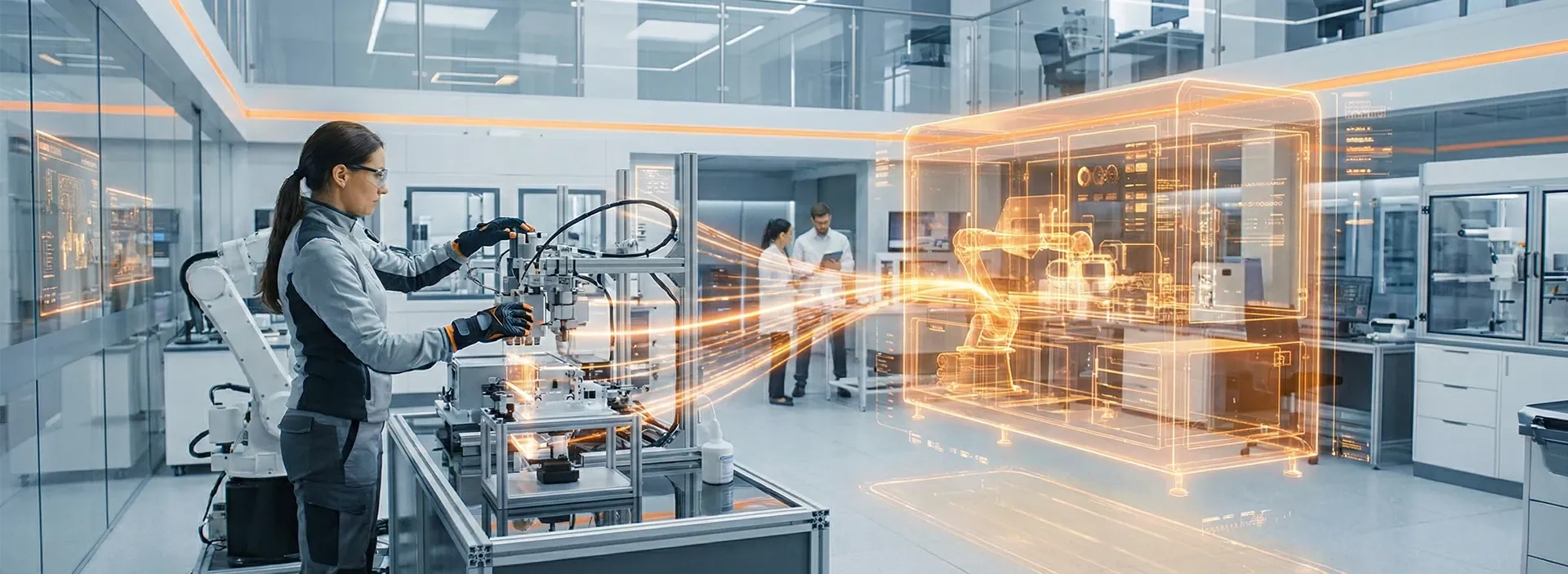

For CTOs and business leaders, understanding how IoT and digital twins complement each other is essential to creating their own adoption strategy. From reducing downtime to improving operational efficiency and driving innovation, the merging of these technologies is already reshaping industries worldwide. But how are companies embracing the convergence of physical and digital operations, and what lessons can be learned from their journeys?

In this article, we'll dive into how organizations are adopting IoT and digital twins, why they're crucial for the future, and how your company can leverage these technologies to lead in the cyber-physical era. We'll also share how N-iX, as a custom software development company with expertise in IoT development and digital twin consulting, can help you seamlessly integrate IoT and digital twin solutions tailored to your business.

What is a digital twin in IoT?

A digital twin is a virtual replica of a physical asset or system that is continuously updated with real-time data from simulation or other data sources. If the data is streamed from IoT sensors, the system may be called an IoT digital twin. The IoT devices collect and transmit data that feed directly into the digital twin, enabling accurate simulations, monitoring, and predictive insights based on the physical asset's actual conditions and performance. These data streams are called digital threads.

For companies aiming to thrive in the cyber-physical era, understanding the synergy between IoT and digital twins is paramount. These technologies are not just tools, but the foundation of a smarter, more agile operations.

What's driving the need for IoT and digital twin technologies?

The rise of IoT and digital twins is transforming how companies operate and make decisions. IoT enables the real-time collection and transmission of data from physical assets. At the same time, digital twins bring this data to life as virtual models that simulate and predict asset behavior. Together, they create a digital ecosystem where physical and digital worlds converge, giving companies more visibility into their operations.

Approach your IoT project avoiding major risks—get the guide!

Success!

