Today, manufacturing downtime costs industrial facilities more than it did a few years ago. According to Siemens's The Cost of Downtime 2024 report , a lost hour at an automotive plant costs up to $2.3M, and at a fast-moving consumer goods (FMCG) plant, up to $36,000 [1]. Over a year, the world's 500 largest enterprises lose about 11% of their revenue, totaling $1.4T. A significant share of these costs can be prevented through the adoption of the Internet of Things (IoT) and IoT-powered predictive maintenance.

IoT devices minimize downtime in manufacturing plants through advanced, multifaceted approaches that extend far beyond traditional maintenance predictions. This article explores how companies can use technology to reduce lost hours in a manufacturing plant, and how N-iX can help you build IoT solutions and develop manufacturing software to reduce downtime costs. First, let's explore the manufacturing challenges that cause downtime.

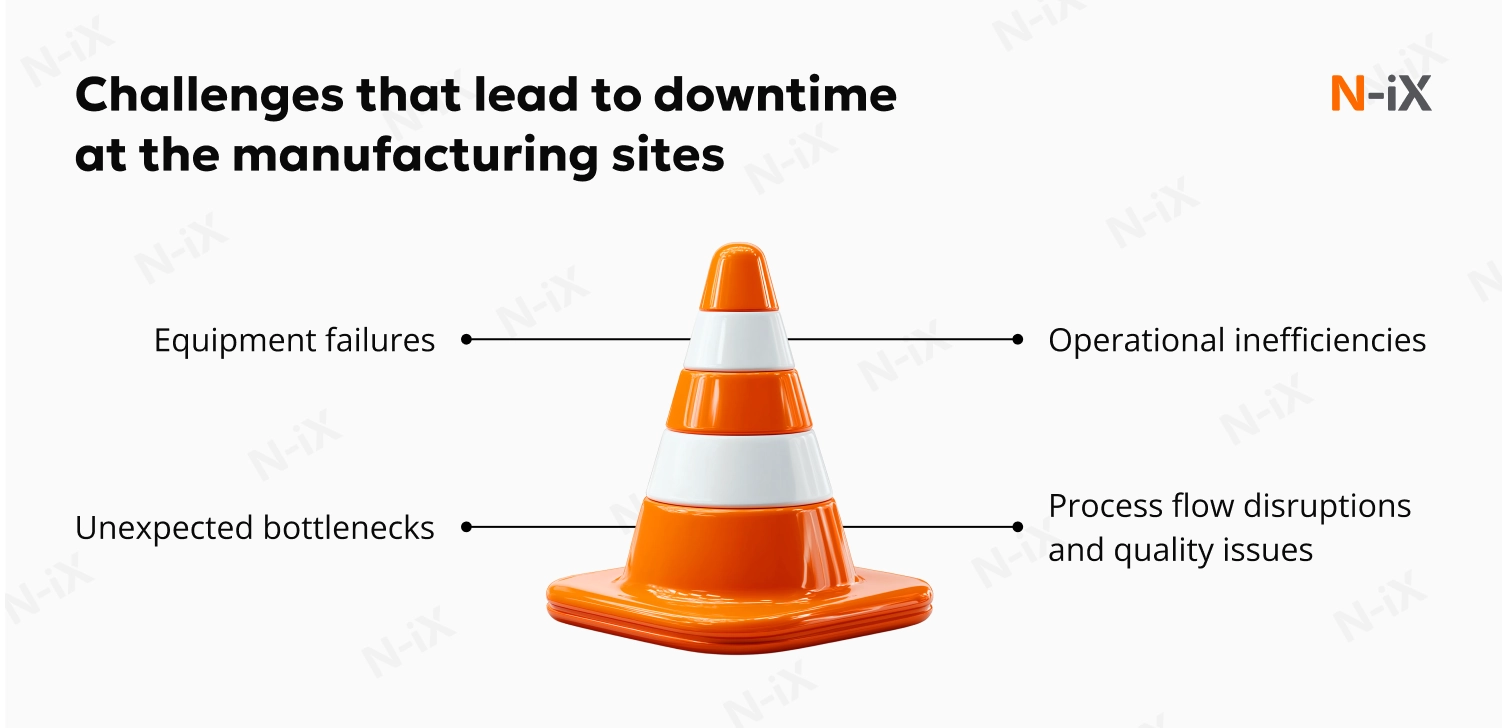

Challenges that lead to downtime at the manufacturing sites

Manufacturing downtime rarely has a single cause. In most plants, it results from a combination of equipment-related issues, process inefficiencies, and human or organizational factors that compound over time. It's especially true in asset-intensive industries such as automotive, metals, and process manufacturing. Based on real-world manufacturing operations, the most common downtime drivers include the following:

Equipment failures

According to the Value of Reliability: ABB Survey Report 2023, 69% of surveyed manufacturing businesses experience unplanned equipment downtime at least once a month, and 8% face it daily [2]. Mechanical wear, lubrication degradation, overheating, sensor drift, and misalignment are among the most frequent failure modes. In many industrial environments, equipment-related issues account for the majority of unplanned downtime, especially when early warning signals go undetected.

Operational inefficiencies

Manual interventions, fragmented data across systems, and a lack of real-time visibility slow down decision-making. Small inefficiencies, such as delayed changeovers or improper machine settings, often accumulate into significant production losses.

Unexpected bottlenecks

Material shortages, uneven cycle times, and constrained workstations disrupt production flow. These bottlenecks are often caused not by a single failure but by poor synchronization between machines, materials, and labor.

Process flow disruptions and quality issues

Variations in process parameters, inconsistent quality checks, and rework caused by machine drift or human error can halt production lines. Quality-related downtime is particularly costly because it affects both throughput and output consistency.

These issues not only lead to costly downtime but also decrease unit performance, affecting both the bottom line and overall productivity. However, IoT solutions can tackle these challenges. Let's review how.

