Quality inspection is becoming a growing bottleneck for manufacturers operating at scale. As product complexity rises, production volumes grow, and defect tolerance narrows, manual and rule-based inspection methods fall short. That, in turn, results in missed defects, inconsistent assessments, and delayed detection. For businesses, it means increased costs, risks, and negative brand exposure.

Computer vision replaces manual inspection with real-time visual defect detection. It automates quality checks across products and components, bringing consistency, speed, and accuracy to quality control.

In this article, we explore how computer vision defect detection works, where it delivers business value, and how to avoid the implementation pitfalls that prevent systems from scaling reliably.

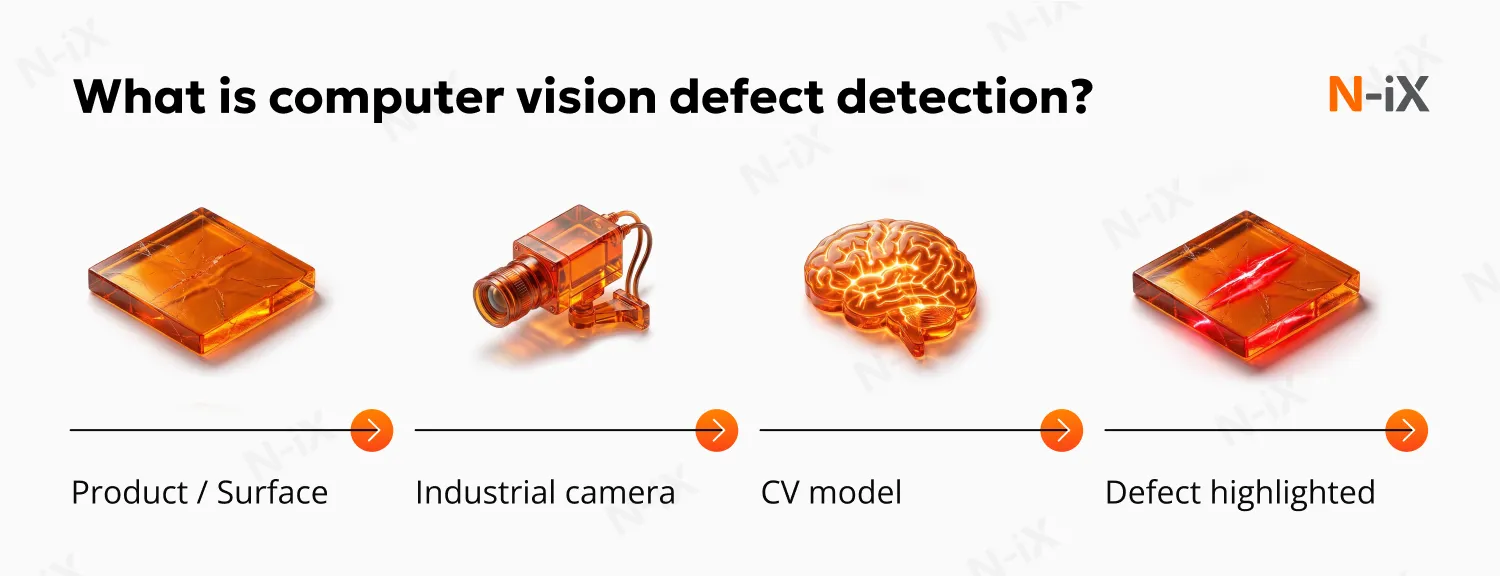

What is computer vision defect detection?

Computer vision defect detection uses AI models to automatically identify product defects by analyzing images or videos captured during manufacturing. High-resolution cameras installed on production lines continuously scan components and finished goods, while trained computer vision models detect anomalies such as:

- Surface defects (scratches, dents, and cracks)

- Dimensional or shape deviations

- Missing, misaligned, or incorrectly assembled components

- Color, texture, or coating inconsistencies

- Contamination or foreign objects

At a business level, computer vision replaces manual inspection with automated, high-precision visual control. It enables continuous inspection at production speed, checking every unit and eliminating variability from fatigue or subjective judgment.

Modern computer vision relies on machine learning and deep learning models that adapt to real-world conditions. These models remain reliable despite changes in lighting, materials, or product appearance, making them suitable for dynamic production environments.

Key benefits include:

- Earlier defect detection that prevents downstream failures and recalls

- Lower costs from reduced scrap, rework, and returns

- More predictable quality and operational performance

- Stronger brand protection through consistent product standards

By delivering higher accuracy, speed, and consistency at scale than human inspection, computer vision has become a foundational capability for modern quality control.

Get the guide to computer vision—learn how to implement it effectively!

Success!

How defect detection works

Image acquisition

Production-line cameras and lighting systems capture images of every unit as it moves through the line. The setup maintains full throughput while providing complete visual coverage. Engineers tune camera placement, angles, and lighting to highlight defect-relevant details while maintaining consistent image quality at speed.

Data preparation for real-world conditions

Inspection pipelines prepare visual data to reflect real operating conditions rather than controlled test environments. They compensate for lighting fluctuations, surface reflections, background noise, and material variation between batches. This step helps maintain detection accuracy as production conditions evolve.

Defect identification and severity assessment

Computer vision models analyze visual patterns to identify anomalies and known defect types. Instead of relying on binary pass/fail rules, the models classify defects by severity and operational impact. This allows teams to separate cosmetic deviations from functional risks and critical quality failures.