As these technologies mature, they are being adopted across industries that thrive on innovation and efficiency, such as manufacturing, energy, transportation, and healthcare. But it's not just about adopting new tech. For companies to truly thrive in this cyber-physical era, they must build a solid strategy that integrates both IoT and digital twins to align with their broader business objectives. And to do so, the companies need to take a close look at a few key things:

- IoT and digital twin architecture;

- Types of digital twins;

- Market context.

Let's review them.

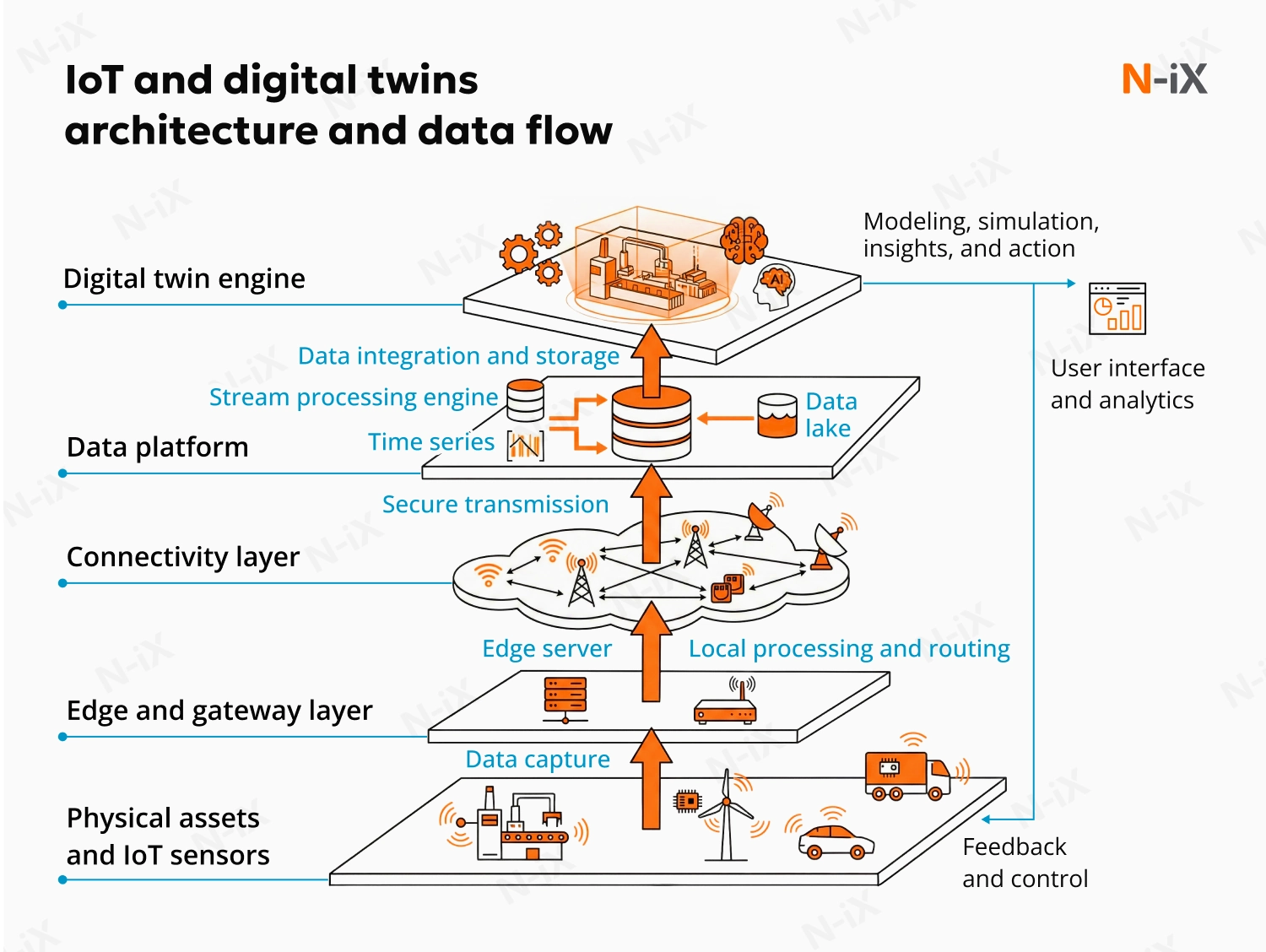

IoT and digital twin technology architecture

The architecture of IoT and digital twin systems is typically structured across multiple layers that ensure seamless data flow from physical assets to actionable insights.

- Physical assets and IoT sensors. Sensors capture real-time data from physical assets, such as temperature, vibration, or pressure, ensuring the right data is collected at the appropriate frequency for accurate monitoring and decision-making.

- Edge and gateway layer. This layer processes data locally, allowing for low-latency processing and resilience, especially when operating in remote or distributed environments.