Explore the topic: IoT in smart manufacturing: Insights for enterprises

IoT devices minimize downtime through integration of OT and IT

IoT devices enable IT/OT convergence, which integrates information technology (IT) systems with operational technology (OT) in manufacturing environments. By connecting machine sensors and digital systems, such as cloud platforms and enterprise software, they enable continuous, real-time data exchange throughout the entire production process.

This integration enables automated decision-making that proactively minimizes downtime. For example, sensors can detect operational anomalies (e.g., temperature fluctuations) and immediately trigger corrective actions, such as adjusting machine settings, either automatically or through operator-approved workflows.

Additionally, connected devices provide real-time insights that allow manufacturers to identify possible issues before they cause major disruptions, shifting from reactive to predictive maintenance.

Ultimately, IoT-based tools create a more responsive manufacturing environment, where instant actions and data-driven decisions reduce unplanned downtime and improve overall production efficiency.

Make the most of predictive maintenance in automotive industry

IoT wearables empower operators to minimize downtime through real-time decision-making

IoT wearables and wearable applications are enhancing how operators manage equipment and safety in manufacturing environments. They provide employees with real-time, contextual insights that enable faster, more informed decision-making to minimize downtime.

These devices, such as smartwatches and connected safety equipment, and apps connected to them, provide operators with instant alerts about potential issues with equipment or safety conditions, ensuring problems are addressed before they lead to costly production stoppages.

IoT-powered wearables help minimize downtime by:

- Sending anomaly notifications that allow operators to detect and resolve issues before they disrupt operations;

- Distributing safety alerts to prevent accidents and human-error downtime, which could otherwise halt production;

- Enabling faster responses to critical maintenance needs, reducing delays caused by traditional notification methods.

By delivering real-time data directly to operators, IoT wearables help them act quickly, reducing response times and preventing downtime that can result from missed cues or delayed interventions.

IoT for equipment monitoring to prevent unplanned downtime

IoT-based equipment monitoring enables manufacturing plants to continuously track the real operating condition of machines, rather than relying on periodic inspections or fixed thresholds. By collecting live data from sensors embedded in or attached to equipment, manufacturers gain full visibility into how assets perform under real production conditions.

