With the help of industrial Internet of Things (IIoT) development, the machines can sense and report everything, from vibration to voltage. However, they rarely decide what to do next. This is changing with the development of AI agents in industrial IoT.

This article covers what industrial AI agents in IoT are, why they matter in manufacturing, and how they can be used in industrial operations.

What are AI agents in industrial IoT, and how do they work?

An AI agent is a goal-oriented software system that observes its environment, analyzes the information it receives, and acts to achieve specific objectives. In an industrial context, these agents monitor equipment data, detect anomalies, predict failures, or optimize production schedules in real time.

They also bridge the gap between connected assets and intelligent action, helping manufacturers make their operations more adaptive, predictive, and efficient. Think of them as "digital co-workers" embedded into your IoT ecosystem that watch sensors, make micro-decisions, and learn from every outcome.

Approach your IoT project avoiding major risks—get the guide!

Success!

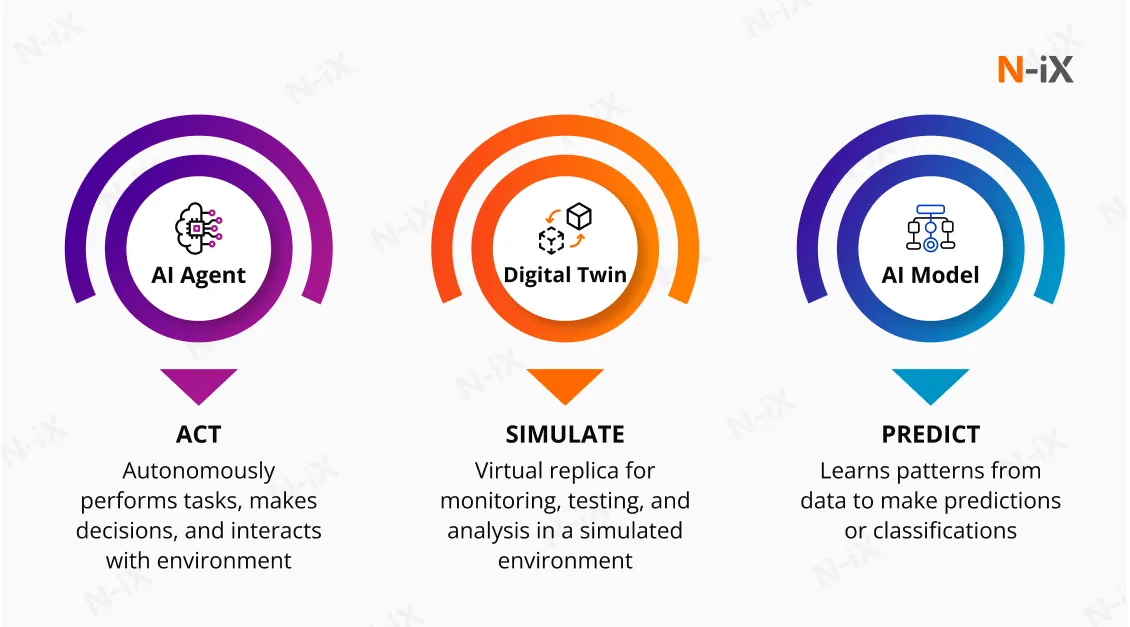

Sometimes, the term "AI agents" is used interchangeably with AI models, and can be mistaken for "digital twin". While related, they represent different things.

How AI agents in IIoT differ from digital twins and standard AI models

While all three technologies use data and intelligence, they serve different purposes in the industrial ecosystem.

- IIoT AI agents are autonomous systems that observe, decide, and act in real time.

- Digital twins are virtual replicas of physical assets or processes used for simulation and predictive analysis.

- Standard AI models are algorithms trained for specific tasks, like classification or prediction, but they don't act autonomously.

Unlike traditional automation or static rule-based AI systems, AI agents in IIoT systems can adapt to changing conditions. They don't just execute commands; they decide when and how to act. For instance, an agent can analyze temperature and vibration data, forecast a bearing failure, and automatically schedule maintenance before a costly breakdown occurs.

