For businesses relying on production, process downtime is expensive and disruptive. It's also avoidable if one has visibility into machine operations.

But how to acquire said visibility? The answer is predictive maintenance. Powered by the Internet of Things (IoT), through various types of sensors, such maintenance helps minimize downtime while improving operational efficiency.

IoT in predictive maintenance can help companies increase visibility into operations and equipment condition and achieve other benefits along the way. At the same time, the path to adopting these technologies for predictive purposes has challenges that should be dealt with. This guide shows you what's possible and what to watch out for when you integrate IoT solutions into your maintenance strategy.

What role does IoT play in predictive maintenance?

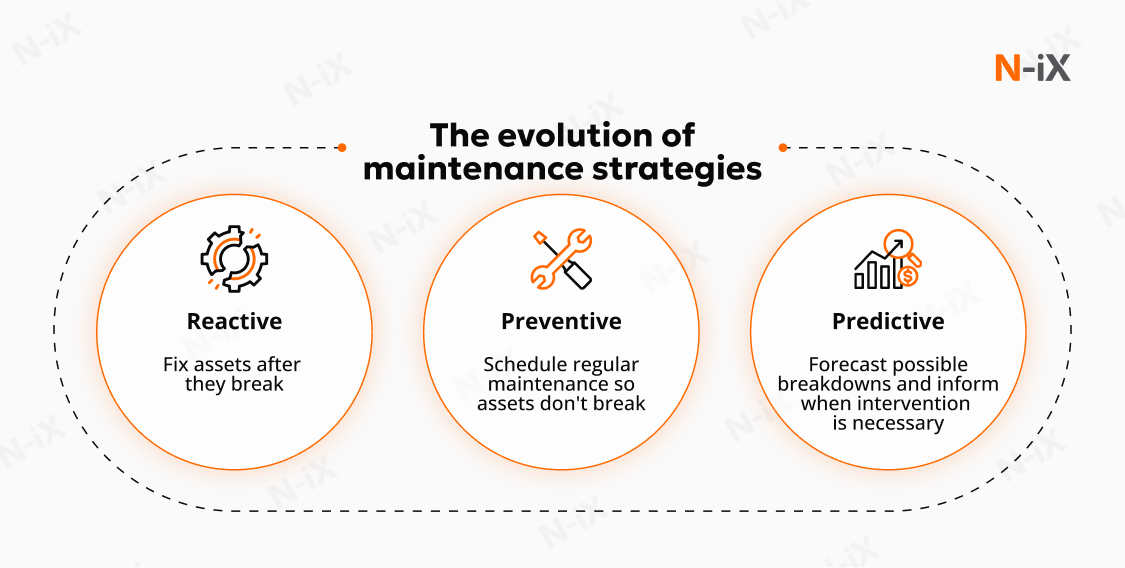

Predictive maintenance helps prevent equipment from unexpected breakdowns and allows manufacturers to act before small issues turn into extended downtime. Unlike reactive maintenance (fix after failure) or preventive maintenance (scheduled service at fixed intervals), predictive maintenance ensures that assets are serviced only when needed. This approach helps cut unnecessary costs and reduce downtime.

The Internet of Things in predictive maintenance allows businesses to retrieve data that can indicate the need for maintenance. By monitoring performance in real time, companies can detect anomalies, predict potential failures, and schedule maintenance before costly downtime occurs. Here's what it takes to build an IoT-based predictive maintenance system.

Key components of IoT predictive maintenance systems and how they work

An IoT-enabled predictive maintenance system requires a few core ingredients to turn information into insights. They include:

- IoT sensors and edge devices. They capture real-time data on machine health (e.g., vibration, temperature, oil quality, ultrasonic signals) and often process it locally at the edge to reduce latency.

- Connectivity. Protocols and networks such as 5G, LPWAN, MQTT, or satellite enable reliable data transfer for remote equipment, ensuring machines stay connected anywhere.

- IoT platforms and cloud analytics. Cloud-based platforms like AWS IoT, Azure IoT, GCP, or ThingWorx collect, store, and analyze sensor data at scale, providing dashboards and alerts.

- AI/ML predictive models. Machine Learning algorithms detect anomalies in equipment behavior and forecast failures, allowing maintenance to be scheduled proactively.