- IoT connectivity layer. It ensures reliable data transmission across networks, handling legacy systems, proprietary protocols, and network segmentation to facilitate communication between IoT devices and platforms.

- IoT data platform. The platform receives, stores, and processes time series, event, and status data at scale, making it ready for further analysis and integration with other systems.

- Digital twin engine. The digital twin engine creates virtual models using IoT data, which can be either physics-based or powered by Machine Learning (ML) models, depending on the complexity of the system and its integration with the IoT platform.

For visualization and integration, digital twins must connect to enterprise systems like ERP, MES, PLM, and CMMS. This ensures that insights from the twin are actionable in real-time, allowing operators to adjust processes or trigger maintenance directly from the system.

When it comes to governance and scalability, managing data consistency and versioning is key. As your IoT and digital twin network grows, having standardized data models and strong governance practices ensures the system remains accurate and secure as it scales across operations.

More on topic: Digital twins in manufacturing: Benefits, technologies and use cases

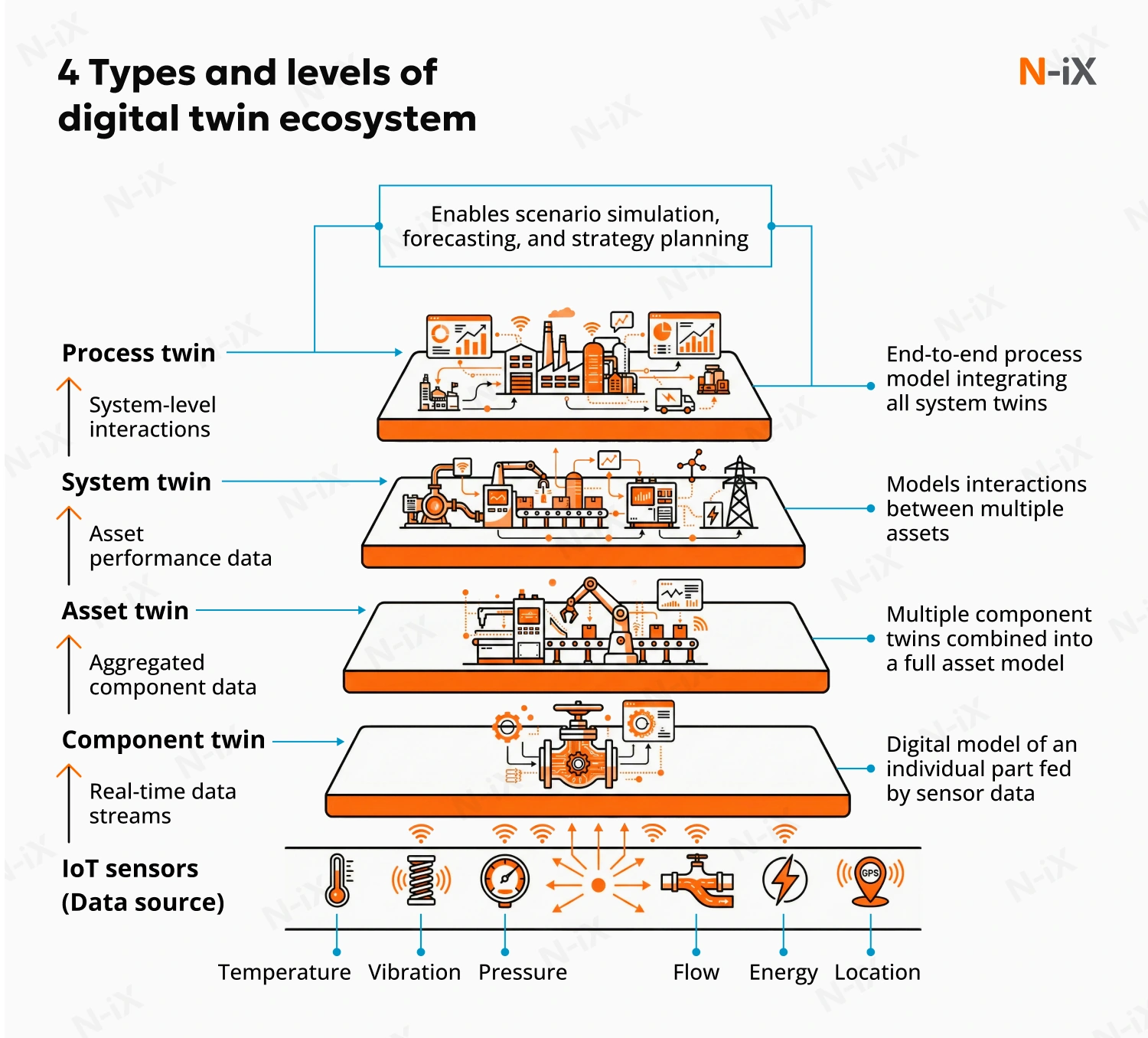

Types of digital twins

Understanding the different types of digital twins helps companies see how their data and operational needs evolve as they scale from monitoring single components to optimizing entire processes. As businesses progress from component to asset, system, and process twins, the amount of real-time data required grows exponentially. IoT can provide the continuous, high-quality data streams needed to power these increasingly complex models. Here's an overview of the main types of digital twins and how IoT is connected with each.

