By 2027, half of all companies with warehouse operations will replace traditional scanning-based cycle-counting processes with AI-enabled vision systems [1]. Statista projects that the global computer vision market will reach $29,88B in 2025 and is expected to grow to $72,66B by 2031 [2].

With many projects emerging in this field, enterprises need a reliable image processing and computer vision development services provider. Success depends on integrating preprocessing, governance, and deployment into existing workflows, along with a solid understanding of enterprise business processes.

For instance, there are multiple ways to design such a project depending on the industry and business goals. Therefore, it is essential to learn the difference between computer vision vs image processing, how they work together in practice, and where each technology delivers the most value.

What is image processing?

Image processing improves the quality and utility of visual inputs so people or downstream tools can rely on them. Typical goals include denoising, deblurring, contrast correction, and perspective normalization so that optical character recognition (OCR), barcode readers, or clinicians work with cleaner images.

What is computer vision?

Computer vision interprets what is in the scene and turns it into actionable signals. The focus is on meaning and operational context, such as detecting a defect, verifying personal protective equipment (PPE), counting inventory, or flagging unsafe behavior. These outputs guide the next step in a manufacturing execution system (MES), warehouse management system (WMS), or security workflow.

Discover the best computer vision use cases by industry

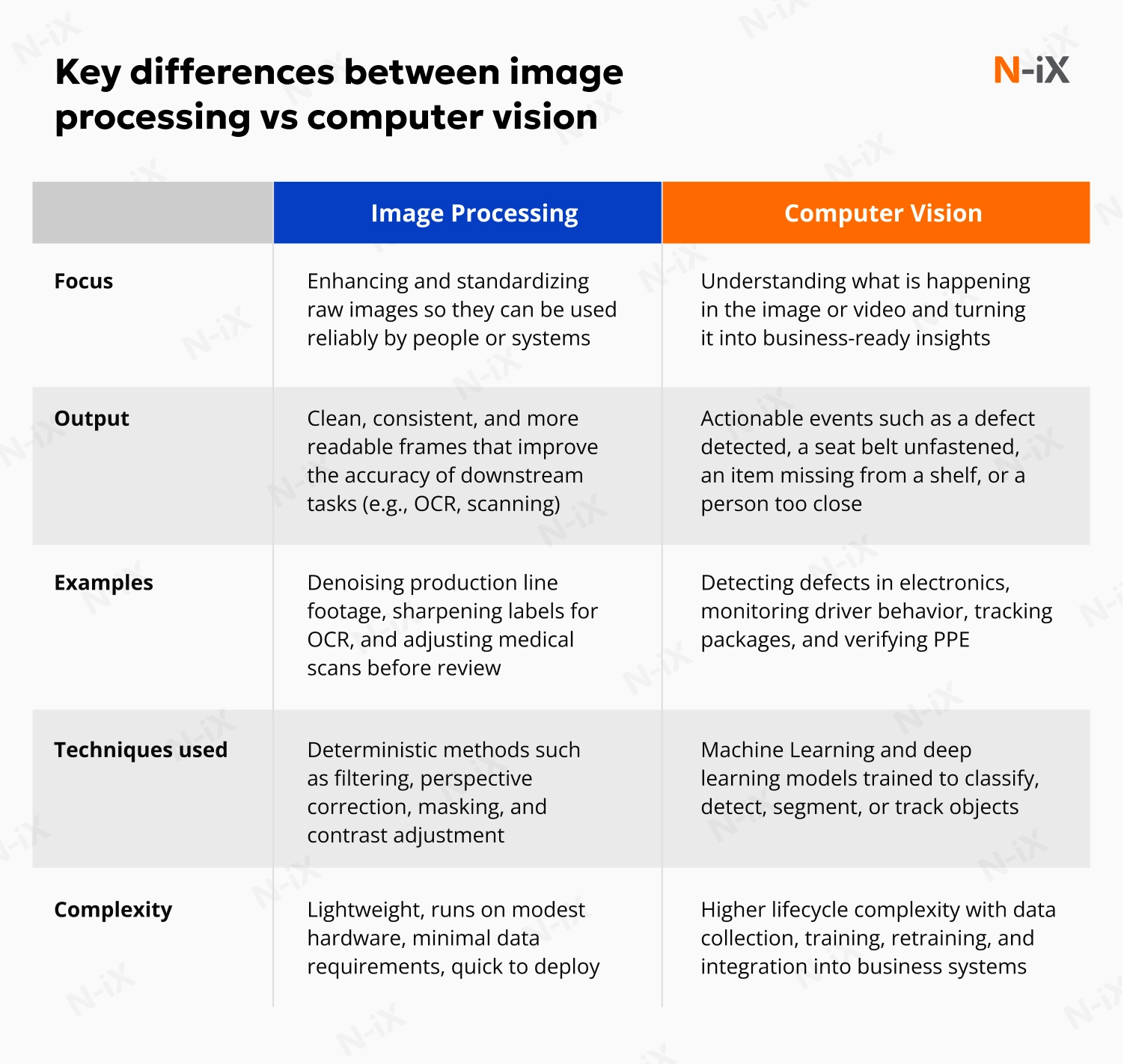

Image processing vs computer vision: Key differences

Understanding the difference between computer vision vs image processing is essential for decision-makers who are considering automation projects. Although the two terms are often used together, they serve different purposes: image processing prepares and enhances visual data, while computer vision interprets it and turns it into business actions. Let’s review their differences in more detail.