IoT sensors monitor critical parameters such as temperature, vibration, pressure, load, and energy consumption. Changes in these signals often indicate early signs of wear, misalignment, lubrication issues, or process instability long before a failure occurs.

IoT-powered equipment monitoring helps reduce downtime by:

- Detecting abnormal temperature, vibration, or pressure patterns that signal emerging mechanical issues;

- Correlating data from multiple sensors to distinguish real risks from normal operating variation;

- Triggering alerts or automated actions when equipment behavior deviates from safe operating ranges.

By providing a continuous, data-driven view of machine health, IoT equipment monitoring allows maintenance and operations teams to intervene early, reducing unexpected breakdowns and preventing downtime before it impacts production.

IoT for automated alerts and diagnostics to reduce downtime

IoT-based automated alerts and diagnostics go beyond simple threshold warnings by combining real-time sensor data with contextual analysis to identify what is failing and why. When abnormal behavior is detected, IoT platforms correlate sensor readings, machine states, and event sequences to trigger precise alerts across operator dashboards, mobile devices, and maintenance systems.

Instead of generic alarms, automated diagnostics associate anomalies with specific components, error codes, or operating conditions, when integrated with PLCs, control systems, and asset models. It allows teams to quickly understand the root cause of an issue. Alerts can also include recommended actions or escalation paths, reducing the time spent on manual investigation.

Using IoT-powered alerts and diagnostics as a part of a downtime reduction strategy helps:

- Detect and classify anomalies using correlated sensor data and machine events;

- Pinpoint probable root causes rather than issuing isolated alerts;

- Deliver actionable notifications to the right teams and systems in real time.

By accelerating issue identification and diagnosis, IoT-driven alerts and diagnostics shorten response times and prevent minor faults from escalating into extended production downtime.

IoT for predictive maintenance to reduce downtime

IoT-powered predictive maintenance helps manufacturing teams move from reacting to breakdowns to preventing them by predicting failures before they stop production. It uses continuous equipment monitoring data to spot early degradation signals and prioritize maintenance actions based on actual asset condition.

These systems combine IoT sensor streams, such as vibration, temperature, pressure, and energy consumption, with machine learning algorithms that detect trends over time. Instead of relying on static thresholds, the algorithms learn what “normal” looks like for each asset and flag deviations that typically precede failure, often with an estimate of remaining useful life for key components.

IoT-based predictive maintenance helps minimize downtime by:

- Identifying failure patterns early by analyzing trends in critical equipment parameters over time;

- Estimating remaining equipment lifespan to plan maintenance windows before a breakdown occurs;

- Replacing reactive repairs with scheduled interventions that reduce unplanned stoppages.

By turning raw sensor data into failure forecasts and maintenance timing recommendations, IoT-based predictive maintenance reduces unexpected equipment failures and helps keep production running predictably.

IoT for better process flow monitoring and bottleneck prevention

Process bottlenecks are a significant contributor to downtime, often causing more disruptions than equipment failures. IoT solutions play a critical role in minimizing downtime by continuously monitoring the entire production flow, identifying inefficiencies, and preventing bottlenecks before they escalate into costly stoppages.

By using RFID tags and vision systems, IoT devices provide real-time monitoring of material movement across the production line. This ensures that components reach workstations precisely when needed, avoiding delays caused by material shortages or logistical issues.

How IoT helps minimize downtime through real-time tracking:

- RFID and vision systems track material flow in real-time, providing full visibility into production.

- Early detection of potential slowdowns or bottlenecks enables proactive measures.

- Automated alerts notify operators of potential blockages or inefficiencies, enabling them to act before disruptions impact production.

With IoT-connected devices, manufacturers can take proactive steps to prevent bottlenecks, ensuring a smooth production flow and significantly reducing downtime from material-handling delays.

IoT for workflow inefficiency detection and automated corrections

Workflow inefficiencies can often lead to downtime if not addressed promptly. IoT networks continuously monitor and analyze entire production flows, detecting even subtle workflow variations that could indicate inefficiencies or potential disruptions. By leveraging real-time data, IoT solutions can autonomously trigger automated corrections that ensure smooth operations and minimize downtime.