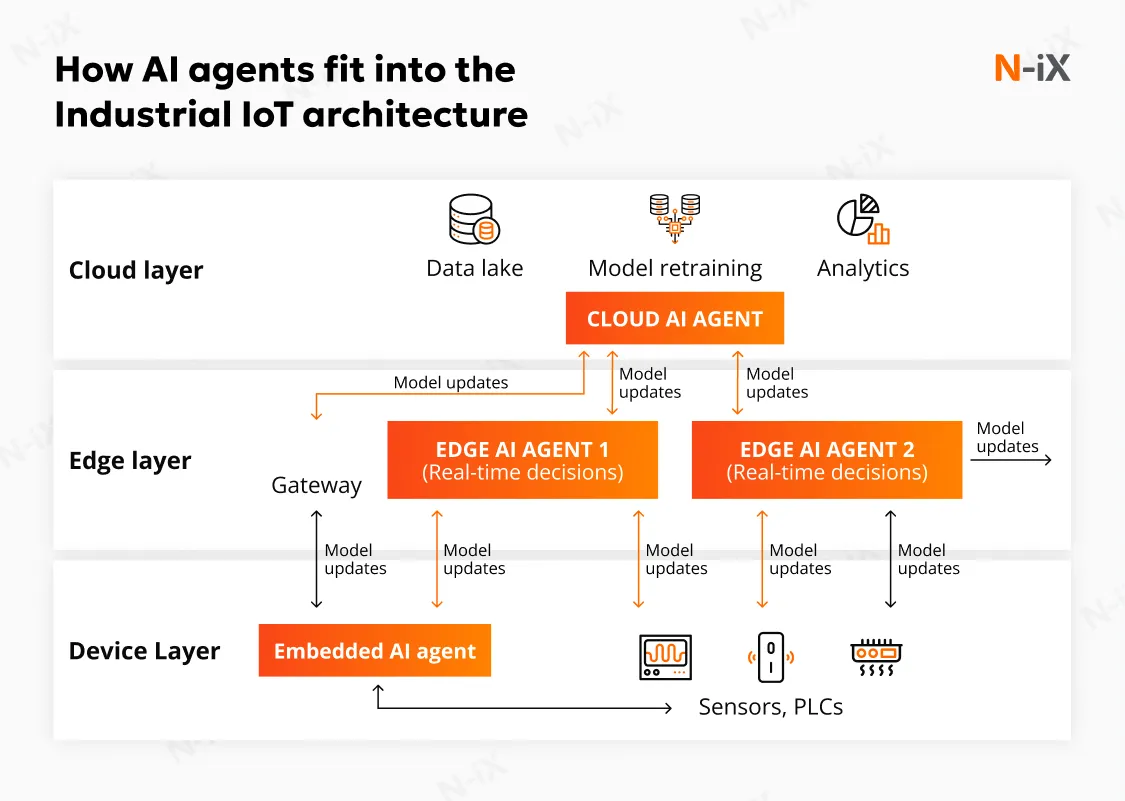

How AI agents fit into the Industrial IoT architecture

In an industrial setup, AI agents operate across several layers of the IIoT stack. At the device layer, sensors and controllers collect operational data from machines. The edge layer hosts on-device AI models that process this data locally, enabling instant responses and minimal latency. In the cloud, aggregated data is analyzed, models are retrained, and insights are shared back to edge agents for continuous improvement.

This distributed architecture, device, edge, and cloud, ensures both real-time responsiveness and long-term optimization. It forms the backbone of modern, AI-driven industrial ecosystems. But that's not the only reason industrial AI agents in IoT matter.

More domain insights: Industrial IoT use cases: 15 examples that change business

Why AI agents in Industrial Internet of Things matter

Sensors, edge devices, and cloud infrastructure now generate immense volumes of machine data. The challenge is how to make sense of that data fast enough, act on it, and do so with the minimum human intervention while ensuring reliability and performance. Artificial Intelligence agents in IIoT help deal with this. They interpret signals at the edge, trigger timely responses, and improve accuracy through feedback loops.

