer specific services or checking out dedicated directories under the respective category. Make sure to check reviews, clients' testimonials, and case studies. In one of our articles, we have created a 15-step guide on finding the best vendor.

- Evaluate technical expertise of vendors

Analyze your tech stack and look for companies that have relevant offerings. If you plan to introduce complex data analytics, look for a firm with strong Big Data, BI, and data science expertise. If you plan to move your solution to cloud or need a hybrid cloud, then a strong cloud expertise is a must. You may also need to engage architects to audit the system or DevOps to help you set up the infrastructure.

- Choose the vendor with a strong portfolio

You can have many criteria for vendor selection, but remember to look for a company that has successful cases of developing inventory management software. Their technical expertise should match your expected tech stack. You can also request a discovery phase or discuss the proof-of-concept.

Why choose N-iX for inventory management software development?

N-iX is one of the largest Ukrainian companies with a strong portfolio of manufacturing, logistics,and supply chain projects. Our expertise includes custom software development, Big Data engineering, BI, Data Science, AI/Machine Learning solutions, and more.

- We have over 21 years of experience in the IT market and build long-lasting, strategic partnerships with our clients.

- A pool of 2,200+ experts that have experience working with business cases of different complexity and size.

- N-iX is compliant with international regulations and security norms, including ISO 27001:2013, PCI DSS, ISO 9001:2015, GDPR, and HIPAA.

- The company is listed among the top software development providers by Clutch, in the Global Outsourcing 100 by IAOP for 7 consecutive years, recognized by GSA UK Awards, included in top software development companies by GoodFirms.co, and others.

References

- Enterprise Mobility Management Market Size by Global Market Insights.

- All Enterprises Need (Computer) Vision, Forrester Research, Inc., June 14, 2019.

- Emerging Technology Spotlight: Computer Vision , Forrester Research, Inc., December 10, 2018.

- Regulating the internet giants - The world's most valuable resource is no longer oil, but data by The Economist.

- Google/Ipsos, U.S., “Shopping Tracker,” Online survey, n=3,613 online Americans 13+ who shopped in the past two days, Oct.–Dec. 2017.

Have a question?

Speak to an expert