As supply chains face growing pressure to operate with greater speed, precision, and adaptability, companies are reevaluating how they manage logistics and operations. According to KPMG, 57% of organizations consider AI essential to achieving their short-term supply chain goals [1].

One of the most promising ways to integrate AI in this context is through computer vision development. Such solutions help automate inspections, streamline workflows, and accelerate order fulfillment through faster item identification and handling.

However, implementing computer vision in supply chain environments requires reliable infrastructure, high-quality data, and seamless integration with existing systems. An end-to-end supply chain software development partner can help meet these conditions.

To understand CV's value in supply chain operations, it’s essential to start with its business benefits. From there, we’ll explore the most effective use cases, examine real-world case studies, and outline the key implementation practices that enable large-scale successful deployment.

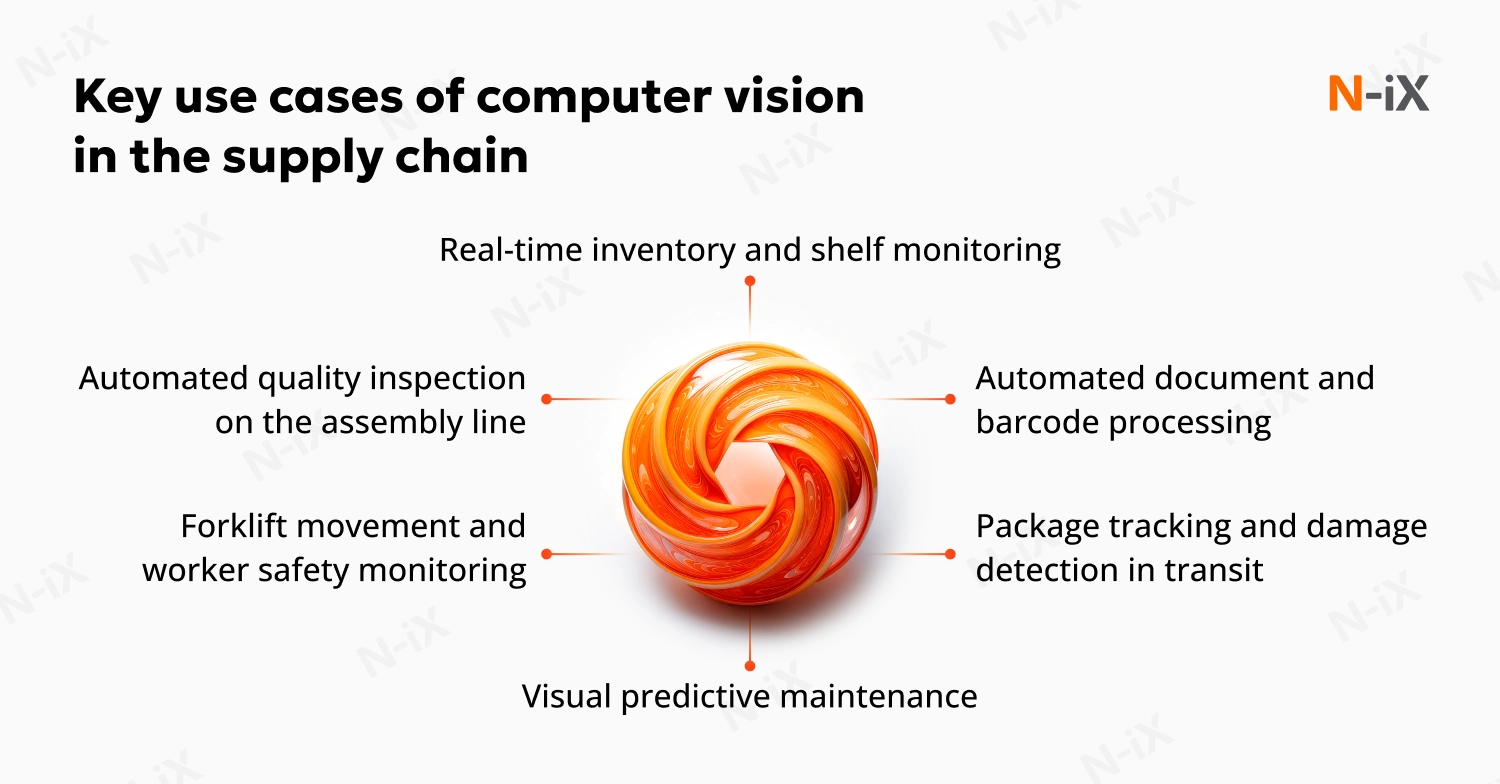

Key use cases of computer vision in the supply chain

Computer vision is increasingly used across supply chains to interpret visual data and support faster, more accurate decisions. According to IBM, organizations that invest more heavily in AI for supply chain operations report 61% higher revenue growth compared to peers [5]. The following six computer vision use cases show how to achieve better efficiency, safety, and visibility.

Automated quality inspection on the assembly line

Computer vision systems continuously monitor products on the assembly line, detecting defects such as misalignments, surface flaws, or incorrect assembly components. Deep learning models trained on historical defect data can spot anomalies with high precision in real time, far beyond human capabilities. These systems reduce scrap rates, minimize manual checks, and accelerate throughput without sacrificing quality. Manufacturers often deploy such solutions using widely adopted tools like TensorFlow and edge platforms such as NVIDIA Jetson for sub-second response times.

Real-time inventory and shelf monitoring

Visual AI eliminates the need for manual cycle counting by using fixed or mobile cameras to track inventory levels in warehouses or on retail shelves. CV models identify items, count units, and identify out-of-stock or misplaced products. These systems operate autonomously, often on edge devices, which means no dependency on cloud latency and better responsiveness on the ground. According to Gartner, by 2027, 50% of companies with warehouse operations will leverage AI-enabled vision systems to replace traditional scanning-based cycle-counting processes [4]. In such a way, CV improves inventory accuracy, reduces shrinkage, and supports real-time replenishment decisions.