Beyond efficiency, there's strategic value too. The ability to respond instantly to real-world changes gives industrial companies a competitive advantage. Usually, it means more resilient supply chains, faster production recovery, and reduced waste.

However, adopting AI agents in IIoT requires already existing practices regarding AI, connectivity, and data. Here's what makes the proper functioning of AI agents in an industrial IoT environment possible.

What enables AI agents in industrial IoT

As AI capabilities move closer to the data source, the Industrial Internet of Things is evolving into AIoT, the mix of AI and IoT. AI and Machine Learning make IoT devices smarter by allowing them to analyze data and make decisions on their own. In turn, IoT connects these devices and provides the data they need. Together, they are used in AIoT applications that act and learn in real time.

Another factor enabling AI agents' adoption in IIoT is how sensor data is distributed. Instead of sending all sensor data to the cloud for processing, on-device AI allows machines and edge devices to analyze data locally, respond instantly, and keep operating even with limited connectivity.

In manufacturing and energy environments, this shift reduces latency, improves reliability, and lowers bandwidth costs. It also allows AI agents to run directly on gateways, PLCs, and embedded devices, making decisions at the source in real time.

By adopting AIoT and on-device AI, businesses gain faster insights, safer operations, and more resilient production ecosystems. This is the foundation on which industrial AI agents in IoT can function. Let's explore how industrial businesses can leverage the power of IoT AI agents.

