Logistics have embraced digital transformation more slowly, compared to other industries. However, with the global pandemic, increase in ecommerce and decrease in offline retail, the traditional supply chain and logistic activities had to change. Companies are dealing with growing costs, have troubles scaling their processes, unable to predict the demand, and rely heavily on manual labor. And now is the high time for innovation.

Digital transformation is the main disruptor in the logistics industry and will account for $1.72T in investments that are to be allocated to logistics by 2025 [1]. Innovation is inevitable for the industry to survive and thrive. In this article, we are going to to take a look at:

Innovation in logistics: market analysis

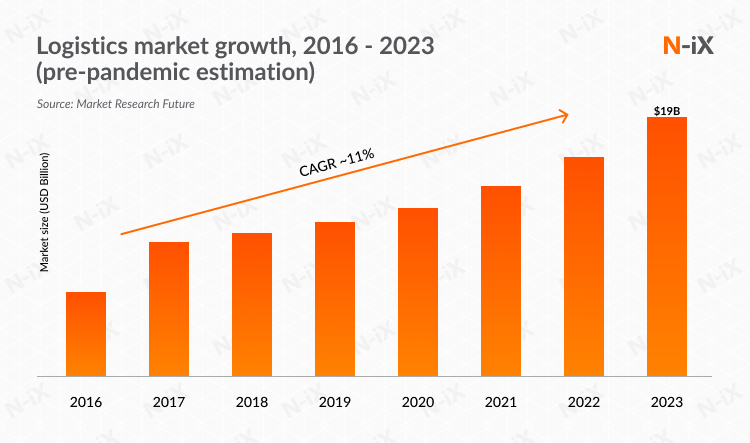

Gartner experts suggest that the financial impact of the pandemic will vary between $2T and $4.5T in the global scale. While the pre-pandemic estimation set the market growth for the logistics industry at $19B in 2023, it is now projected to reach $12.9B by 2027, registering a CAGR of 6.5% from 2020 to 2027.

Despite some setbacks, the industry is recovering and looking for innovation. So what are the major trends in logistics?

3 major trends in logistics

Logistics Trend Radar [3] shows that innovation in logistics will correlate with social and business trends, as well as technological advancements. Logistics companies plan to automate as much as possible, make their processes more flexible, and improve sustainability of their operations.

1. Hyper automation

The global pandemic has forced companies to embrace automation. Hyper-automation is a combination of various technologies that aim to enhance logistics efficiencies. Its major goal is to create a seamless transition between various areas: sales, suppliers, planning, purchases, and distribution, while also reducing human involvement.

Let’s take a look at an example of cognitive automation. It’s a combination of several technologies, e.g. AI + OCR (Optical character recognition) + RPA (robotic process automation). The combination of AI and OCR allows you to handle unstructured sales orders. Then you add this model to your RPA, and you can process information from and order, find items, and transport them - all without human involvement.

2. Elastic logistics

Elastic logistics allows companies to scale the supply chain operations up or down depending on the market demand. It is specifically designed to withstand fluctuation periods and manage the operations with more efficiency. Some of the most common challenges this trend tackles are underutilization of vehicles, warehousing limitations, and overstocking. Some of many advantages of elastic logistics include:

- Optimized routes and enhanced transport efficiency;

- Reduced over-manufacturing and over-stocking risks;

- Improved control over the price volatility;

- Increased efficiency throughout various checkpoints of supply chain;

- Improved customer service.

Elastic logistics relies heavily on predictive data analytics, ML algorithms, and AI.

3. Green logistics

Often called an eco-logistics, this trend refers to a variety of measures and policies set to reduce the environmental impact on transportation, warehousing, and other logistic activities. The main goal is to coordinate all the activities and have them implemented in a way that benefits the economy, the environment and the society. Among the major forces that drive this trend are high dependency on fossil fuels, transport logistics impact of urban traffic, carbon footprint, energy-guzzling warehouses that demand 24/7 human involvement, and much more. So what are the steps that the industry leaders are taking to combat these issues:

- Optimization of fleet management. There are two things that can be done: better route planning and improvement of load planning.

- Sustainable warehouse management. Automation of certain processes, focus on energy saving, limit of resource wastage,

- Improved stock management and reverse logistics processes can be achieved in many ways including optimization of picking plants, introduction of robots and automated machinery, or well-planned reverse logistics.

And while these trends are important from both environmental and economic standpoint, how are they realized in real life? What technological advances are driving these trends?

Tech trends that power innovation in logistics

As an industry that was one of the most resistant to change, logistics has a lot of catching up to do. According to recent research [2], the top five most promising technologies that are boosting innovation in logistics are IoT, AI, robotics, warehouse automation, and Blockchain.

We will also look at some other technologies that can boost the innovation in the logistics industry.

