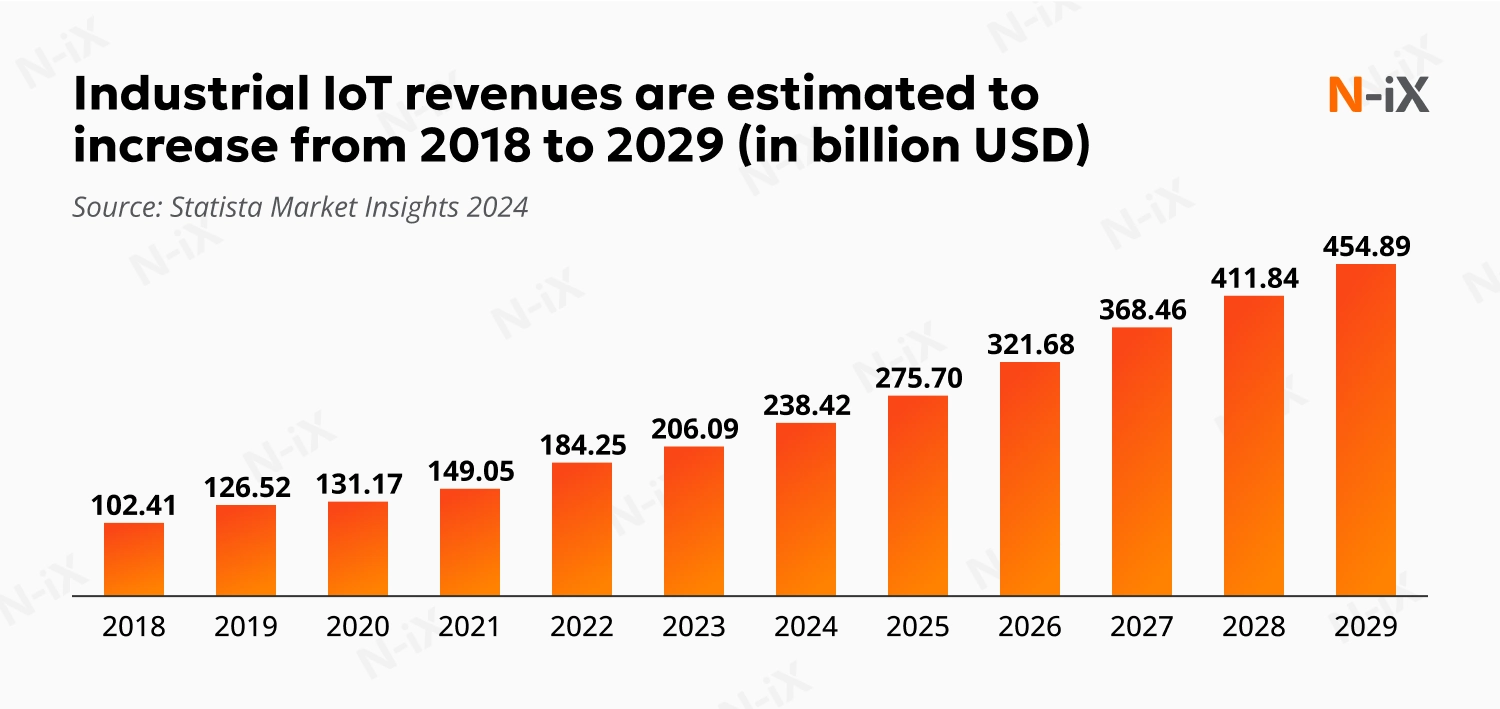

Industrial Internet of Things (IIoT) drives measurable results across sectors, with market revenue growth projected to reach $454.89B by 2029, according to Statista's Industrial IoT: Market Data and Analysis report [1]. And that's no wonder.

The number of industrial Internet of Things (IoT) devices is increasing annually. According to Statista's report, the total global number is expected to grow from 5.45B in 2025 to 9.84B in 2028. This adoption is related to the value that IoT technology holds in the industrial setting and the expansion of industrial IoT use cases that span beyond manufacturing, management, and logistics. The article examines the importance of adopting IoT and explores its applications for enhancing operations. Let's dive in.

How can adopting industrial IoT benefit your enterprise?