How businesses can use AI agents in industrial IoT

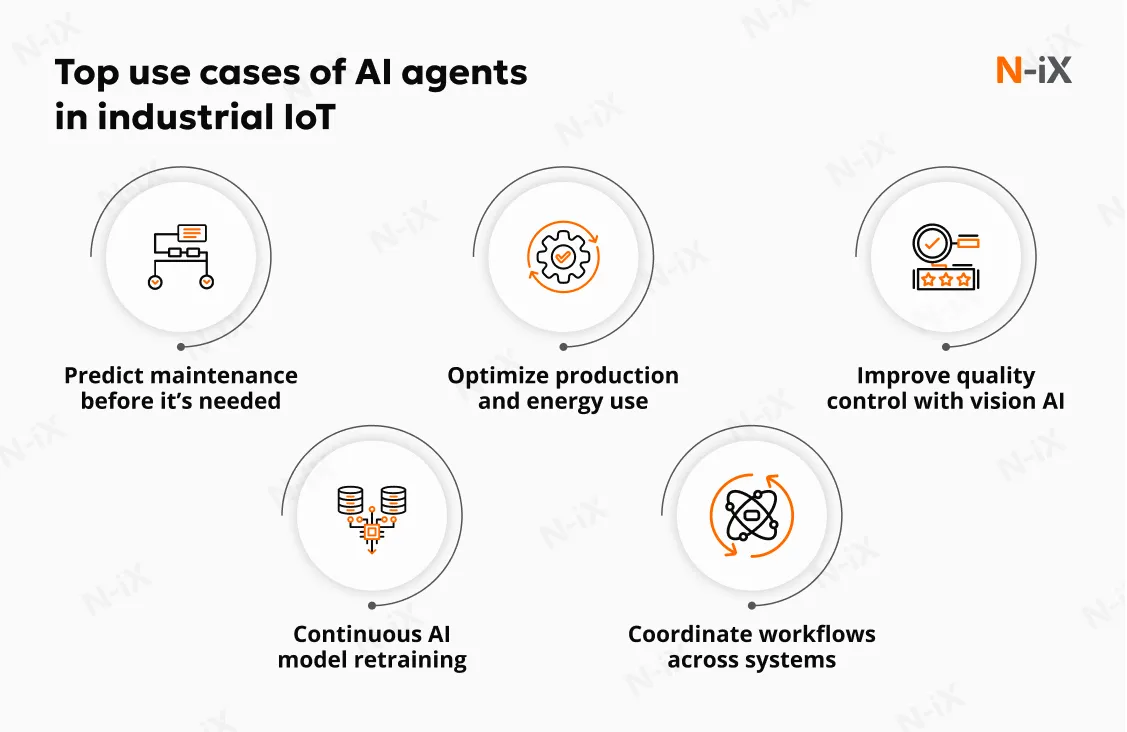

Predict maintenance before it's needed

Sensors stream vibration, temperature, and pressure data from critical assets. Industrial AI agents in IoT analyze these patterns and predict component wear or imminent failures. When risk thresholds are met, they can automatically trigger maintenance work orders in computerized maintenance management systems (CMMSs) or alert technicians. It helps the manufacturing business avoid costly unplanned downtime.

Learn more about the top use cases and examples of IoT predictive maintenance

Optimize production and energy use

AI agents in industrial IoT systems can monitor process parameters and energy consumption in real time. AI agents can dynamically adjust workloads, recommend optimal machine settings, and identify inefficiencies by continuously monitoring process parameters, energy consumption, and machine performance in real time. This proactive approach helps minimize energy waste, balance production output with demand, and maintain consistent product quality.

Moreover, IoT AI agents in industrial environments can integrate with predictive maintenance systems, ensuring that equipment operates at peak efficiency. This reduces downtime and extends the lifespan of machines, resulting in significant cost savings and a more sustainable production process.

Improve quality control with vision AI

AI agents in IIoT can automatically detect visual defects in products during manufacturing when integrated with Computer Vision (CV). This is widely implemented in automotive, electronics, and packaging industries, where visual inspection is key.

CV algorithms can recognize patterns or anomalies, such as scratches, dents, or color inconsistencies. Industrial AI agents in IoT can also flag anomalies during production, allowing for immediate corrections or interventions. This reduces human error and accelerates decision-making in real time. The agents help catch the issues earlier in the production line, improving overall efficiency. As a result, AI agents in industrial IoT powered by CV contribute to higher throughput and lower scrap rates, directly impacting cost savings.

Explore the topic: Agentic AI in manufacturing: The executive's guide

Continuous AI model retraining

The business can use Machine Learning to retrain AI models to adapt to new dynamics and patterns. Retraining is typically done using historical defect data, which enables the system to adjust to evolving production processes. Over time, the system can adapt to detect even subtle new defects, improving accuracy and robustness. As a result, continuous retraining keeps AI agents aligned with real-world production dynamics and ensures sustained reliability and performance.

Coordinate workflows across systems

In complex smart manufacturing environments, IoT AI agents collaborate to synchronize operations across machines, lines, and facilities. They can balance workloads, reroute tasks, and allocate resources to maintain throughput even during disruptions. And they do so by sharing data with different systems in real time.

This coordination minimizes idle time and bottlenecks and improves line utilization and overall equipment effectiveness. Integrated through cloud-edge orchestration or digital twins, connected agents continuously refine collaboration patterns. As a result, the large-scale production becomes more agile and self-optimizing.

Explore the topic: IoT in smart manufacturing: Insights for enterprises

Adoption maturity stages of AI agent in the Industrial Internet of Things

Most organizations start small, with a single predictive-maintenance use case or one production line. And it makes sense. It helps build trust in the data and the models before scaling, face the potential constraints of the selected area, and develop a working case study specific to your production environment.

Companies usually progress through four stages when implementing AI agents in Industrial IoT.

- Level 1: Proof of concept (PoC). A single use case, such as predictive maintenance for one machine or line.

- Level 2: Pilot deployment. Multiple connected assets with partial automation and human validation of agent decisions.

- Level 3: Scaled operations. Standardized AI agent templates deployed across lines or plants, with integrated monitoring and governance.

- Level 4: Autonomous ecosystem. Fully orchestrated multi-agent system spanning facilities, using real-time data and self-learning to optimize end-to-end performance.