- Integration with CMMS/ERP/EAM systems. Sending insights into systems like computerized maintenance management systems (CMMS), enterprise resource planning (ERP), or enterprise asset management (EAM) systems enables automated work orders, spare part planning, and seamless workflow execution.

A system featuring these components can help businesses achieve various advantages.

Business benefits of predictive maintenance using IoT

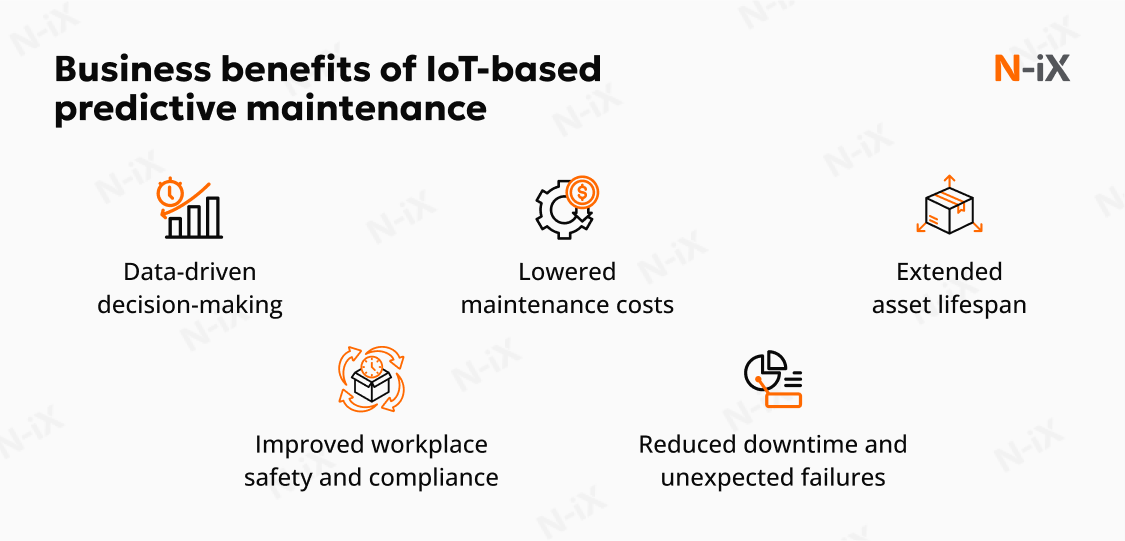

Predictive maintenance with IoT helps businesses better understand their assets' performance and plan interventions into processes and budgets. It eliminates some uncertainty and allows businesses to become more flexible and adjustable. Here's how implementing IoT-driven predictive maintenance brings tangible business benefits.

Reduced downtime and unexpected failures

IoT sensors track the health of critical assets, allowing for real-time monitoring and providing immediate insights into any anomalies. By detecting early signs of wear or failure, businesses can take action before issues escalate. As a result, such a proactive approach minimizes downtime and supports production schedules. For example, as the McKinsey report states, adopting IoT in a manufacturing platform helped BMW reduce the downtime of its press shop by 25% [1].

Explore further: IoT in smart manufacturing: Insights for enterprises

Lowered maintenance costs

Instead of adhering to a fixed maintenance schedule, IoT predictive maintenance helps businesses service equipment when sensor data indicates a deviation from the optimal threshold. This way, businesses can reduce unnecessary maintenance tasks and cut labor costs. It also prevents over-servicing. The result is a more efficient resource allocation and a reduction in overall maintenance expenses.

Extended asset lifespan

By using IoT sensors to monitor equipment condition, the companies can track specific metrics like temperature, vibration, pressure, and others in real time. Continuous monitoring ensures machinery runs smoothly and alerts maintenance teams when intervention is required. Regular assessments based on actual equipment performance help extend the lifespan of assets by preventing premature wear and tear.

Improved workplace safety and compliance

Predictive maintenance using IoT also enhances workplace safety by identifying potential hazards before they cause accidents. IoT sensors can detect mechanical issues or environmental changes that could lead to malfunctions or failures. It enables businesses to address safety concerns proactively and prevent accidents. Additionally, monitoring equipment conditions helps ensure compliance with industry regulations by maintaining the standards necessary for safe operation.