Focus

Image processing concentrates on pixel-level improvement in stable environments with fixed cameras and repeatable scenes. The aim is consistent inputs that reduce manual effort and cut variance in downstream tasks.

Computer vision focuses on content and context under variable conditions. Lighting changes, objects move, backgrounds are cluttered, and camera angles shift, so the system must generalize across sites and edge cases while maintaining accuracy.

Output

Image processing delivers enhanced frames, segmentation masks, or numeric measurements that a person or a simple rule can consume. Success is usually tracked with image-quality metrics and uplift in the target task, such as higher OCR accuracy after denoising.

Computer vision emits higher-level signals: detections, classifications, segmentations, object tracks, and event alerts. Performance is measured with precision and recall, false-positive and false-negative rates, latency, and throughput aligned to service-level objectives.

Examples

Image processing stabilizes point-of-sale footage for OCR, corrects perspective during document capture, enhances radiology images before specialist review, and sharpens shelf photos to improve label reading.

Computer vision implementation helps detect surface defects on a production line, verify seat-belt use, measure shelf availability, count pallets and boxes, and track worker-vehicle proximity. It also supports logistics tasks such as correctly classifying stock-keeping units (SKUs) during product returns, ensuring exceptions are routed to the right process.

Techniques used

Image processing relies on deterministic methods such as filtering, geometric transforms, histogram equalization, and morphological operations. Advantages include predictability, modest computing needs, and short deployment cycles with minimal data preparation.

Computer vision learns patterns from labeled data using Machine Learning and deep learning. The approach is more resilient to variation and achieves higher accuracy on complex tasks. Still, it also introduces data labeling, model training, regular updates, and often the need for GPUs (graphics processing units) or accelerated edge hardware.

Complexity

Image processing is lighter to run and maintain. Data needs are limited, acceptance criteria are straightforward, and standard CPU-class hardware or low-power edge devices are usually sufficient, which keeps costs and timelines tight.

Computer vision requires a more complex lifecycle. Teams curate datasets, label examples, train and validate models, monitor performance drift, and operate deployments on the edge or in the cloud. Budgets should account for data operations, periodic retraining, governance, and system integration efforts.

As you can see from comparing these technologies, they address different layers of the same challenge: one ensures the data is usable, the other turns it into insights and actions. Looking at computer vision vs image processing in this way helps decision-makers understand why both are usually combined to deliver reliable enterprise results.

Read more: Machine vision vs computer vision

How do computer vision and image processing work together?

Image processing prepares visual data, while computer vision interprets it and triggers actions. Teams combine them in a single pipeline to raise accuracy, cut false alarms, and keep latency low. Preprocessing stabilizes inputs across lighting, motion, and sensor noise so models receive consistent signals.

Apply AI for image recognition at enterprise scale—get the guide!

Success!

Computer vision then converts those signals into events that downstream systems can trust, which shortens the time from frame to decision and reduces operator load. The results are: fewer edge-case failures, clearer thresholds for action, and faster time from frame to decision.

One example of combining computer vision and image processing is a CV-powered traffic management solution delivered by N-iX for a global provider of intelligent transport systems. Our team developed two computer vision models to monitor driver behavior in real time under such conditions as sun glare on the windshield, different camera locations, and a lack of lighting. One of the models detected seat belt violations, and another identified distracted driving. The solution achieved 88% accuracy in detecting seat belt use and 91% in spotting distracted behavior, all running at 30 frames per second. The successful validation enabled regulatory approval and opened the path for broader market rollout.