Component twin

A component twin represents a specific part or component of an asset, capturing real-time performance and operational data to help predict maintenance needs. IoT sensors embedded in individual parts (e.g., valves, switches, bearings, circuit boards) collect real-time data such as temperature, vibration, pressure, or electrical load. This data feeds directly into the component twin, ensuring the digital model reflects the exact condition and performance of that specific element.

Example: A component twin of a car engine tracks temperature, pressure, and wear data to predict maintenance needs.

Asset twin

An asset twin represents an entire asset, such as a machine, vehicle, or piece of equipment. IoT data from multiple component twins is aggregated to build a real-time view of how the entire asset behaves. Sensors across an engine, pump, HVAC unit, or robot arm capture performance metrics that the asset twin uses to model efficiency, reliability, mean time to repair (MTTR), and mean time before failure (MTBF).

Example: A digital twin of a wind turbine monitors operational data from the blades, motor, and gearbox to optimize energy production and schedule maintenance.

System twin

A system twin models multiple assets or components that work together within a system. IoT devices across several assets stream synchronized data into a system-level digital twin, which models how assets interact as a functional unit (a production line, energy distribution system, packaging station, etc.). Without IoT data, the system twin cannot accurately simulate interdependencies or real-time system behavior.

Example: A system twin of a production line in a factory models how machinery, workers, and materials interact to improve throughput and reduce bottlenecks.

More insights for enterprises on IoT in smart manufacturing

Process twin

A process twin models entire workflows, such as production, logistics, or supply chain operations. At this highest level, IoT provides continuous data streams from entire workflows, connecting multiple system twins into an end-to-end view of the organization's processes. Data from sensors, equipment, environmental monitors, and even ERP/MES/PLM systems feed the process twin.

Example: A process twin of a manufacturing process simulates the entire production sequence, enabling real-time monitoring of quality, cycle times, and resource allocation.

Each higher-level twin often requires more complex data inputs, making IoT an essential component for feeding accurate, detailed information into the models, particularly for dynamic, real-time decision-making. This connection drives organizations to adopt both IoT and digital twin technologies together to achieve reliable insights and scalable cyber-physical systems.

Market context of IoT and digital twins

Digital twins began as virtual replicas of components, assets, or processes. However, when paired with other technologies such as AI, IoT, and AR/VR, they exited the static, pre-programmed realm. As the IoT Analytics article mentions, digital twins are now becoming AI-driven optimization tools [1]. The demos from EDAG Engineering and Siemens at Hannover Messe 2025 have shown how they work in real-life scenarios at the smart factory and robotic training, respectively.

With simulation being among the major use cases of digital twins, this market segment is expanding. As Gartner predicts, the share of simulation digital twin (SDT)-enabling software and services will grow from $35B in 2024 to $379B by 2034 [2]. Within this area, the researcher expects the emergence of different types of SDTs:

- Simulation digital twin of a thing (SDToT) to mirror the performance of assets. This type relies heavily on IoT technology and is the most mature to date.

- Simulation digital twin of a person (SDToP) to mirror individual and group multipresence in cyber and physical spaces. Its major markets are security, travel, and smart factories, among others.

- Simulation digital twin of composite processes (SDToCP) to monitor and improve business-level outcomes. This type is the least mature and most complex, as it requires integrating different digital twins to simulate high-level outcomes.

The use of IoT and digital twins has become increasingly popular in supply chain domains, with their own solutions typically called digital supply chain twins (DSCTs). According to the 2024 Gartner Future of Supply Chain Survey, about 76% of respondents plan or are implementing DSCT in their operations to increase visibility and agility across their supply chain.

While the market figures point to the development of IoT and digital twins, some companies have already combined these technologies to improve their cyber-physical operations. Here are a few cases where the convergence of digital twins and IoT made an impact.

In a world where data is king, IoT and digital twins provide the critical infrastructure for turning raw information into actionable insights. By adopting these technologies, businesses don't just keep pace with innovation—they move it. However, a successful implementation requires careful planning, robust data governance, and a clear strategy to ensure that these technologies align with broader business goals. And that's where N-iX can help.