Data-driven decision-making

IoT predictive analytics tools aggregate and analyze data from connected assets, providing businesses with actionable insights. The advanced analytics dashboards allow decision-makers to view the health of their assets at a glance and base maintenance decisions on data rather than intuition. As a result, it fosters a more strategic approach to asset management.

These benefits are among the top priorities for many businesses seeking process optimization. Here are a few use cases that justify IoT deployments in predictive maintenance.

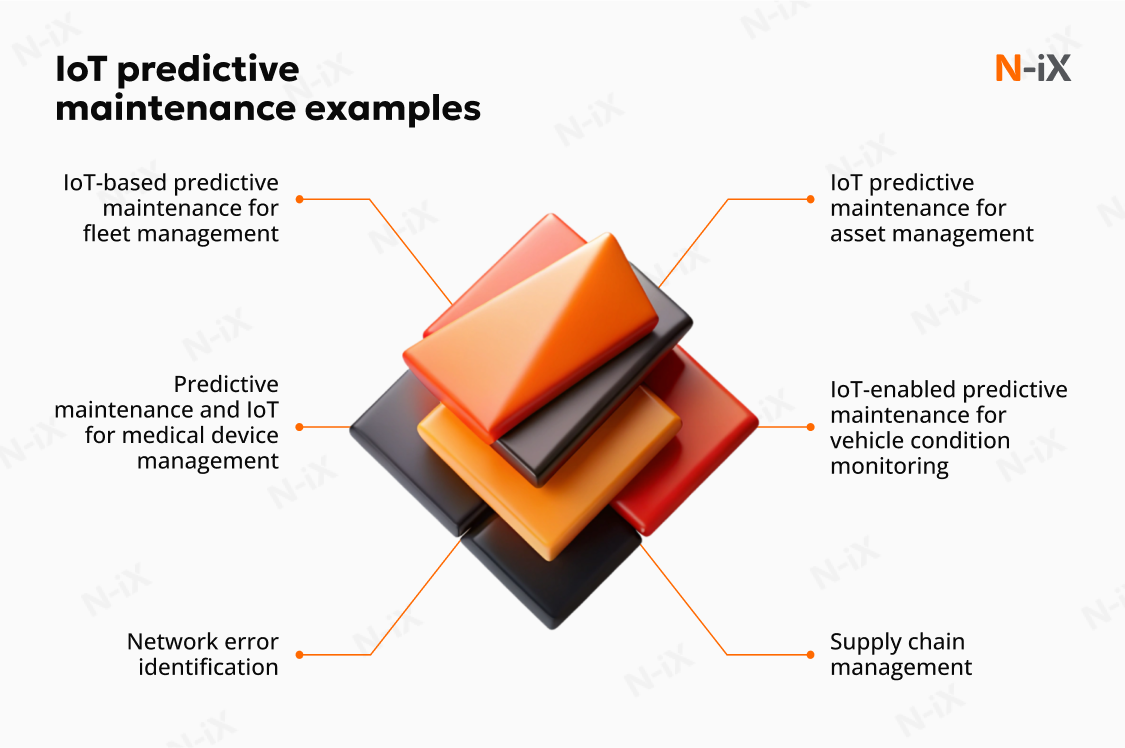

Predictive maintenance IoT: Use cases and examples across industries

Any business with expensive machinery, fleet, or other assets for production or service provision wins from predictive maintenance. This approach is critical for operations and market success in industries that usually include automotive, logistics, healthcare, manufacturing, telecom, energy, aerospace, and others. Let's review a few use cases of predictive maintenance with IoT and examples across industries.

IoT-based predictive maintenance for fleet management

With IoT in predictive maintenance solutions, you understand where your vehicles are, their status, and who is responsible for driving and caring for them. An IoT-based fleet management system can help your business with telematics (transmitting, storing, and receiving data from devices over a network) and alerts. For example, IoT sensors help run vehicle diagnostics and fleet telematics extensions to work as a tool for predictive maintenance. This allows fleet managers to oversee fleet performance providing a high-level view of each unit.