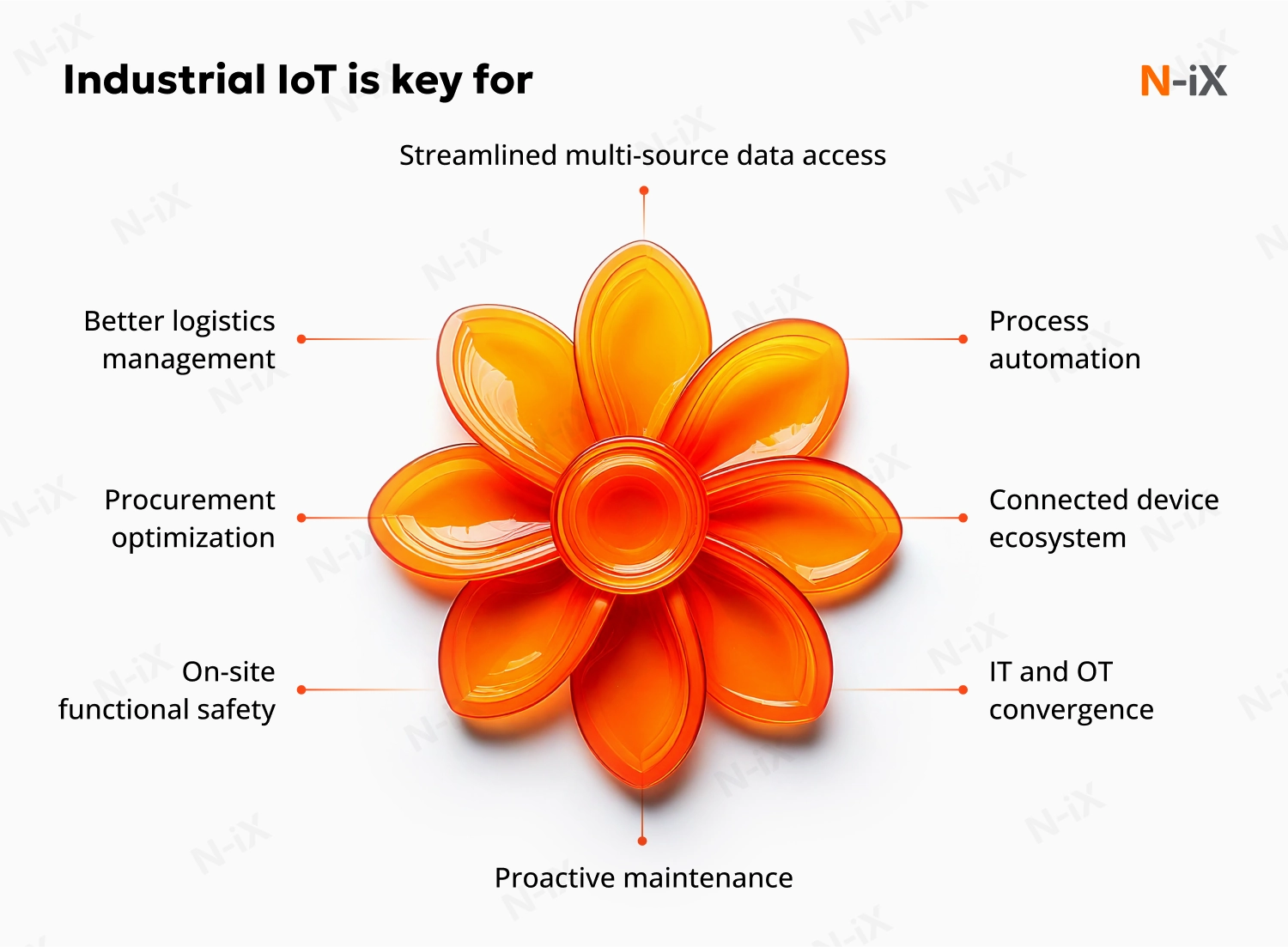

Industrial IoT connects devices, sensors, applications, and networking equipment that collect and analyze operational data. Adopting these technologies in the industrial setting can provide a starting point and enhance numerous processes and workflows. Here are a few of them.

- IoT allows access to data from machinery and the environment, providing actionable insights for better decision-making.

- It enables process automation, streamlines workflows, increases productivity, and ensures operational consistency.

- It allows the creation of a connected device ecosystem by introducing seamless communication between devices, sensors, and systems.

- It facilitates the conversion of IT and OT departments, fostering better data integration and enterprise-wide visibility.

- It enables predictive maintenance, helping businesses intervene before failure occurs, thereby reducing downtime and extending asset lifespan.

- It helps achieve functional safety on-site by continuously monitoring machines and environments for potential hazards.

- It enables more accurate procurement, streamlines inventory management and resource tracking, and reduces waste and excess stock.

- It helps improve logistics by providing real-time tracking and monitoring of goods and assets.