Convergence of IoT and digital twins: Examples of adoption across industries

The use of IoT digital twins across industries adds tremendous value to optimization and management. For example, a McKinsey article describes how the development and deployment of IoT-connected digital twins at an industrial site has helped the business redesign the production schedule, reducing overtime requirements [3]. As a result, the assembly plant achieved up to 7% monthly cost savings. And that's not the only case worth taking notes on.

Logistics and supply chain: DHL

DHL Supply Chain partnered with Tetra Pak to implement a digital twin solution for Tetra Pak's warehouse operations in Singapore, combining IoT technology with data analytics [4]. This integration bridged the physical warehouse with virtual copies of assets, enabling real-time monitoring and operational simulations. The adoption of this technology improved safety, productivity, and operational efficiency by enhancing spatial awareness and reducing risks, such as collisions. The IoT sensors on materials handling equipment (MHE) and digital twin enabled 24/7 coordination of operations, real-time decision-making, and efficient flow of goods. The facility in Singapore operates round the clock, coordinated by DHL Control Tower.

Lessons for businesses: Combining IoT with digital twins in operations enhances real-time decision-making, optimizes resource planning, and significantly improves safety and efficiency across complex systems.

Explore further: Digital twins in healthcare: Transforming patient care and operations

Oil and gas: Shell

Norske Shell, in collaboration with Gassco and Kongsberg Digital, implemented the Nyhamna Dynamic Digital Twin [5]. The virtual model integrates real-time data from IoT-connected sensors, visualizations, and modeling at the asset, equipment, and component levels to optimize operations at the Nyhamna facility. This digital twin enabled better decision-making, improved efficiency, and reduced operating costs by $3M in its first year. By simulating real-world scenarios, the twin helps Nyhamna improve work processes, reduce energy consumption, and enhance resilience. The next phase is scaling the digital twin to the Ormen Lange field, creating a 'reservoir to market' model to optimize production and reduce environmental impact.

Lessons for businesses: IoT and digital twin integration drives significant cost savings, operational efficiency, and scalable transformation.

Transportation: Hymer

Hymer used a digital twin to streamline its recreational vehicle (RV) development process, leveraging Siemens' Solid Edge and NX CAD for 3D modeling and Teamcenter PLM for virtual prototyping [6]. By leveraging IoT data from sensors in the NX CAD solution, the team enabled real-time data flow to the digital twin, facilitating more accurate simulations and enabling more efficient production workflows. This integration allowed the company to improve design verification and reduce physical mockups by 80%. By enriching models with product and manufacturing information (PMI), the team accelerated the development of customized variants by 65%.

Lessons for businesses: Adopting digital twins and IoT can accelerate product development, enhance customization, and improve collaboration across teams.

Read more: Guide to digital twins technology in retail

Automotive manufacturing: BMW

The BMW Group is one of the major adopters of advanced digital twin solutions and industrial IoT in automotive manufacturing. It has been using digital twins with IoT extensively since 2020, after working with NVIDIA's Omniverse to create its Virtual Factory. As of 2022, all of the BMW Group's production sites have been captured in a 3D scan, creating a network of digital twins [7].

Having 3D scans and IoT data, BMW's Virtual Factory simulated production lines in real time. It resulted in faster integration of then-new vehicle models, such as the BMW iX1, into existing production systems. This adoption is predicted to reduce production planning costs by 30% [8]. Moreover, digital twins now enable virtual collision checks, which take up to three days rather than the previous four weeks of real-world testing.

Lessons for businesses: IoT and digital twins can enable virtual simulations, accelerate product launches, reduce costs, and optimize production efficiency at a global scale.

Learn about the real-world impact of digital twins applications

Aerospace: Airbus

Airbus has adopted digital twins across its design, manufacturing, and operational processes, creating virtual representations of aircraft, production lines, and supply chains [9]. By integrating IoT sensors with real-time data, Airbus can simulate the behavior of aircraft such as the A320 and A350, significantly reducing the need for physical prototypes, thereby accelerating time-to-market and enhancing design accuracy.

The digital twin technology also plays a key role in predictive maintenance for over 12,000 aircraft connected to the Skywise platform, enabling real-time transmission of data from aircraft sensors to their respective digital replicas. It allows the crew to schedule proactive maintenance, reducing downtime and increasing fleet availability.

Lessons for businesses: Digital twins and IoT accelerate product development, reduce physical prototyping costs, and enable predictive maintenance, improving fleet efficiency and safety while minimizing downtime throughout the aircraft lifecycle.

These are just a few of the cases where IoT and digital twin technology have benefited enterprises across the business domains. The reason behind this success lies in the thought-out strategy, its correct execution, and considering challenges that may hinder the project. Here are a few things you need to consider and address for a smooth start.