More on topic: IoT fleet management: Operate your assets smarter

IoT-enabled predictive maintenance for vehicle condition monitoring and management

Efficient industrial IoT predictive maintenance for vehicle monitoring calls for reliable data for analysis and predictions. IoT sensors provide up-to-date data on the state of vehicle parts as well as send Diagnostic Trouble Codes (DTCs) that track existing mechanical failures.

For example, oil and lubricant sensors, thermal imaging sensors, and those that enable vibration, sonic, or ultrasonic analysis enable fuel consumption, engine temperature, fluid levels, and run time monitoring. This condition-based monitoring helps the fleet management team plan vehicle use and maintenance without disruption.

N-iX case study: Our client, a UK-based car dealership company (under NDA), represents prestigious car manufacturers, including Jaguar, Audi, BMW, Mercedes-Benz, and more. It provides new and used cars, and post-sales services for its clients. Our client needed to enhance equipment uptime and cut maintenance costs, so they've partnered with us to develop an IoT predictive maintenance solution.

Collaborating with the client's development team, our experts helped create a solution based on vibration data collected from pumps, motors, gearboxes, fans, and more. The data is collected either with handheld devices during the inspection rounds or with online sensors permanently installed on the machine. The experts choose the approach depending on the available data, quantity, quality, type, etc.

Predictive maintenance and IoT for medical device management

Predictive maintenance in medical devices helps avoid service interruption due to unplanned device services. IoT sensors gather data on the state of devices like bladder scanners, blood pressure monitors, wheelchairs, and defibrillators. This data gets analyzed, and with the help of the gained insights, experts identify what devices should be inspected or repaired.

N-iX case study: WEINMANN Emergency is a German medical technology company that develops medical equipment, including oxygen systems, portable ventilators, and defibrillators.

The N-iX team and the client have developed telemetry support for the smart defibrillator MEDUCORE Standard². This feature helps prevent device failures related to defibrillation and monitoring. Maintenance experts can monitor equipment health and identify issues with device sensors and their core components based on a range of indicators.

Related: Internet of Medical Things: Executive's guide

IoT predictive maintenance for asset management

Modern plants require costly equipment and maintenance, making machine failures even more expensive, as production halts lead to significant financial losses. Real-time condition monitoring, powered by IoT devices, allows manufacturers to get insights into the state of devices and prevent asset malfunction. For instance, if a machine heats more than it should while working, there is a risk of failure. IoT sensors that track temperature alert the system, and experts check on this device.

N-iX case study: Fluke Corporation is a global manufacturer and distributor of electronic test tools and software. The company partnered with us to develop several secure, reliable, and scalable solutions for enterprise asset management.

N-iX experts needed to implement reactive and preventive maintenance workflows. To do that, we have developed mobile solutions with top-notch offline support that interoperate with PLC/SCADA and CMMS systems. In addition, N-iX specialists have implemented the system supporting new industrial protocols that enable condition-based asset maintenance.

Supply chain management

Companies are ready to invest in predictive analytics in the supply chain to achieve increased visibility into operations and cut down expenses. IoT predictive maintenance in supply chain management helps track equipment condition, detect inefficiencies, prevent supply chain interruptions, and address potential risks.

Network error identification

Fixing network errors precisely and quickly is the primary way to improve the quality of services. It holds especially true for the telecom industry. Businesses use IoT-enabled predictive maintenance and other technologies (e.g., big data) to predict network failures. With the help of predictive maintenance using IoT, telcos can maintain radio nodes in different locations, controlling the time and cost of the upkeep by pre-planning.

With various use cases of how IoT improves predictive maintenance, you should also remember that IoT implementation has challenges. Let's look at what you should be ready for and how to navigate the journey confidently.

Harness AIoT for smarter operations—get the guide to industry use cases!

Success!