Read more: Edge computer vision: Key industry use cases

Forklift movement and worker safety monitoring

Warehouses can significantly reduce accident risk by using computer vision in the supply chain to monitor vehicle traffic and detect unsafe behaviors in real time. Cameras track forklift routes, identify human presence in restricted zones, and trigger instant alerts if safety protocols are violated. These systems can be integrated with IoT infrastructure to enforce geofencing and hazard warnings automatically. Implementation typically involves lightweight edge computing setups and proven CV libraries such as OpenCV.

One example is a CV-powered traffic management solution by N-iX. The system was developed for a global provider of intelligent transport systems and focused on detecting seat belt violations and distracted driving behaviors in real time. It addressed challenges such as glare, variable lighting, and shifting camera angles and achieved 88% accuracy in identifying seat belt violations and 91% for detecting distracted behavior, all running at 30 FPS (frames per second). Its successful validation paved the way for regulatory approval and expansion into new markets.

Package tracking and damage detection in transit

CV models deployed in logistics hubs or inside delivery vehicles help detect damage such as dents, cracks, or packaging deformations as they happen. These systems visually track each item’s condition throughout the delivery cycle, enabling faster response when issues arise. Combined with embedded analytics and real-time logging, this approach enhances traceability and supports root-cause analysis in case of claims or complaints.

Get the guide to computer vision—learn how to implement it effectively!

Success!

Automated document and barcode processing

Computer vision powered by OCR (optical character recognition) and object detection models can rapidly process labels, barcodes, and shipping documents at scale. Unlike manual scanning, these systems operate continuously and handle diverse formats, fonts, and lighting conditions with high accuracy. Paired with natural language processing models, they can also extract and structure information from invoices, packing slips, and customs forms, dramatically improving processing speed at inbound, outbound, and customs control points.

Visual predictive maintenance

High-resolution cameras equipped with image recognition models can identify early indicators of equipment failure, such as oil leaks, cracks, or overheating, before breakdowns occur. These visual signals, analyzed in combination with data from IoT sensors, support more precise and cost-effective maintenance scheduling. CV-based condition monitoring helps extend equipment lifespan, reduce unplanned downtime, and shift maintenance from reactive to predictive mode.