Explore what every executive should know about IoT predictive maintenance

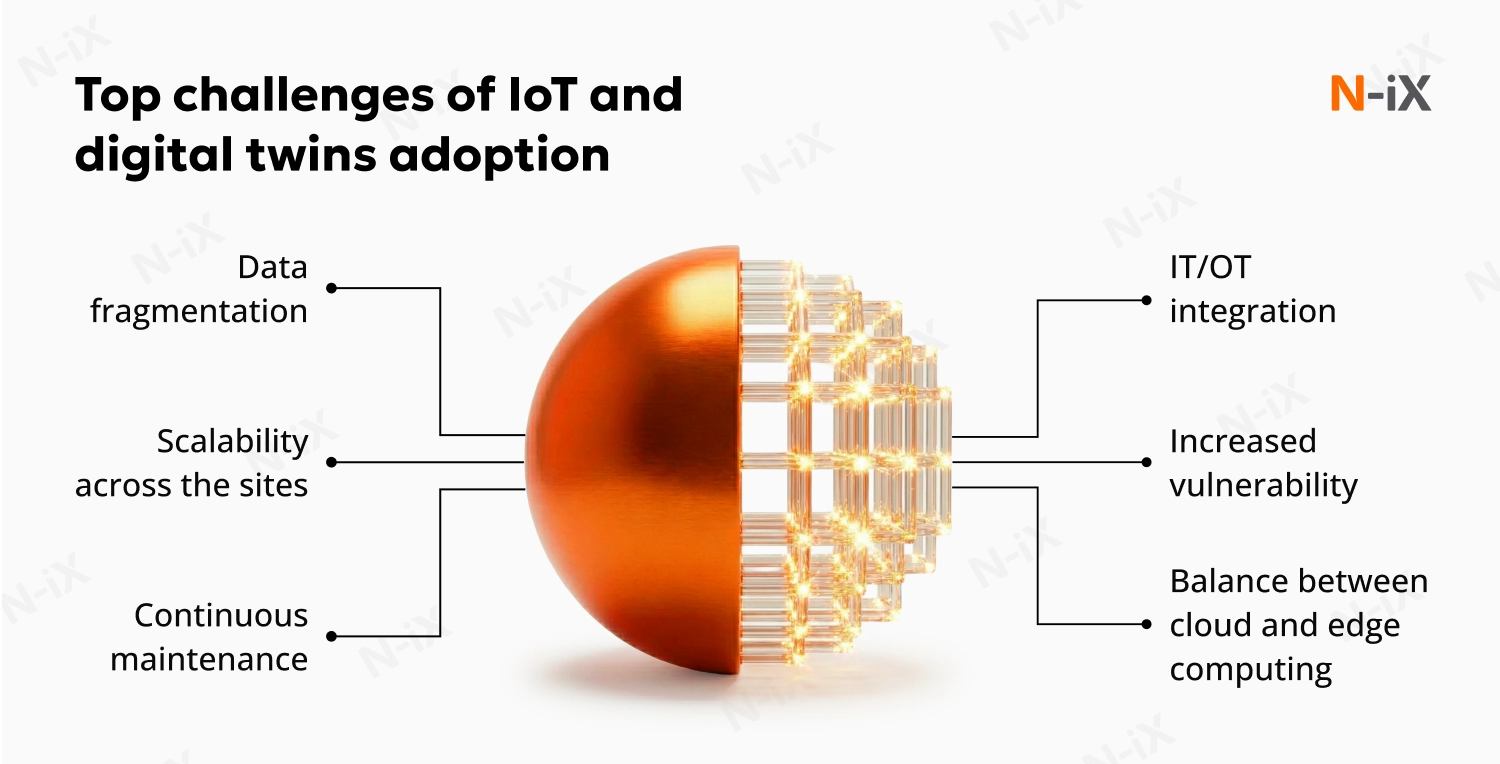

Top challenges of digital twins and IoT adoption (and how to solve them

While global leaders like DHL, Shell, Hymer, BMW, and Airbus prove that IoT and digital twins are no longer experimental, scaling these technologies across an organization is far from simple. Every industry adopting them faces its own set of roadblocks when connecting physical assets to real-time digital replicas. And whether you're starting with a single asset twin or planning full process-level digitalization, addressing these challenges early is critical for long-term success. Below are the key issues organizations encounter, along with practical ways to overcome them.

1. Fragmented, inconsistent, or low-quality data

IoT sensors generate massive amounts of data, but manufacturing lines, warehouses, power assets, or vehicle systems often rely on legacy equipment or siloed data sources. When time-series data, CAD models, PLC outputs, or environmental readings don't align, digital twins cannot accurately mirror the physical environment.