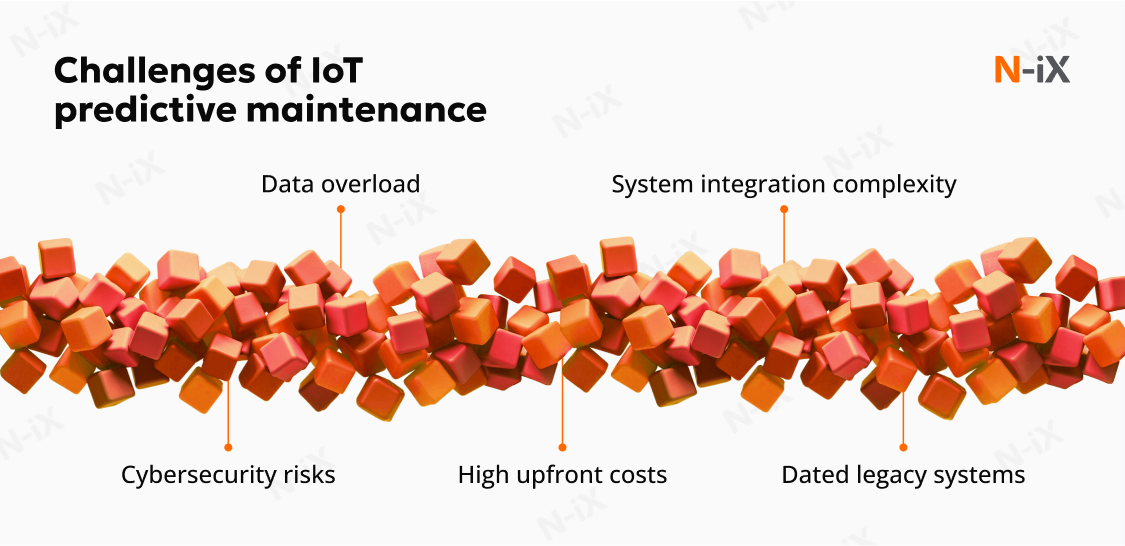

Challenges of IoT predictive maintenance and how to deal with them

Implementing IoT-powered predictive maintenance at scale has its difficulties. If not addressed at the planning stage, their escalation can adversely affect the project. Let's review what you should consider when adopting IoT for predictive maintenance.

Data overload

IoT sensors generate massive amounts of data on vibration, temperature, pressure, and other indicators. Without advanced tools capable of processing data, businesses risk drowning in information and missing critical signals.

How N-iX can help: Our teams build predictive analytics pipelines that filter sensor noise, prioritize key metrics, and apply AI/ML models for anomaly detection. We design cloud-native AWS, Azure, or GCP solutions to ensure scalability and real-time insights. For example, we delivered IoT solutions that process high-frequency sensor data for Fluke, a global leader in electronic test tools. It enabled operators to detect failures early.

System integration complexity

Due to limited unification, connecting IoT sensors, gateways, and cloud platforms with ERP, CMMS, or EAM systems is often complex. In addition, legacy protocols and siloed infrastructure can delay the adoption of predictive maintenance.

How N-iX can help: We specialize in bridging old and new technologies through custom middleware, open standards (MQTT, OPC UA), and API-driven architectures. We also have experience in integrating SCADA/PLC systems with modern IoT analytics for a global manufacturing client. It enabled predictive workflows across distributed plants without disrupting existing operations.

Cybersecurity risks

Every connected sensor increases the attack surface. Firmware, connectivity, or cloud components vulnerabilities can expose sensitive operational data and cause downtime. According to Eseye's report, over 26% of respondents named device security the biggest challenge for IoT adoption [2].

How N-iX can help: N-iX embeds security from the ground up. We run penetration testing, adopt DevSecOps pipelines, and ensure compliance with ISO 27001, SOC 2, and GDPR. Our IoT security services help design predictive maintenance platforms with end-to-end encryption, secure device identity, and continuous monitoring, ensuring your data and assets stay safe.

High upfront costs

IoT predictive maintenance requires investment in sensors, infrastructure, and analytics. Without a phased strategy, businesses risk high costs before seeing returns.

How N-iX can help: We help companies start small with pilot projects to validate ROI before scaling. Our engineers use cloud platforms with pay-as-you-go scalability, avoiding heavy upfront spending. During our long-term partnership with Fluke, we've proven that a pilot-first approach in industrial IoT projects reduces financial risks while setting the foundation for scalable IoT predictive maintenance.