Understanding your current maturity level helps define the right roadmap, investment scope, and technology stack for sustainable adoption. Here are a few tips to make this process smoother and more structured.

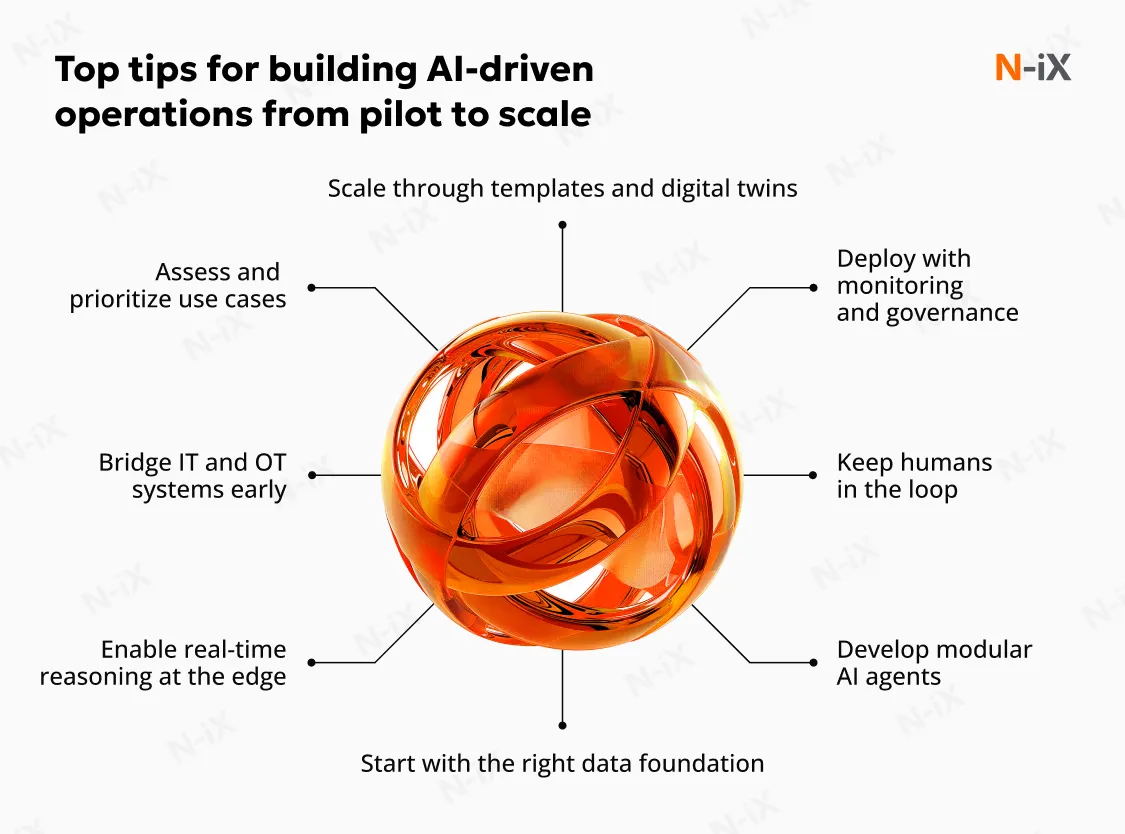

Top tips for adopting AI agents for IIoT from pilot to scale

Adopting AI agents in Industrial IoT is not a single leap-it's an unfolding project. Starting small helps validate both technology and culture before scaling across the enterprise. Done right, this helps manufacturers prevent data chaos and fragmented integrations. Here are a few practical steps to guide you through your AI agent adoption journey.

Assess and prioritize use cases

Begin with the highest-impact areas such as assets with frequent downtime, energy inefficiencies, or costly quality deviations. Evaluate data availability and define measurable success criteria early.