Industry example: In manufacturing, vibration and temperature sensors may stream data every second, while MES systems update batch information every hour, causing misalignment in the asset twin. In logistics, forklift telematics data may not match WMS events in real time.

N-iX's approach: Our strong data expertise and over 200 data specialists help enterprises build normalized data layers that unify sensor data, equipment outputs, engineering models, and enterprise systems. We implement validation and cleansing pipelines, metadata management, and standardized schemas, ensuring every digital twin is powered by accurate, consistent, real-time data.

2. Integrating IoT with OT/IT systems

Industrial IoT must connect with PLCs, SCADA, MES, ERP, PLM, and safety systems. These systems use different protocols, data formats, and lifecycles. Without integration, the twin cannot contextualize sensor data or exchange insights back into operations.

Industry example: In energy and utilities, integrating turbine sensors with asset management systems (CMMS) is essential for predictive maintenance. In automotive plants, digital twins must read robot telemetry while synchronizing with PLM and tooling instructions.

N-iX's approach: We design robust integration architectures that bridge industrial protocols (OPC UA, Modbus, CAN bus), enterprise APIs, and cloud IoT platforms. Our engineers build connectors that align operational data with digital twin engines, enabling end-to-end visibility across OT and IT.

Learn these top tips on how to approach IT/OT convergence

3. Scaling beyond pilots

Most organizations successfully deploy a pilot twin (one line, one turbine, one warehouse zone).

Scaling beyond pilot projects poses challenges in bandwidth, computing resources, governance, and standardization. It also requires aligning organizational processes and team workflows to manage the increasing complexity of digital twin systems across multiple sites or assets.

Industry example: A logistics company may start with a digital twin of a single warehouse but struggle to replicate it across 20 global sites with different equipment vendors. A manufacturer may build a line twin but face data volume spikes when expanding to system- or process-level twins.

N-iX's approach: N-iX helps design cloud-ready, event-driven architectures that support high-frequency IoT workloads at scale. We establish repeatable templates, shared data models, and governance frameworks so organizations can replicate digital twin deployments consistently across locations.

4. Security gaps across devices, networks, and models

Every connected device broadens the attack surface. IoT devices may lack adequate security measures, while digital twins often store sensitive engineering data. Combined with cross-system integrations, these factors create potential security vulnerabilities that need to be addressed across all levels of the IoT-digital twin ecosystem.

Industry example: In energy, unauthorized access to turbine telemetry could affect grid stability. In automotive manufacturing, compromising a virtual production line simulation could misconfigure real-world processes.

N-iX's approach: Our teams implement secure-by-design principles, device identity management, encrypted communication, network segmentation, threat monitoring, and role-based access for engineering models. With our IoT security services, we ensure every layer of the IoT-digital twin ecosystem meets security and compliance requirements.

5. Maintaining model accuracy over time

Digital twins evolve. Equipment ages, processes change, new sensors are added, and models drift. Without continuous calibration and version control, the twin becomes outdated, and insights become unreliable.

Industry example: In aerospace, maintenance schedules depend on precise model updates informed by flight hours, wear profiles, and sensor telemetry. In chemical manufacturing, process twins must adjust when recipes or environmental conditions change.

N-iX's approach: N-iX provides lifecycle management for digital twins, including automating model updates, retraining ML models, tracking version history, and synchronizing schema changes. This ensures the virtual replica always reflects real-world conditions.

6. Choosing the right balance between cloud and edge computing

Digital twins require both high-frequency IoT data and scalable computation. But deciding what runs at the edge (close to the asset) and what runs in the cloud becomes a strategic tradeoff. Too much cloud processing introduces latency and bandwidth costs; too much edge processing limits analytical depth and central coordination. Finding the right balance is especially difficult in industries with remote sites, constrained connectivity, or real-time safety requirements.

Industry example: In oil and gas, offshore platforms cannot rely solely on cloud connectivity for mission-critical decisions; edge processing must handle real-time alerts and equipment behavior simulations. In automotive manufacturing, high-volume robot telemetry is often preprocessed at the edge before being fed to cloud-based systems or process twins.

N-iX's approach: N-iX helps organizations design hybrid architectures that distribute workloads intelligently, i.e., processing time-critical data at the edge while using cloud environments for heavy simulations, multi-site coordination, and long-term analytics. We assess latency requirements, bandwidth constraints, and computational demands to design the optimal balance between cloud and edge for each use case. In addition, we have over 400 cloud experts to help you with cloud engineering tasks.

Final thoughts

Having a digital replica of parts, products, and processes is proven useful across various industries, including manufacturing, automotive, aerospace, and others. But powering them with real-time data from IoT-connected sensors opens even more capabilities for managing and experimenting with assets and processes.