Explore top 15 industrial IoT use cases that improve operational efficiency

Dated legacy systems

Older machines and enterprise software often lack IoT connectivity or compatibility with predictive platforms. Replacing them with new ones is expensive and disruptive.

How N-iX can help: We retrofit legacy equipment with IoT gateways and protocol converters, allowing it to communicate with modern IoT devices and cloud platforms. Our hybrid IoT architectures enable businesses to modernize gradually without costly replacements or downtime. This approach allows manufacturers to extend the life of their assets by integrating them into predictive ecosystems.

While these are typical challenges across industries, you should consider the issues specific to your business or industry, such as the tech ecosystem or regulations. The right tech partner, like N-iX, can help you design a holistic approach that solves your current business tasks and prepares you for future transformations. Let's review the trends you should consider today if you build for tomorrow.

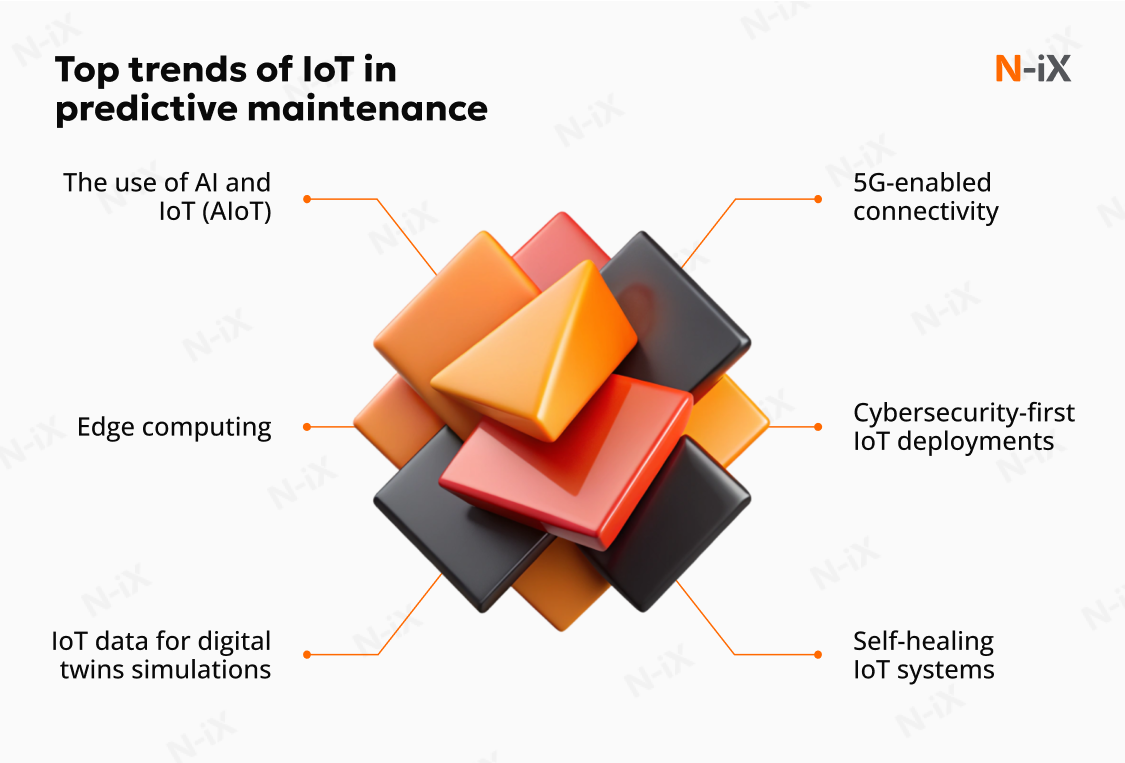

Trends shaping the future of IoT in predictive maintenance

The use of AI and IoT (AIoT)

If IoT technology enables sensor data analytics and transmission to the processing platform, AI helps make sense of it. Together, these technologies create connected systems that send the data and act upon it. Sometimes, to cut cloud costs, businesses turn to on-device AI, i.e., moving the AI/ML components closer to the data source. By combining IoT sensors with AI algorithms, businesses can go beyond simple alerts to predict failures before they occur. AIoT applications detect subtle vibration, temperature, or fluid data patterns that employees could overlook.