Discover more: Supply chain analytics: Making data work for you

Benefits of computer vision in supply chain and logistics

According to KPMG, 67% of executives are expected to deliver more with smaller budgets [1]. Computer vision is one of the ways to achieve this productivity in supply chain operations since it strengthens execution across logistics, warehousing, and production. Let’s review the five impact areas where computer vision delivers practical value, supported by data from leading industry sources.

Accuracy and consistency

Computer vision models perform visual tasks with high precision, such as identifying defects, scanning barcodes, and verifying inventory. In fulfillment environments, the consistent performance of computer vision-guided systems improves quality inspection and reduces error-related costs, while manual processes often fall short under high load or variable lighting.

Speed and automation

AI-powered visual systems accelerate tasks that typically rely on human input. Label recognition, package classification, and document parsing are executed in real time with CV models trained on large annotated datasets. According to Accenture, supply chain leaders using AI, including computer vision, are eight times more likely to cut product launch cycles by 30% [2]. Faster cycle times support shorter lead times and better response to demand shifts.

Operational cost reduction

Computer vision reduces reliance on manual labor for routine tasks such as inspection, counting, and tracking. It minimizes rework, improves throughput, and enables leaner operations. Accenture found that companies applying AI at scale are 23% more profitable than competitors [2]. These gains result from fewer errors, higher equipment utilization, and more efficient workflows.

Learn more: Generative AI in supply chain: use cases and applications

Improved compliance and safety

Vision-based systems support workplace safety and regulatory compliance by identifying risky behaviors, unsafe conditions, and protocol non-compliance. Deloitte reports that one industrial firm reduced safety incidents to zero after deploying a computer vision-based monitoring system with predictive capabilities [3]. These outcomes were made possible through real-time video analysis and integration with IoT-based alert systems.

Read more about prominent use cases of computer vision in security

Competitive and sustainability advantages

While only 9% of organizations use AI and generative AI widely across their supply chains, that number rises to 37% among industry leaders. These leaders are seeing a measurable impact. According to Accenture, they are 8.5 times more likely to develop eco-friendly products and six times more likely to improve engineering efficiency by 30% [2].

Computer vision plays a key role in enabling these gains in the supply chain. It supports automation, improves resource allocation, and enhances end-to-end visibility across logistics, production, and fulfillment. Let’s review how computer vision can be applied across supply chain operations in real-world scenarios.

Implementing computer vision in supply chain: Success story by N-iX

Our client, a global Fortune 100 industrial engineering and technology firm, aimed to enhance efficiency and scalability across its logistics platform, which spanned over 400 warehouses in 60 countries. To achieve this goal, the company prioritized modernizing internal logistics processes, including package tracking, barcode scanning, and damage detection, that were previously constrained by a monolithic system.

N-iX delivered a modern, cloud-native, microservices-based architecture on Azure Kubernetes, enabling modular expansion to include services like anomaly detection, delivery prediction, and multiple computer vision capabilities. Our solution included an automated ML lifecycle (training, testing, deployment, monitoring) and the development of a multiplatform mobile CV app supporting object detection, package damage detection, OCR, and NLP for real-time warehouse operations.

The solution helped our client to gain significant business and technical benefits:

- Automated manual workflows and reduced paperwork;

- Real-time package tracking and delivery status updates;

- Automated barcode scanning and damage detection under varied conditions;

- Scalable deployment across more than 400 warehouses in 60 countries;

- Enhanced infrastructure flexibility through cloud-agnostic microservices.

Read more: Driving logistics efficiency with industrial Machine Learning

How to implement computer vision in supply chain

Computer vision implementation for the supply chain sector requires more than building a model. It involves aligning business goals, engineering scalable infrastructure, and ensuring long-term performance in live environments. At N-iX, we support enterprises at every stage of this process, combining CV expertise with deep supply chain knowledge. Below is a step-by-step approach based on implementation best practices we follow with global clients.