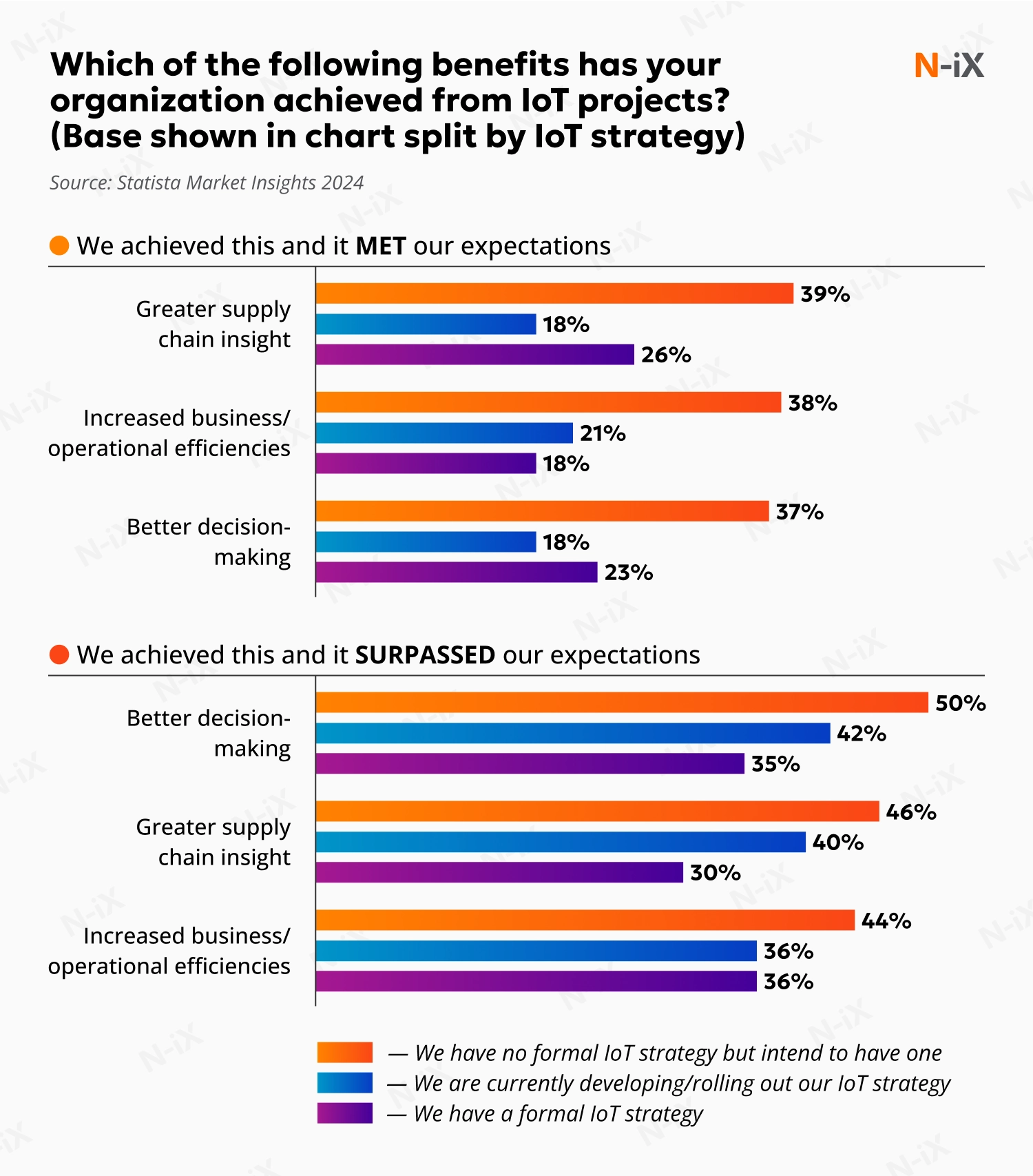

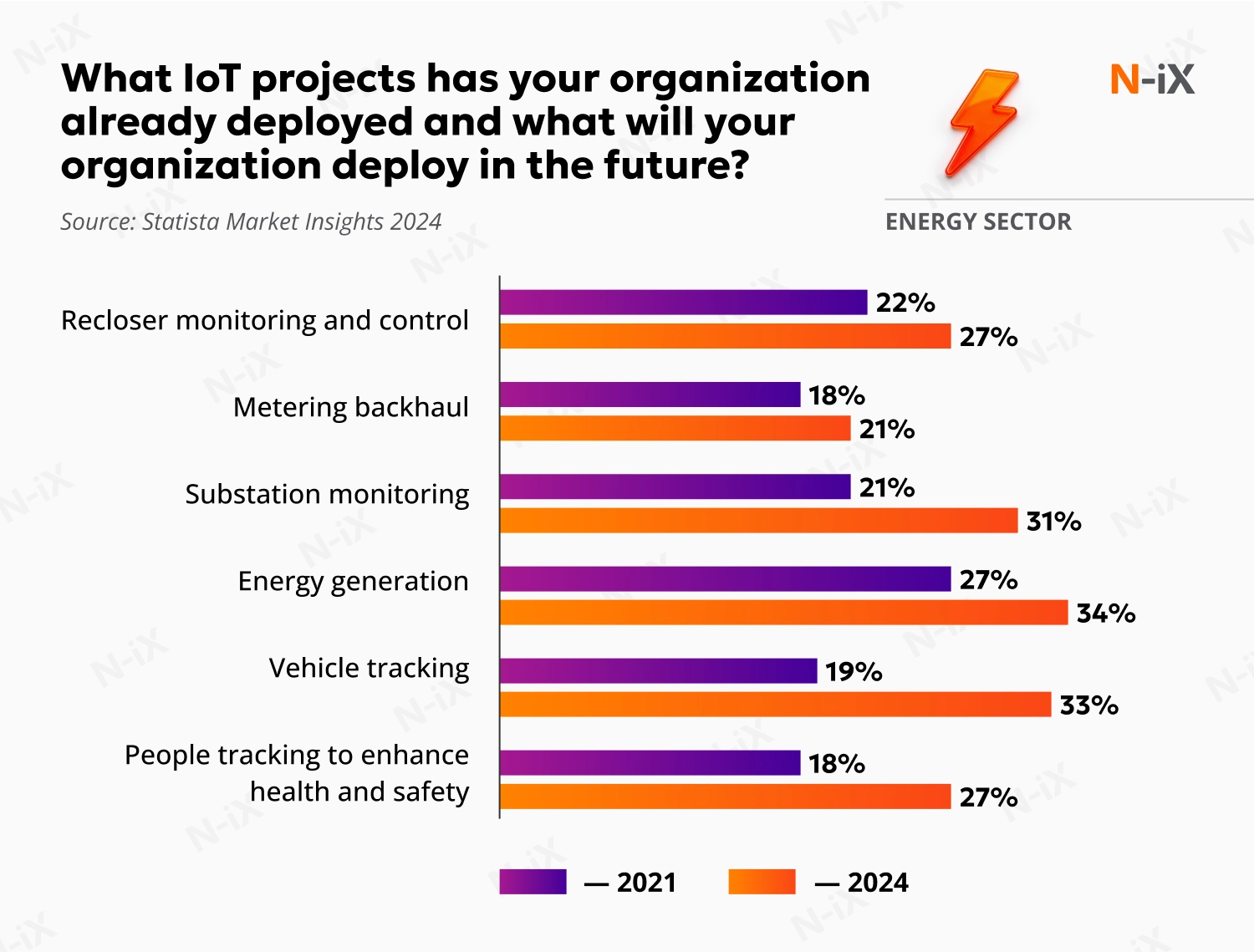

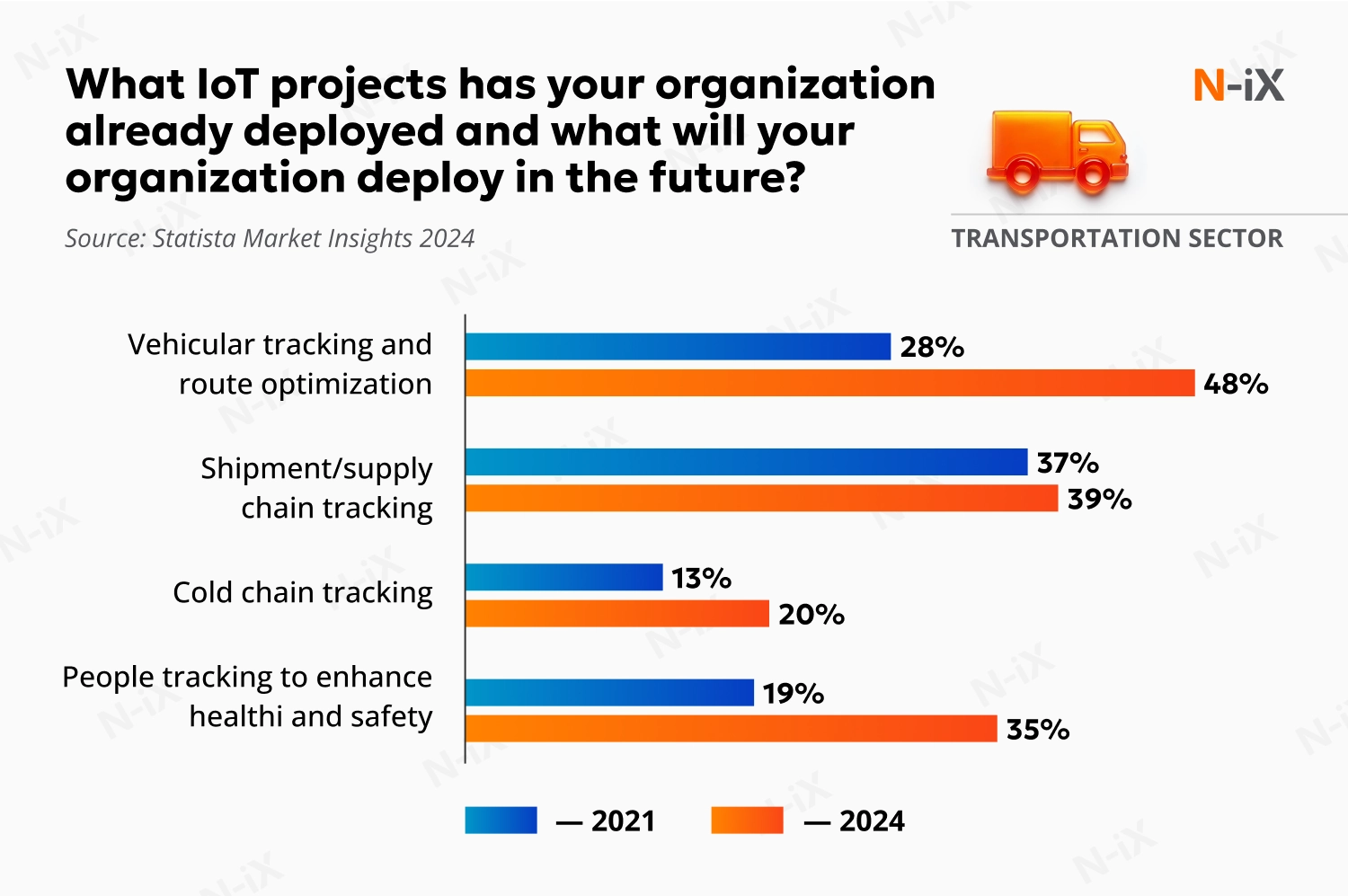

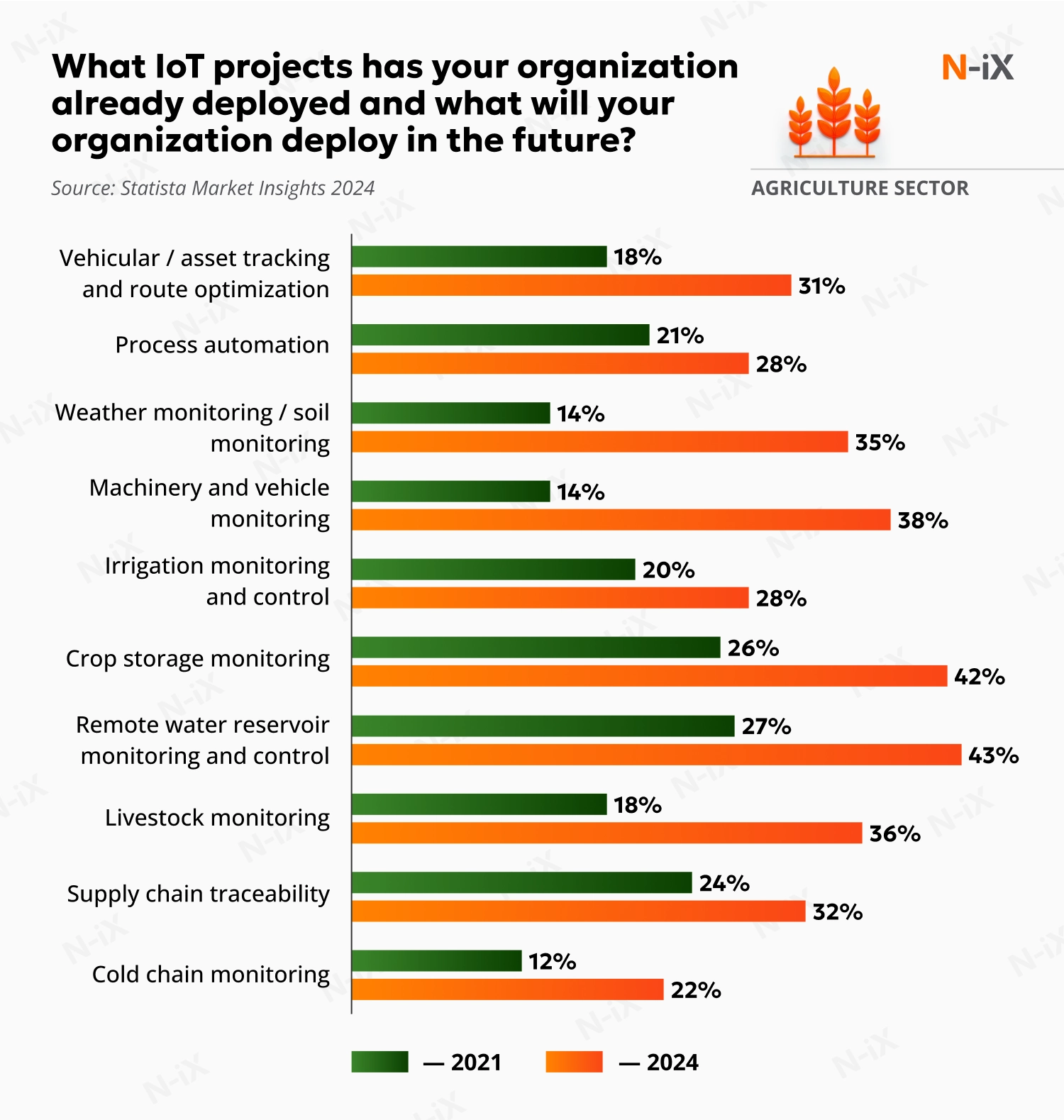

According to the "State of Industrial IoT in 2024" report by Viasat, businesses have already measured the benefits of industrial IoT use cases [2]. They surveyed 600 businesses from the agriculture, energy, mining, transport, and utilities industries in various regions. The researchers found that businesses reported greater supply chain insight, increased business and operational efficiencies, and better decision-making as a result of their IoT projects, with the rate of improvement depending on the maturity of their IoT strategy.