With more businesses planning to scale their IoT and digital twin systems across sites and improve operations, it's important to keep up with this trend. The companies often seek expert guidance to navigate complex integrations and ensure scalable, secure solutions.

N-iX brings 23 years of experience helping businesses with software development to improve efficiency, innovation, and revenue growth. With a team of 2,400 professionals across multiple regions and expertise in cloud solutions, industrial IoT development, data analytics, AI, connected device engineering, and other technologies, we help you design and integrate tailored solutions that meet your specific needs. Whether through Staff Augmentation, a Managed Team, or Custom Solution Development, N-iX helps businesses tackle the technical complexities of IoT and digital twin integration, ensuring seamless implementation, scaling, and optimization of their digital transformation journey.

Sources:

- Top 10 industrial technology trends-as seen at Hannover Messe 2025 | IoT Analytics

- Emerging Tech: Revenue Opportunity Projection of Simulation Digital Twins | Gartner

- Digital twins: The next frontier of factory optimization | McKinsey

- DHL Supply Chain partners Tetra Pak to implement its first digital twin warehouse in Asia Pacific | DHL

- With the Nyhamna onshore facility paving the way, Norske Shell takes digital twin technology subsea | Shell

- Recreational vehicle manufacturer digitalizes concept of camper van | Siemens

- This is how DIGITAL the BMW iFACTORY is | BMW Group

- BMW Group scales Virtual Factory | BMW Group

- Digital Twins: Accelerating aerospace innovation from design to operations | Airbus

FAQ

1. What's the difference between IoT vs digital twins?

IoT (Internet of Things) refers to the network of connected physical devices, sensors, and equipment that collect and transmit real-time data. Digital twins are virtual models or replicas of physical assets, systems, or processes, created from various data sources, including IoT sensors. While IoT focuses on gathering and transmitting data, digital twins use this data to simulate, analyze, and predict behaviors, helping businesses optimize operations and improve decision-making.

2. What are the 4 types of digital twins?

The four main types of digital twins are component twins, asset twins, system twins, and process twins. A component twin models individual parts or components of an asset, tracking their performance in real-time. An asset twin represents the entire asset, like a machine or vehicle, providing insights into its operations and maintenance needs. A system twin aggregates data from multiple assets or components within a system, such as a production line, to optimize performance. A process twin simulates and monitors entire workflows or business processes, integrating data from multiple systems to improve operational efficiency at scale.

3. What is a common application of digital twins in IoT?

A common application of digital twins in IoT is predictive maintenance, where real-time data from IoT sensors is used to monitor equipment health and predict potential failures. It helps reduce downtime and optimize maintenance schedules across industries such as manufacturing, energy, and transportation. Beyond maintenance, digital twins are also used in asset optimization, product design, and process improvement, providing real-time insights and driving efficiency in various sectors.

4. What are IoT and digital twins in the enterprise context?

In an enterprise context, IoT refers to networks of connected sensors, devices, and machines that capture and transmit real-time data, enabling intelligent monitoring, control, and automation of operations. Digital twins use this data to create virtual replicas of physical assets, systems, or processes, allowing businesses to simulate, analyze, and optimize operations. In industries such as manufacturing, energy, transportation, and smart cities, these technologies help improve operational efficiency, enhance decision-making, and provide deeper insights into the performance of physical assets and workflows.

5. Can you use IoT without a digital twin and vice versa?

Yes, IoT can be used without a digital twin. IoT provides real-time data collection and monitoring capabilities for physical assets, even in the absence of a digital model. However, a digital twin without IoT data would lack real-time insights and predictive capabilities, reducing its effectiveness. While both technologies can be used independently, their combined application delivers greater value, enabling enterprises to optimize operations, enhance forecasting, and make data-driven decisions across the entire lifecycle of assets."

6. Do digital twins always require AI?

Not all digital twins require AI. Early digital twins often rely on deterministic, rule-based models to replicate asset behaviors based on established physical principles. However, as the need for predictive and prescriptive insights grows, AI and machine learning (ML) become essential. AI-driven digital twins enable advanced simulations, real-time optimization, and predictive maintenance at scale, making them crucial for industries with complex systems, such as manufacturing, healthcare, and energy.

7. How do digital twins relate to digital threads or simulations?

A digital thread is a continuous flow of data throughout the lifecycle of a product or process, ensuring that all information remains connected and accessible. Simulations are typically static representations used for testing or visualizing specific conditions. A digital twin is a dynamic model that integrates live data from IoT sensors, enabling ongoing simulation and real-time decision-making. Unlike traditional simulations, digital twins evolve in real time based on data inputs, creating a live connection to the digital thread that supports continuous analysis and optimization.

Have a question?

Speak to an expert