1. Define the business objective and key metrics

The first step is to define a concrete operational objective. Focus on a specific area with measurable inefficiencies, such as mislabeling, safety violations, or damage during transit. Without clearly defined metrics, it becomes difficult to evaluate impact or justify investment. We recommend identifying 1-2 high-priority workflows and establishing relevant KPIs, such as false-positive rates, inspection cycle time, or unit throughput.

2. Collect and annotate relevant data

Data quality directly impacts model performance. Successful CV initiatives require domain-specific datasets representative of real-world conditions, including variations in lighting, camera angles, and object types. We advise capturing video or image data from live operations and using structured annotation practices. At N-iX, we often establish dedicated annotation pipelines with quality assurance loops to accelerate training cycles while maintaining high labeling accuracy. When edge conditions are complex, we supplement datasets with synthetic or augmented data to improve generalization.

3. Choose the right CV model

Model selection depends on latency requirements, hardware constraints, and the complexity of the detection task. For fast-moving environments like warehouse inspection or vehicle tracking, we often recommend YOLO or SSD architectures optimized for real-time inference. For tasks involving finer visual differentiation, we may use ResNet-based classifiers or image segmentation models. N-iX provides both cloud-based and on-device training options, using platforms like TensorFlow, PyTorch, and NVIDIA’s Transfer Learning Toolkit.

4. Build a scalable inference pipeline

Inference pipelines must be robust, fast, and integrated with operational systems. We build pipelines capable of processing high-resolution video feeds in real time, either on edge devices like NVIDIA Jetson or through scalable cloud services on AWS or Azure. Our engineers use containerized microservices and message queues to orchestrate model inference, data capture, and event-driven notifications. This architecture ensures consistent performance across facilities and allows for rapid deployment of updated models without service interruption.

5. Integrate with supply chain systems

To generate value, CV outputs must feed into the systems that drive decisions, such as warehouse management systems (WMS), enterprise resource planning (ERP), or transportation platforms. At N-iX, we prioritize integration planning early and provide connectors or APIs that enable seamless communication between visual pipelines and supply chain software. Such an approach ensures that computer vision insights translate into immediate, actionable outcomes within existing supply chain systems.

6. Monitor, retrain, and optimize

Model performance will degrade over time due to environmental changes, equipment wear, or shifting product lines. To sustain its accuracy in production, we implement model versioning, A/B testing, and automated retraining pipelines. Our MLOps teams monitor both technical metrics (latency, confidence scores) and business KPIs (error reduction, compliance rates). Feedback loops ensure that new data continuously improves future iterations. This lifecycle management is essential to avoid performance drift and preserve ROI over the long term.

Conclusion

Computer vision in supply chain environments improves operational speed, precision, and traceability. It improves defect detection, reduces downtime, enhances workplace safety, and accelerates key workflows such as inventory audits and shipment validation. As its adoption expands, the focus is shifting from isolated use cases to scalable, integrated systems that deliver measurable ROI across warehouses, transport networks, and production sites.

N‑iX is a proven software development partner with a strong record of delivering enterprise-grade CV solutions. With 2,400 professionals on board, including 200 data and AI experts as well as 70 DevOps engineers, we support clients at every stage of the computer vision lifecycle. From data strategy and model development to edge deployment and integration with WMS or ERP platforms, we build reliable systems that deliver lasting operational value.

References

- KPMG. Accelerate supply chain value with a targeted strategy for AI.

- Accenture. Companies with Next-Generation Supply Chain Capabilities Achieve 23% Greater Profitability, Shows New Research from Accenture.

- Deloitte. Managing a modern supply chain: Utilizing AI to combat complexity.

- Gartner. Gartner Predicts Half of Companies With Warehouse Operations Will Leverage AI-Enabled Vision Systems by 2027.

- IBM. Scaling supply chain resilience: Agentic AI for autonomous operations.

Have a question?

Speak to an expert