-

Internet of Things

IoT is a huge thing in the digital world. It helps the companies enhance the visibility of their supply chains. Some companies fit their fleet with sensors to achieve real-time tracking updates on shipment and delivery. They can also improve the location and route management. In warehouses, IoT solutions can improve visibility into inventory management, storage conditions, and predictive maintenance. With an introduction of 5G, this tech trend seems to be the most promising.

-

Cloud computing

Cloud has been a buzz for quite some time and finally, logistics is accepting it as well. Cloud allows the companies to scale up or down, based on the demand or market situation. Whether companies opt for Cloud-native or hybrid environments, it also serves as a backbone for adoption of virtually any modern technology. One of the major benefits of Cloud adoption is the ability to centralize analytics while decentralizing data collection and accessibility.

-

Artificial intelligence and machine learning

Due to the rapid development of machine learning, computing power, and big data analytics, Artificial Intelligence (AI) is finding strong adoption within the industry. While implemented properly, AI helps companies to improve the operation's functionality, find the possible problem, and offer solutions. According to research [4], AI adoption in logistics can increase companies' profits by up 5-10% a year. Market leaders raise the investments in AI technologies for saving money and time in the future.

Machine learning algorithms are becoming more and more popular. Industrial acceptance of ML was boosted by the development of Cloud technologies and expansion of computing powers. As of 2020, McKinsey’ study revealed that nearly 20% of enterprises have some form of ML embedded in their processes. It helps companies reduce manual work, optimize costs, and enable intelligent decision making.

-

Computer Vision

Barcode scanning remains the dominant method of item tracking throughout the logistic chain. By enabling computers and scanners with an ability to perceive information from graphic resources like images or video, companies can significantly improve the processes. CV solutions offer far better results, compared to traditional laser scanners. They can read labels that are damaged, fuzzy, warped, or poorly printed with more accuracy. By combining CV with other technologies, businesses can unlock even more value.

You may also like: Computer Vision and Industry 4.0

-

Robotic process automation

Robotic process automation (RPA) has made a huge leap in development over the last couple of years. Driven by technological advancements and greater affordability, robotic solutions are entering the logistics. Autonomous mobile robots assist humans in warehousing and offload of inventory, Automated guided vehicles and carts (AGVs and AGCs) transport items within the warehouse or between the facilities. Many companies are even testing aerial drones for the last mile delivery.

-

Digital twins

This technology creates a digital copy of a physical object or process. It can have multiple practical uses in logistics. Warehouses can use this technology to create accurate 3D models of their storage facilities and experiment with layout changes with no need to move a single item. Logistics hubs can create digital twins and use them to test routes, schedules, and increase efficiency. In addition to that, delivery networks could use the technology to provide real-time information that will improve delivery times and further aid autonomous vehicles in their routes.

-

Blockchain

Despite the fact that Blockchain is one of the most overhyped technologies, its practical application can actually be of a great value for logistics companies. If created properly, Blockchain platform can serve as a transaction ledger. For a company that might be using several vendors or 3P services, this system would help different carriers to share sensitive data without the fear of it being leaked or corrupted. However, in order to achieve that, companies need to digitize, standardize, and clean their data. Once the industry-wide standards are implemented, companies will have to create an ecosystem of supply chain partners that can use the blockchain environment.

-

Data standardisation and advanced analytics

Logistics companies gather a lot of information. However, the vast majority of it can be siloed or not shared between different units. However, in 2021, it's no longer an option. Companies that want to succeed need to change the way they treat data. With the introduction of new data standards for container shipping by DCSA and its Industry Blueprint, they’ve set the ground for the industry-wide change. More and more companies choose to cleanse their data and transform it into advanced analytics. It will help them get better supply chain visibility, improve demand forecasting, perfect the last-mile delivery, and much more.

-

Warehouse automation

With the worldwide pandemic and an ever-increasing need to reduce human involvement in all the processes, the numbers will grow even more. More and more companies are choosing mobile robots, advanced data analytics and prediction, as well as Computer vision solutions in order to reduce the level of human involvement. The combined efforts allows companies to reduce processing time and speed up delivery, while also reducing the chances of human errors.

Read more: Automation in inventory management: case studies, trends, and more

-

Last-mile delivery systems and 3P integrations

Last-mile delivery is one of the biggest pains of logistics. How do you optimise the routes? How do you cut the costs? How can you make the customers happy? All these questions force many companies to consider third-party logistics and shipping systems. And even more companies choose 3P systems for last-mile delivery. However, a proper integration of these services with your internal order management systems requires a lot of time and resources.

Adopting innovation in logistics: success stories

Many industry leaders have already started their journey in digital transformation. They plan to improve their analytics, introduce new technology, and gain better visibility into every process. Today we would like to share two stories of how N-iX is helping companies bring innovation to their logistic activities.