While there are numerous industrial Internet of Things use cases, businesses should assess which one would be the most beneficial to invest in. Let's review a few of the most popular ones.

Explore key IIoT trends for industrial manufacturers for 2026

Top industrial IoT use cases to drive data-led efficiency enterprise-wide

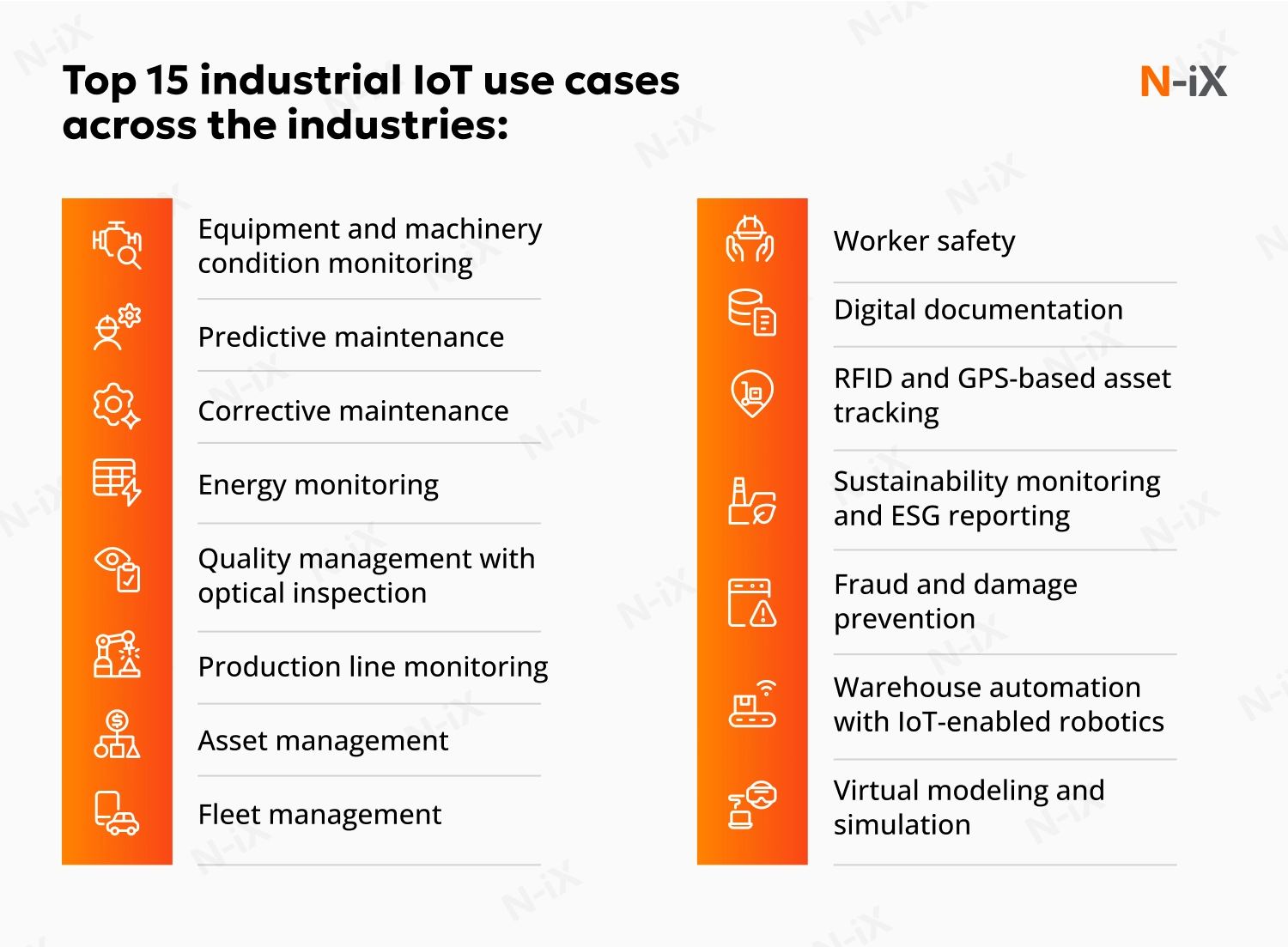

From predictive maintenance to ESG reporting and resource management, use cases of IIoT vary, depending on the industry and application. Here are the top 15 ones to consider for your enterprise.

Equipment and machinery condition monitoring

Condition monitoring is one of the IIoT use cases involving real-time tracking of machines and plants to detect any irregularities that may lead to downtime. By leveraging IoT sensors, businesses can proactively monitor machine health, resulting in reduced unplanned downtime and improved maintenance strategies that enhance overall operational efficiency.

Key industries for this use case: Manufacturing, energy, mining.

Read further: IoT in smart manufacturing: Insights for enterprises

Harness AIoT for smarter operations—get the guide to industry use cases!

Success!

Predictive maintenance

Predictive maintenance uses data-driven analytics to anticipate equipment failure before it happens, helping companies take proactive measures. By predicting potential failures, organizations can schedule maintenance more effectively, reducing downtime and increasing the longevity of equipment while optimizing costs.