Example of automated process corrections to minimize downtime:

- PLCs (Programmable Logic Controllers) receive data from connected sensors and automatically adjust production speeds to maintain optimal flow, preventing bottlenecks.

- Temperature variations detected by IoT sensors can automatically trigger cooling systems to adjust and prevent overheating, ensuring that machines continue running without interruption.

- Flow optimization is achieved through IoT-enabled systems that automatically adjust material-handling speeds or process sequencing to avoid delays without requiring manual intervention.

These automated adjustments ensure that manufacturing environments remain efficient and responsive, addressing workflow inefficiencies in real time before they affect production. As a result, downtime is minimized by maintaining continuous, uninterrupted operations.

Using historical IoT data for system redesign to minimize downtime

Historical IoT data is a powerful tool for identifying long-term inefficiencies and driving system redesigns to minimize downtime. By continuously collecting data over months or years, IoT systems provide insights into recurring patterns and performance trends, enabling manufacturers to make informed, data-driven decisions to optimize production processes and sustain uptime.

How historical IoT data helps minimize downtime:

- Identification of recurring equipment issues. By analyzing long-term data, manufacturers can spot recurring equipment failures, enabling them to redesign systems or implement preemptive maintenance schedules to prevent future downtime.

- Improved resource utilization. Historical data reveals patterns in how resources (machines, materials, labor) are used, helping manufacturers streamline workflows and improve overall efficiency, reducing downtime caused by misallocated resources.

- System redesigns based on real-world performance. Rather than relying on theoretical models, manufacturers can use real-time data collected over time to redesign systems that address actual production issues, ensuring higher reliability and lower downtime.

This continuous feedback loop of real-time data and iterative improvements leads to long-term optimization, in which manufacturing processes become more efficient and robust, effectively reducing downtime.

Alone, however, IoT can't do much. That's why it's usually paired with other technologies that amplify each other's capabilities in manufacturing settings. Let's review how some combinations can reduce downtime.

Learn about the top IIoT trends shaping the future of manufacturing in 2026

Integration of IoT and other technologies to cut downtime

Integrating IoT with other technologies is beneficial for reducing downtime in manufacturing. By connecting real-time data with smart analytics and automated systems, businesses can quickly spot issues and address them before they cause any delays. Let's review some of the combinations that help companies keep operations running smoothly and avoid costly disruptions.

IoT as an edge computing enabler for immediate equipment response

In modern manufacturing, edge computing plays a critical role in minimizing downtime, particularly when integrated with IoT. Unlike traditional systems that rely on remote cloud servers, edge computing processes data locally at the equipment site, enabling faster response times and reducing the risk of downtime.

When sensors are connected to edge devices, data is analyzed at the point of collection. It helps detect and solve issues such as temperature spikes, vibration anomalies, or performance discrepancies in milliseconds, without waiting for cloud-based data processing. For example, a temperature sensor could trigger the cooling system immediately upon detecting abnormal heat through local control logic or PLC integration, preventing overheating and ensuring uninterrupted operation.

Key benefits of edge computing and IoT in minimizing downtime:

- Real-time data analysis directly at the equipment level, eliminating delays;

- Immediate automated responses to critical conditions, ensuring proactive issue resolution;

- Seamless operation even during network disruptions, as data is processed locally.

By combining IoT-enabled sensors with edge computing, manufacturers can respond to potential problems instantly, before they escalate into major disruptions, leading to a significant reduction in unplanned downtime.

AI-powered process optimization: A key way IoT devices minimize downtime

When combined with IoT, AI becomes a powerful tool for minimizing downtime in manufacturing. IoT sensors generate real-time data from the factory floor, and AI algorithms analyze it to optimize processes and identify inefficiencies that might go unnoticed by human operators. This synergy between IoT and AI is a cornerstone of AIoT applications in industrial settings, where smarter systems drive productivity and minimize disruptions.

Unlike traditional systems that react to problems, AI-powered IoT systems can predict and autonomously adjust workflows in real-time, minimizing disruptions before they affect production. For example, sensors might detect an anomaly in machine behavior, and AI will immediately analyze the data to adjust settings or trigger maintenance actions, preventing downtime from escalating.