Bridge IT and OT systems early

Reliable agents depend on the integration of IT (information technology) and OT (operational technology), called IT/OT convergence. The bridge between them enables secure, low-latency data exchange between production equipment and enterprise systems. Standards like OPC UA, MQTT, and Edge-to-Cloud connectors make this possible while maintaining control and safety boundaries. Without this bridge, AI agents can't operate with full visibility of production processes.

Enable real-time reasoning at the edge

AI agents in IIoT must often make decisions locally, close to where data is generated. Deploying AI on edge devices or industrial gateways reduces latency and improves reliability, even when connectivity to the cloud is limited.

Start with the right data foundation

AI agents learn from operational data-sensor readings, machine logs, PLC outputs, MES reports, and maintenance records. This data must be high-quality, time-synchronized, and contextualized. Creating a centralized industrial data lake or historian helps organize and clean this data before it's fed into training pipelines.

Develop modular IoT AI agents

Design agents as modular, reusable components that combine AI models, domain logic, and edge computing. Use containerization to streamline deployment and updates. This approach reduces development time and simplifies scaling across different assets and sites.

Keep humans in the loop

Before full automation, let human operators validate agent decisions. This ensures safety, builds operator trust, and creates valuable labeled data for retraining. Over time, gradually transition from human oversight to supervised autonomy.

Deploy with monitoring and governance

Once industrial AI agents in IoT systems prove reliable, roll them out systematically across similar assets or plants. Embed monitoring dashboards to track model performance, detect drift, and ensure compliance with industrial and safety standards. Governance at this stage prevents bias and ensures auditability, maintaining consistent behavior at scale.

Scale through templates and digital twins

Use proven agent configurations as templates for new environments. Integrating them with digital twins helps simulate outcomes before deployment and accelerate safe and cost-effective scaling.

As your business matures, the challenge shifts from experimentation with AI agents to orchestration. It means you'll need to connect dozens of agents into one intelligent, adaptive network. Having a reliable tech partner by your side will help you deal with the challenges at any stage of this process. Here's how partnering with N-iX can make a difference.

Discover more insights: Why Generative AI at the edge is the next big tech move

Where N-iX can help

At N-iX, we work with global manufacturing, logistics and supply chain, telecom, automotive, healthcare, energy, and other businesses to help them use connected data to improve and automate their operations. By combining domain expertise, advanced data engineering, and proven experience with AI agent development for industrial environments, we help you move from pilots to production-ready, scalable AI-driven operations.

Our expertise spans:

- IoT development services. N-iX offers end-to-end IoT solution development from IoT consulting, device IoT connectivity, and data ingestion to edge-to-cloud architectures.

- AI consulting and implementation. We help you turn business goals into practical AI agent use cases and safe, governed deployments.

- Edge computing AI and analytics. Our engineers help deploy AI and ML models directly on gateways or embedded systems for low-latency decision-making.

- Data engineering and integration. We build scalable, interoperable data pipelines, data warehouses, and data lakes and integrate them with enterprise systems.

- Cloud development and engineering. We have over 400 cloud experts to build secure, scalable cloud infrastructures on AWS, Azure, or GCP to support AI model training, deployment, and cross-factory data orchestration.

- Computer Vision development services. N-iX's CV engineers design and implement visual AI systems for defect detection, object tracking, and process monitoring to enhance quality control and operational safety.

- Big Data. Our capabilities help clients build solutions that collect, store, and analyze massive volumes of industrial data to uncover patterns, optimize workflows, and power AI agent learning.

Whether you're modernizing legacy automation, scaling predictive maintenance, or building a digital twin of your production ecosystem, N-iX helps design, implement, and operationalize AI agents that align with your business goals.

Final thoughts

AI agents in industrial IoT aren't just a glimpse of the future-they're an attainable advantage today. The technology, infrastructure, and expertise are already here, allowing adopters to predict and plan maintenance more accurately, optimize production and energy use, improve quality control, and more. If you're ready to explore where autonomous intelligence can add the most value to your operations, N-iX can guide you from assessment to pilot and adoption at scale.

Have a question?

Speak to an expert