Key industries for this use case: Automotive, manufacturing, aerospace.

Corrective maintenance

One of the most powerful use cases of the industrial Internet of Things is corrective maintenance. It involves quick responses to unexpected machine failures, ensuring minimal downtime and less disruption to production schedules. By utilizing IoT sensors and real-time monitoring, businesses can respond quickly to failures, reducing the duration of repairs and minimizing production disruptions.

Key industries for this use case: Manufacturing, oil and gas, chemical processing, and other industries with potentially hazardous conditions

If a plant has a digital nervous system, IIoT would be the neural wiring that enables scattered parts and machines to feel, think, and act as one agile organism.

Mykhaylo Kohut

Solution Architect, Embedded & IoT Practice

Energy monitoring

Energy monitoring helps businesses track energy consumption in real-time, providing insights into inefficiencies and enabling them to reduce energy costs. With IoT-powered energy monitoring systems, companies can make data-driven decisions to optimize energy use, ensuring cost savings and contributing to sustainability goals.

Key industries for this use case: Logistics, manufacturing, agriculture, automotive, transportation.

Quality management with optical inspection

Quality management is one of the most popular industrial IoT use cases. IoT-driven quality management systems with automated optical inspection (AOI) ensure consistent product quality by monitoring production processes and identifying potential errors early. AOI applications include object identification, completeness checks, defect detection, and component measurement.

In printed circuit board (PCB) manufacturing, for example, AOI systems detect near-microscopic flaws humans miss, reducing false alarms through trained AI algorithms. With the ability to detect deviations in real time, businesses can reduce the rate of defects, improve product consistency, and ensure compliance with industry standards.

Key industries for this use case: Automotive, manufacturing, electronics, pharmaceuticals.

Explore the topic: AI agents in industrial IoT: Turning data into intelligent action

Production line monitoring

Real-time production monitoring offers instant visibility into manufacturing processes, eliminating the need for manual data entry. These systems connect directly to machine controls through edge devices that process and stream data securely to cloud platforms. Color-coded IoT data visualization tiles display machine status and production efficiency, allowing operators to identify issues immediately and meet production goals. Teams can visualize machine utilization by hour, shift, day, or month to uncover hidden capacity across operations.

Key industries for this use case: Manufacturing, pharmaceuticals, food and beverage, automotive.

Asset management

Asset management is one of the worth-mentioned industrial IoT use cases. It involves optimizing the operation, maintenance, and management of physical assets using IoT solutions. The latter helps businesses track asset performance, schedule maintenance, and extend the lifecycle of critical equipment.

For example, turbines with IoT sensors on wind farms continuously stream data on blade vibration, gearbox temperature, and power output to a cloud-based asset management platform. The system's analytics engine flags wear far in advance, automatically scheduling field maintenance works to prevent the turbine from unplanned outage.

Key industries for this use case: Manufacturing, utilities, logistics, supply chain, warehousing, retail.

Fleet management

Fleet management solutions in IoT help optimize vehicle fleets by monitoring vehicle health, tracking routes, and ensuring the efficient use of resources. With real-time data on vehicle performance and fuel consumption, businesses can reduce operating costs, improve route planning, and enhance driver safety, ensuring smooth fleet operations.

A case in point, N-iX helped a client build an OEM-grade Linux connectivity gateway that pipes live GPS, CAN bus, and sensor data from every truck into a Google Cloud IoT platform. We complemented it with an Android app for rugged tablets that keeps drivers informed on the move. This solution enables clients to gain real-time visibility into speed, fuel consumption, and engine health through predictive maintenance alerts.

Key industries for this use case: Transportation, logistics, delivery services, car rentals.

Learn about other applications of IoT in the automotive industry

Worker safety

IoT solutions for worker safety encompass technologies that monitor environmental conditions and track employees' health in real time. From detecting hazardous gases to streamlining emergency communication, IoT systems help ensure maximum safety while minimizing workplace accidents and ensuring compliance with safety regulations.

For example, one of N-iX's IIoT case studies in healthcare features firmware solution development for the manufacturer of air decontamination and filtration devices. We helped our client upgrade the controlling PCB to Raspberry Pi 3 A+ and set up Linux OS to create a versatile and cost-effective platform. Additionally, we developed a Flutter-based cross-platform app for managing remote decontamination systems. As a result, the solution can prevent the spread of airborne infections and enable remote condition monitoring, ensuring the safety of hospital staff.

Key industries for this use case: Construction, mining, manufacturing, waste management, healthcare.

Digital documentation

Digital documentation transforms traditional paper-based processes into streamlined, paperless workflows. This not only reduces administrative workload but also enhances the accuracy of records, improves compliance, and facilitates faster decision-making.

This is one of the industrial IoT use cases that can be applied in various industries, particularly those with strict quality management and audit practices. In a medical device factory, for instance, every production cell can be equipped with rugged tablets that let technicians fill, sign, and upload quality inspection forms the moment each part is completed. The paperless workflow eliminates duplicate data entry, provides auditors with instant traceability, and reduces compliance report preparation time.