How IoT and AI minimize downtime:

- Pattern recognition. AI identifies inefficiencies and trends across data from multiple IoT sources, enabling continuous process improvements.

- Real-time adjustments. AI leverages insights from IoT data to adjust operations in real time, ensuring optimal performance and reducing production delays.

- Proactive decision-making. AI-powered insights enable preemptive actions to address potential failures, saving both time and costs.

By integrating AI with IoT, manufacturers can enhance operational efficiency, detect inefficiencies early, and proactively manage processes, significantly reducing downtime and optimizing uptime.

More on the topic: AI in predictive maintenance: A guide to proactive asset management for leaders

IoT sensors and Machine Learning for adaptive production lines to reduce downtime

Integrating Machine Learning (ML) with IoT sensors allows manufacturing systems to become adaptive, automatically adjusting to changing conditions. This combination enables real-time learning from data generated by IoT devices, ensuring that production lines can quickly respond to unexpected changes, such as new product lines, seasonal demand fluctuations, or equipment variances, without causing downtime.

How ML and IoT minimize downtime:

- Real-time learning. ML algorithms analyze continuous data streams from IoT sensors, enabling the system to automatically evolve and optimize production conditions.

- Self-adjusting production lines. The system can adjust speed, equipment settings, and even resource allocation in real time, ensuring optimal performance at all times.

- Enhanced resilience. By continuously learning from operational data, the system becomes more resilient to disruptions, anticipating challenges such as equipment wear or process inefficiencies and addressing them before they cause downtime.

With ML and IoT, manufacturers can create dynamic, self-optimizing production lines that can handle unplanned changes without halting operations. This helps design more efficient production cycles and significantly reduces downtime.

IoT and augmented reality (AR) interfaces for on-the-spot guidance

AR interfaces are revolutionizing how operators interact with equipment by providing real-time diagnostics and maintenance instructions directly on their IoT-enabled AR glasses or tablets. This instant access to information allows operators to troubleshoot and resolve issues independently, without waiting for expert intervention, thereby significantly minimizing downtime during maintenance.

How AR enhances decision-making and minimizes downtime:

- Visual overlays provide step-by-step guidance, helping operators perform maintenance tasks efficiently and accurately.

- Remote expertise via AR enables operators to access expert support and instructions virtually, reducing the need for on-site specialists and speeding problem resolution.

- Immediate problem resolution increases production efficiency by addressing issues quickly and preventing unnecessary delays.

By integrating IoT devices with AR technology, operators can resolve issues swiftly, reduce reliance on external expertise, and ensure continuous operations, ultimately minimizing downtime.

While IoT-powered sensors may be key to minimizing downtime in manufacturing plants, they are only effective if designed, developed, and implemented correctly. As one of the IoT software development companies with over 23 years of experience in end-to-end software development, we help clients to adopt IoT and integrate it with other technologies. Here's how we can help your business decrease downtime with our IoT expertise.

N-iX's IoT expertise for manufacturing sites

With a track record in predictive maintenance, data analytics, and IoT development, we empower businesses to streamline processes, enhance asset management, and improve operational efficiency.

N-iX has already developed a customizable predictive maintenance solution that can be tailored to various industries, including manufacturing, telecom, logistics, automotive, oil and gas, and more. Our solution leverages embedded and firmware development, advanced data analytics, AI, ML, AR, and more to help businesses reduce costs, improve efficiency, and enhance safety by predicting equipment failures before they happen. By utilizing real-time data, we empower companies to refine their maintenance practices, make more informed decisions, and ultimately minimize downtime while extending the lifespan of their assets.

Our expertise spans across manufacturing, logistics and supply chain, retail, telecom, automotive, healthcare, energy and utilities, and agritech industries, enabling us to deliver custom IoT solutions that drive value for manufacturers. With solutions that integrate seamlessly with cloud platforms, AI-powered systems, and edge computing, we ensure continuous operations and optimized workflows.

Our IoT services help clients build manufacturing solutions for:

- IoT-based predictive maintenance. Minimize unplanned downtime with data-driven maintenance strategies.