According to Eseye, there will be 9.1B AIoT connections by 2033 [3]. It shows the need for businesses to adopt advanced technologies to stay competitive. The company expects that AI will be mainly used across device-level processing, the application, and the networking layers in IoT to make predictive maintenance and analytics possible.

Edge computing

Sending all IoT data to the cloud can be slow and expensive. Edge computing allows data to be processed directly on or near the equipment. It enables instant anomaly detection and faster responses, which are crucial for assets in remote areas or safety-critical environments. It also reduces bandwidth costs and reliance on always-on connectivity.

IoT data for digital twins simulation

The concept of digital twins relies on data from a physical asset. IoT-powered sensors and devices send asset data to the digital twin platform, helping companies run simulations, test different scenarios, anticipate failures, and optimize maintenance schedules. In addition, digital twins allow engineers to experiment without disrupting real operations.

More on topic: Best practices for effective IoT data visualization

5G-enabled connectivity

With a large volume of IoT data needed for predictive maintenance, the companies seek the most optimal IoT connectivity options to transmit it. 5G networks provide the bandwidth and ultra-low latency required to support thousands of connected devices simultaneously. This makes real-time monitoring and predictive analytics feasible even in highly dynamic environments like factories or logistics hubs.

Cybersecurity-first IoT deployments

More countries worldwide are now enforcing cybersecurity requirements for manufacturers. The EU, for example, has adopted the Cyber Resilience Act (CRA) to protect consumers of products with digital components. It will make the manufacturers redesign their processes to match cybersecurity requirements.

As more assets become connected, they also become potential entry points for cyberattacks. Predictive maintenance systems must be secure by design, with end-to-end encryption, secure device identities, and continuous vulnerability monitoring. Without this, even the best predictive models risk being compromised.

Self-healing IoT systems

The future of maintenance is not just prediction but also automated prevention. IoT systems use AI-driven automation to adjust operations when anomalies are detected. For example, the machine automatically slows down, redistributes loads, or shuts down if any warning patterns are detected to avoid failure. It minimizes downtime and human intervention.

Businesses should follow a well-defined strategy that includes key steps to ensure a smooth and successful implementation. Below are essential tips to consider when adopting IoT in predictive maintenance.

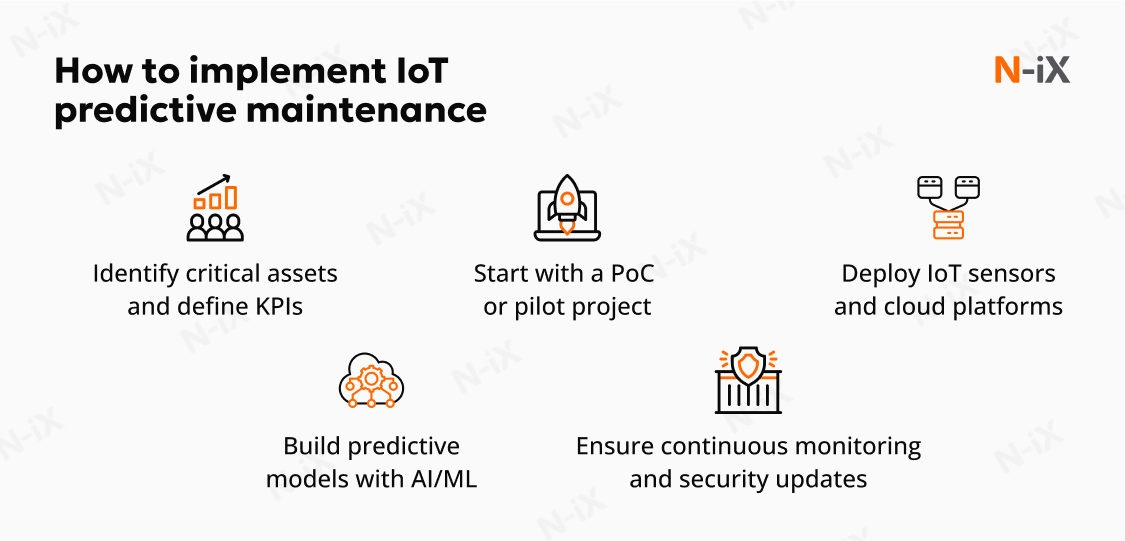

Top tips for successful implementation of IoT in predictive maintenance

Identify critical assets and define KPIs

Identifying your critical assets (machinery, equipment, or systems) is the first step in IoT-based predictive maintenance. Once you've identified them, define the key performance indicators (KPIs) you want to monitor. The list may include:

- Mean Time Between Failures (MTBF);

- Overall Equipment Effectiveness (OEE);

- Downtime;

- Other relevant KPIs for your environment.