Key industries for this use case: Healthcare, manufacturing, logistics.

RFID and GPS-based asset tracking

Asset tracking involves monitoring the location and condition of valuable goods in real-time, ensuring optimized logistics and increased operational efficiency. RFID and GBS-based IoT solutions using these technologies provide businesses with complete visibility into the real-time location and status of assets, improving supply chain management, reducing theft, optimizing routes, and ensuring the timely delivery of goods.

Key industries for this use case: Logistics, healthcare, retail, supply chain, warehousing.

Deep dive into how IoT in the retail industry helps businesses evolve

Sustainability monitoring and ESG reporting

IoT solutions for sustainability help businesses monitor and reduce their environmental impact by optimizing resource consumption and tracking emissions. IoT-enabled monitoring systems allow businesses to track energy use, water consumption, and emissions in real-time. This step is crucial for achieving local Environmental, Social, and Governance (ESG) regulatory compliance and enhancing environmental performance.

Key industries for this use case: Energy, manufacturing, transportation, logistics, agriculture, and other sectors where companies are required to report their sustainability activities.

Fraud and damage prevention

Fraud and damage prevention is one of the industrial IoT use cases where IoT technologies detect and mitigate risks early, helping businesses safeguard their assets. By implementing IoT solutions that monitor operations in real-time, businesses can identify suspicious activities and take corrective actions to minimize potential losses.

Key industries for this use case: Logistics, retail, luxury goods.

Warehouse automation with IoT-enabled robotics

Warehouses represent prime territory for implementing IoT in the industrial sector. Automated robotics systems handle inventory management, equipment monitoring, and workflow optimization without human intervention.

For example, warehouse drones equipped with RFID scanners or barcode readers capture real-time inventory data as they fly through facilities. These aerial robots identify misplaced stock and provide high-resolution images showing warehouse traffic patterns and storage utilization.

Key industries for this use case: Logistics, retail, manufacturing.

Learn how you can use IoT in inventory management and explore top tips to make it work

Virtual modeling and simulation

One of the top industrial IoT use cases is the creation of virtual models and digital twins of the physical assets, systems, or entire processes for real-time monitoring and analysis. By collecting data from IoT sensors and systems, companies can simulate real-world scenarios, optimize performance, and predict potential failures.

For example, in manufacturing, a digital twin of a production line allows engineers to model different production scenarios and monitor equipment health in real-time, adjusting processes before issues arise. This simulation-driven approach improves efficiency, reduces downtime, and ensures that maintenance is performed proactively rather than reactively.

Key industries for this use case: Manufacturing, automotive, aerospace, energy.

These use cases are the most popular throughout the industries. However, each business may need a custom use of industrial IoT technology for their operations. N-iX offers end-to-end IoT development services to help you develop and tailor industrial IoT solutions that would correlate with your current technology maturity and future transformation strategy. Here's what makes us qualified to work on your IIoT use case.

Haven't found the industrial IoT use cases you need? Develop a custom one with N-iX

Successful industrial IoT implementation requires a trusted technology partner. N-iX delivers comprehensive IoT solutions development services that drive innovation and efficiency across diverse industries. With our tech expertise spanning IoT development, IoT security services, embedded development, firmware development, wearable device and app development, connected device development, and more, we can help you build a reliable industrial IoT ecosystem. And we offer more than that.

- We provide end-to-end hardware and software development services, such as consulting, product discovery, design, development, testing, and support;

- We currently employ over 2,400 experts who have experience working with medium-sized businesses and global enterprises, including Fortune 500 companies;

- N-iX has a portfolio of over 60 completed projects with provided embedded, firmware, and IoT connectivity expertise;

- Our IoT engineers developed solutions for the use cases for clients from manufacturing, logistics and supply chain, retail, telecom, automotive, healthcare, energy and utilities, and agritech industries;

- N-iX has established tech partnerships with semiconductor producers (Nordic Semiconductor), microcontroller manufacturers (Raspberry Pi), network connectivity providers (Wirepas), and major cloud providers (AWS, GCP, Microsoft Azure);

- We have a dedicated IoT and embedded development lab for prototyping, automated testing, and iterative development;

- With offices in Malta, Poland, Bulgaria, Colombia, Ukraine, Sweden, the USA, the UK, and India, we help businesses outsource their industrial IoT projects;

- We offer software engineering, cloud solutions, data analytics, enterprise platform and RPA, AI, ML, MLOps, cybersecurity, computer vision, and other services to power your industrial IoT solutions with modern capabilities.

IIoT implementation represents a strategic priority, not a future consideration. With the right expertise and technology partnerships, organizations can adopt these proven solutions while minimizing operational disruptions. We help you build smarter operations that deliver measurable results today while positioning your business for continued success.

Sources:

- Industrial IoT: Market Data and Analysis report 2024 | Statista

- The State of Industrial IoT in 2024 | Viasat

Have a question?

Speak to an expert