- Real-time monitoring. Monitor equipment performance and operational metrics for instant insights.

- AI-powered process optimization. Use machine learning and AI to optimize workflows and reduce inefficiencies.

- Edge data processing. Enable fast, local decision-making at the device level for immediate action.

- Data analytics & IoT data visualization. Turn IoT data into actionable insights with advanced analytics and intuitive dashboards.

- IoT system integration. Seamlessly connect IoT devices with existing enterprise systems (ERP, CMMS, etc.).

- Remote monitoring and diagnostics. Empower remote teams with the ability to monitor and troubleshoot equipment issues from anywhere.

- Wearable app development. Build IoT-enabled wearable applications that deliver real-time alerts, safety notifications, and operational insights to plant personnel.

- Connected device engineering. Design, develop, and integrate industrial IoT sensors, gateways, and embedded software tailored to manufacturing environments.

- IoT security services. Protect connected devices, data flows, and IoT platforms with security-by-design, threat modeling, and compliance-ready architectures.

We understand that no two manufacturing plants are alike. That’s why we help you build custom IoT solutions that meet your specific needs. Whether you’re dealing with complex legacy systems, diverse production lines, or unique operational goals, we ensure seamless integration and deliver solutions that maximize uptime and minimize downtime across your entire operation.

Partnering with N-iX means working with a trusted IoT services provider, committed to delivering solutions that enhance production uptime, reduce costs, and enable sustainable manufacturing processes.

Sources:

- The Cost of Downtime 2024 | Siemens

- Value of Reliability: ABB Survey Report 2023 Industry’s perspective on maintenance and reliability | ABB

Key takeaways:

- IoT devices minimize downtime in a manufacturing plant by continuously monitoring equipment, processes, and material flow in real time.

- Predictive maintenance powered by IoT sensors helps detect early signs of equipment failure and prevents unplanned breakdowns.

- IoT-enabled automation triggers immediate corrective actions, such as adjusting machine settings or production speeds, to avoid disruptions.

- Edge computing, AI, and machine learning process IoT data faster, enabling instant responses and adaptive production lines.

- Operator-facing IoT tools, including wearables and AR interfaces, reduce response times by delivering real-time alerts and guidance.

- Historical IoT data supports long-term system redesigns that improve reliability and reduce recurring downtime.

FAQ

How does IoT technology reduce downtime in manufacturing plants?

IoT devices minimize downtime by enabling real-time monitoring of equipment and processes, facilitating immediate responses to potential issues. They integrate with edge computing and AI to create a more responsive manufacturing environment that addresses problems before they impact production.

What role do IoT wearables play in preventing manufacturing downtime?

IoT wearables provide operators with immediate, contextual alerts about equipment conditions and safety issues. This allows for faster response times to maintenance problems and helps prevent accidents, ultimately reducing both equipment-related and human-error downtime.

How does IoT improve process flow monitoring in manufacturing?

IoT sensors throughout production lines track material movement in real-time, identifying potential bottlenecks and inefficiencies before they escalate into costly stoppages. This continuous monitoring ensures smooth operations and prevents the "hurry up and wait" scenarios that often cause production halts.

Can IoT devices make automated adjustments to prevent downtime?

Yes, IoT sensors can trigger automated adjustments through Programmable Logic Controllers (PLCs) without human intervention. This self-correcting capability maintains continuous operations by addressing issues such as material-handling slowdowns or temperature variations that could affect product quality.

Is predictive maintenance the main way IoT reduces manufacturing downtime?

Predictive maintenance is a key use case, but it is not the only one. IoT also reduces downtime through process flow monitoring, real-time operator alerts, automated workflow corrections, and long-term system optimization based on historical data.

How does IoT contribute to long-term manufacturing improvements?

IoT devices collect valuable historical data that can be used to redesign and optimize systems. Machine learning algorithms coupled with IoT sensors create adaptive production environments that continuously evolve to maintain optimal operations. This fosters a culture of ongoing improvement, resulting in significant improvements in uptime over time.

Have a question?

Speak to an expert