These KPIs are crucial in understanding equipment health and performance. They help you prioritize maintenance activities, streamline resource allocation, and track improvements. For example, MTBF and OEE will help you assess machine reliability in manufacturing, while reducing downtime ensures optimal production output.

Start with a PoC or pilot project

Before fully committing to IoT-enabled predictive maintenance, conduct a Proof of Concept (PoC) or pilot project on a small but critical segment of your assets. For example, an automotive company could test predictive maintenance on a specific set of vehicle parts before implementing it across the fleet.

Use the PoC to validate your IoT setup, data collection methods, and maintenance predictions, and ensure your team is aligned on the pilot's objectives and KPIs. This will allow you to test the system's viability, identify potential issues, and ensure that it meets your expectations.

Deploy IoT sensors and cloud platforms

IoT sensors are crucial for monitoring asset health. Choose the right sensors based on the type of asset and the parameters you need to monitor (temperature, vibration, pressure, humidity, etc.) These sensors collect real-time data, which is sent to cloud platforms for storage and analysis. Ensure that IoT sensors are installed across critical assets for consistent data collection, and they are smoothly transferred to cloud platforms (AWS, Azure, or GCP) for real-time data analytics and reporting.

Explore further: The Internet of Robotic Things: Key use cases and benefits

Build predictive models with AI/ML

Artificial Intelligence (AI) and Machine Learning (ML) help forecast potential failures or performance issues. To build one, you need to collect sensor data and feed it into AI/ML models. You should use historical data to train the models and continuously refine them to improve prediction accuracy.

Ensure continuous monitoring and security updates

IoT devices and predictive models evolve, and regular updates ensure the system functions optimally. For example, the system may lose accuracy if new data from newly added sensors is not incorporated into the predictive models. Additionally, security updates protect sensitive data from cyber threats. To keep the IoT systems reliable, set up real-time monitoring dashboards to track asset health continuously and implement regular security patches and updates to safeguard your data.

How N-iX can help you with IoT predictive maintenance

With N-iX as your partner, predictive maintenance becomes proactive, reliable, and tailored to your operations. We bring over 23 years of software development experience, 2,400 software engineers, and deep IoT and AI expertise to help enterprises improve predictive maintenance solutions. With our experts by their sides, our clients have reduced downtime, optimized resources, and improved operational efficiency.

Our approach covers the full development lifecycle: from IoT consulting and PoC development, through integration and scaling, to continuous modernization of your IoT predictive maintenance systems. We can help you with:

- Firmware and embedded development to ensure reliable communication between hardware and software components.

- Connected device engineering and wearable app development for connected systems and mobility across the business site.

- Integration of sensors, connected devices, and solutions with ERP, CRM, MES, or cloud platforms for seamless data flow.

- AI, ML, and data analytics services to transform raw sensor data into actionable insights.

- Secure and scalable platform development to ensure your system scales as operations expand.

- Continuous monitoring and modernization to maintain accuracy and efficiency with ongoing updates, retraining, and system enhancements.

- Industry-specific customization to optimize IoT-based predictive maintenance for manufacturing, automotive, healthcare, logistics, and other industries, while ensuring regulatory compliance and sustainability goals.

Ready to transform your maintenance strategy? Partner with N-iX to implement predictive maintenance solutions that keep your operations running smoothly and securely.

Sources:

- The Internet of Things: Catching up to an accelerating opportunity | McKinsey&Company

- Eseye 2024 State of IoT Adoption | Eseye

- IoT and Telecom Predictions for 2025 and Beyond: The Year of Risers and Fallers in IoT| Eseye

Have a question?

Speak to an expert