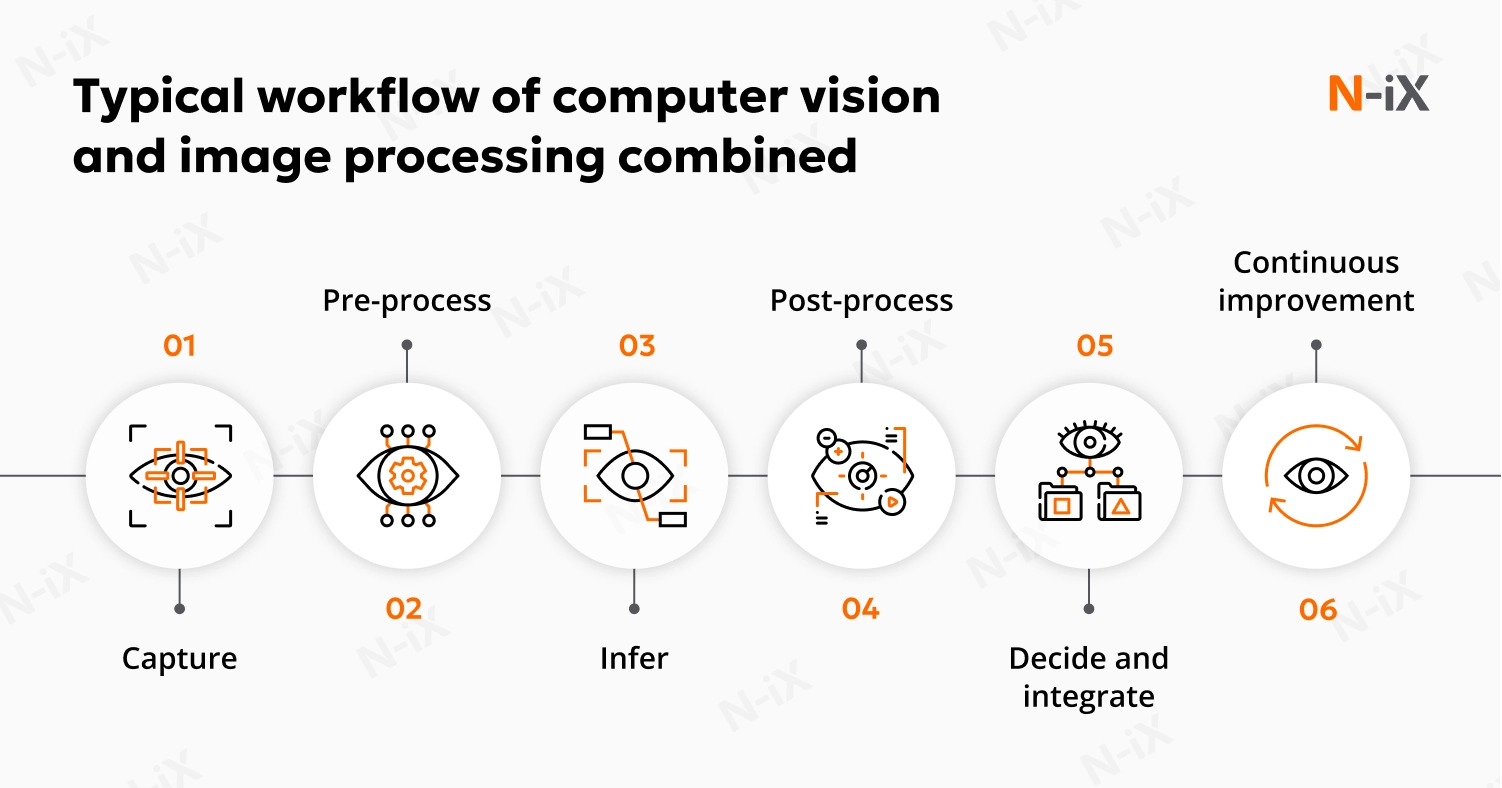

Here is how a typical workflow of combined computer vision and image processing looks:

- Capture: Cameras or scanners collect frames or video under real operating conditions.

- Pre-process (image processing): The system denoises and deblurs images, corrects exposure and perspective, normalizes colors, crops regions of interest, and masks sensitive content. The result is a clean, consistent image ready for further analysis.

- Infer (computer vision): Models detect, classify, segment, and track objects or events such as defects, missing labels, absent protective equipment, or unsafe proximity.

- Post-process: The pipeline smooths jitter across frames, merges tracks, applies business thresholds, and attaches confidence scores to the results.

- Decide and integrate: Validated events are sent to manufacturing execution systems (MES), warehouse management systems (WMS), ticketing platforms, or alerting tools. Dashboards are updated automatically, and operators receive tasks when confidence scores are borderline.

- Continuous improvement: The pipeline logs data and outcomes, captures edge cases for labeling, retrains models, and rolls out updates. Monitoring ensures precision, recall, and error rates remain within service levels, while latency and throughput stay under control.

Learn more about computer vision in the supply chain

Conclusion

Selecting the right approach between computer vision vs image processing is less about the technology itself and more about aligning capabilities with business needs. Leaders must weigh how predictable the operating conditions are, what level of accuracy is required, and how complex the integration will be before deciding how far to scale.

- Image processing is best suited for tasks like OCR or barcode scanning, where enhancing and standardizing inputs is enough.

- Computer vision is required when systems interpret complex or variable scenes, generalize across conditions, or drive real-time automated actions.

- Combined pipelines are the enterprise-scale standard, where preprocessing ensures consistency and models deliver actionable outputs to business systems.

Making these distinctions early helps organizations avoid both extremes: over-engineering and under-investing, ensuring that vision projects translate into measurable results.

If you are considering such an initiative, choosing the right partner is just as important as selecting the right technology. N-iX is a global software development company with deep expertise in AI and data, offering computer vision development services that cover the whole cycle from preprocessing and model design to integration and long-term support. With more than 200 data experts among the team of 2,400 specialists across engineering, cloud, and other domains, N-iX helps enterprises decide between computer vision vs image processing approaches, align them with business goals, and deliver scalable solutions that create lasting value.

References

1. Gartner. Gartner Predicts Half of Companies With Warehouse Operations Will Leverage AI-Enabled Vision Systems by 2027.

2. Statista. Computer Vision - Worldwide

Have a question?

Speak to an expert