-

Full-stack industrial IoT solution for industrial fleet tracking and management company

The company (under NDA) is an international company that specialises (among other things) in smart telematics and related solutions for efficient fleet operation and management. The company. chose N-iX as their R&D partner to implement a full-stack IoT solution and increase customer reach.

Value delivered

Our team did deep research and feasibility studies before development. Now we are working on gateway development and application development.

The OEM-based Linux connectivity gateway is installed in the vehicle for monitoring and management of vehicle activities tracked by a GPS system. Information from each vehicle is monitored, analyzed, and stored for future reference. This system allows users to access vital information, including the speed the vehicle is traveling at, fuel consumption, engine efficiency, etc.

The N-iX team has helped the client with solution architecture design and full-scale implementation of the OEM-based Linux connectivity gateway. We integrated it with a Google Cloud-based IoT platform and existing customer services to launch a new product in the client's ecosystem.

New app development. The N-iX team is also involved in the development of an Android app with a management panel available for the driver. It includes messaging, device onboarding, connectivity control, and user control.

The cooperation started early in 2021 and is ongoing. So far, our team has developed a new full-stack IoT solution for industrial fleet tracking and management companies, allowing our client to certify the product and engage new customers.

-

Logistics platform redevelopment for Fortune 100 engineering company

Our client (under NDA) is a multinational engineering and technology company, based in Europe. As a leading global supplier of technology and services, the client has many factories, warehouses, and suppliers, as well as a lot of raw materials and finished goods, which circulate among them. The company had an internal logistic platform that was used by warehouse staff to allocate and manage goods and materials. However, it wasn’t efficient enough and was unsuitable for further scaling. They have engaged N-iX to redevelop the logistics platform using AI and scale it globally.

Value delivered

Due to the monolithic architecture of the legacy platform, one of the first things that needed to be done is migration to microservices. Our Solution Architect designed and presented a new cloud-native infrastructure of the platform, along with the suggested tech stack and the most efficient roadmap.

Once the system was migrated to microservices, we were able to add new SaaS services: anomaly detection, delivery prediction, route recommendations, object detection in logistics, OCR (optical character recognition) of labels on boxes, NLP for document verification, data mining, and sensor data processing.

Our client also lacked DevOps expertise. Therefore, we are building the DevOps pipeline from scratch, setting up the environment for development and QA, and introducing CI/CD processes that allow us to easily assemble and deploy microservices to the environment.

Computer Vision solution. The core component of this project is the Computer Vision (CV) solution for docks that allows contactless tracking of goods with industrial optic sensors and Nivida Jetson devices.

Upon careful examination of the existing algorithms, we decided to redevelop them. We recommended changes to the architecture of the solution and introduction of Continuous Delivery for Machine Learning. It helped us to implement continuously repeatable cycles of training, testing, deploying, monitoring, and operating the ML models.

N-iX team has designed the architecture of the multiplatform CV mobile app and is responsible for its end-to-end development. The app covers object detection, package damage detection, OCR, and NLP for document processing.

Let N-iX help you bring innovation to logistics

- N-iX is a global software development vendor with a strong portfolio of manufacturing, logistics, and supply chain projects. Our expertise includes custom software development, Big Data engineering, BI, Data Science, AI/Machine Learning solutions, and more.

- N-iX complies with international regulations and security norms, including ISO 27001:2013, PCI DSS, ISO 9001:2015, GDPR, and HIPAA, so your sensitive data will always be safe.

- The company has been listed among the top software development providers by Clutch, in the Global Outsourcing 100 by IAOP for 4 consecutive years, recognized by GSA UK 2019 Awards, included in top software development companies by GoodFirms.co, and others.

- N-iX has been named No. 72 on the 2020 CRN Fast Growth 150 List for the substantial growth and performance over the previous two years.

- We have almost 21 years of experience in the IT market and build long-lasting, strategic partnerships with our clients.

References:

- The digital transformation of logistics: Threat and opportunity. http://reports.weforum.org/digital-transformation/the-digital-transformation-of-logistics-threat-and-opportunity/.

- Top 10 Logistics Industry Trends & Innovations in 2021 by StartUs Insights. https://www.startus-insights.com/innovators-guide/top-10-logistics-industry-trends-innovations-in-2021/.

- Logistics Trend Radar. Delivering Insight Today. Creating Value Tomorrow by DHL. https://www.dhl.com/global-en/home/insights-and-innovation/insights/logistics-trend-radar.html.

- Global AI Survey: AI proves its worth, but few scale impact by McKinsey & Company. https://www.mckinsey.com/featured-insights/artificial-intelligence/global-ai-survey-ai-proves-its-worth-but-few-scale-impact.