Automated response and operational feedback

Detection results trigger immediate actions within production workflows, rejecting faulty items, routing products for rework, or alerting operators. At the same time, inspection data accumulates across shifts and lines, exposing defect patterns and process bottlenecks. Teams use these insights to improve upstream processes and reduce recurring quality issues.

Business value of computer vision defect detection

Computer vision for defect detection transforms quality control into a scalable, data-driven capability. By enabling automated inspection across production, organizations achieve a level of consistency and control unattainable with manual or rule‑based approaches.

The value is not higher accuracy alone; it is the ability to sustain quality, efficiency, and risk control simultaneously as operational complexity grows.

Predictable quality at scale

Every unit is evaluated against the same quality standards, independent of volume, shift patterns, or human variability. This predictability becomes critical as operations scale, product complexity increases, or quality requirements tighten.

Lower quality-related costs

Early defect detection prevents quality issues from compounding across operational stages. By reducing scrap, rework, downstream failures, and customer returns, organizations protect margins while avoiding the hidden costs of late-stage remediation.

Operational stability and efficiency

Automated inspection removes inspection bottlenecks and enables continuous operation without fatigue or delays. Quality checks keep pace with throughput, supporting smoother operations and more reliable delivery timelines.

Reduced risk and stronger compliance

Consistent defect detection protects brand reputation and helps ensure regulatory and safety compliance by minimizing the likelihood of defects reaching customers.

Key components of computer vision defect detection

Behind every effective defect detection system is a tightly integrated set of components that delivers reliable, real-time quality control at scale.

|

Component |

Role in defect detection |

The impact |

|

Visual capture infrastructure |

Industrial cameras and optimized lighting capture consistent, high-quality visual data. |

Ensures reliable detection of subtle defects despite environmental variability. |

|

AI-powered inspection software |

Computer vision models analyze visual data to identify and classify defects with high precision. |

Reduces false positives, adapts to real conditions, and minimizes manual inspection effort. |

|

Decision and response layer |

Defects are classified by severity and automatically linked to predefined actions such as rejection, alerts, or process intervention. |

Prevents quality issues from escalating and accelerates corrective action. |

|

Scalable processing and connectivity |

Real‑time inspection with seamless connectivity to operations systems. |

Maintains inspection speed at scale and embeds quality control into existing workflows. |

Read more about computer vision quality inspection: How AI improves accuracy and compliance

Computer vision-based defect detection delivers value only when designed for real operating conditions. Implementation expertise turns models and cameras into a dependable quality-control capability that performs consistently, scales predictably, and integrates cleanly into existing operations.

Applications across industries

Computer vision defect detection is already deployed in production environments across multiple industries where inspection accuracy, speed, and consistency directly affect revenue, safety, and brand trust:

Automotive

The automotive sector uses computer vision to detect surface and assembly defects at production-line speed, where manual inspection is no longer viable. Advanced camera systems combined with AI models identify dents, scratches, and assembly inconsistencies at a sub-millimeter scale, achieving detection accuracy above 95%.

Mercedes-Benz's manufacturing facility in Spain employs comparable deflectometry-based inspection techniques, achieving comparable precision while reducing the false positives that plague traditional automated systems. These CV systems operate continuously without fatigue, maintaining inspection consistency across all production shifts while a human inspector's detection accuracy degrades over an 8-hour shift.

Electronics

In PCB and electronics manufacturing, AI‑driven optical inspection processes thousands of images per minute and finds missing components (e.g., solder joint failures and micro‑cracks) invisible to human inspection. AI-driven defect detection frameworks using convolutional neural networks achieve high recognition rates, significantly reduce inspection time, improve mean average precision metrics, and decrease false-detection rates that lead to rework.

The latest implementation uses microchip FPGA technology to scan each board in seconds, with the system automatically identifying missing components and surface defects by overlaying bounding boxes directly on PCB images, eliminating manual inspection.

Food & beverage

The industry deploys computer vision to identify foreign objects, packaging defects, and labeling errors in real time. Modern systems combine visual, spectral, and AI-based analyses to detect contaminants such as metals, plastics, glass, and organic matter with 93-99% accuracy, depending on the application.

These solutions provide automated traceability, audit trails, and immediate line intervention, helping organizations prevent recalls and maintain regulatory compliance.

Textiles & materials

The textile industry historically relied on labor-intensive manual inspection, where inspectors visually examined fabrics for defects such as tears, stains, color mismatches, and weave irregularities. However, this approach achieves only ~70% accuracy, whereas CV-based inspection systems detect a wide range of surface and structural defects at production speeds, achieving accuracy above 90%.

A European textile manufacturer replaced manual fabric comparison with AI-driven visual inspection, using high-resolution imaging and automated classification. The approach reduced operator workload, improved defect detection consistency, and accelerated access to accurate product data, resulting in fewer returns and higher operational efficiency.

Discover more about computer vision in manufacturing

Why computer vision defect detection projects can fail and how N-iX helps

Treating defect detection as a model problem, not a production system

Many teams focus on model accuracy in lab conditions and underestimate the challenges of running computer vision reliably in production environments. Lighting changes, surface reflectivity, camera drift, and throughput constraints quickly erode performance once the system leaves the demo stage.

How N-iX helps: We design defect detection as an end-to-end production system rather than a standalone model. That includes the camera and lighting setup, environmental robustness, edge vs. cloud processing decisions, and validation under real operating conditions rather than curated datasets.

Underestimating data readiness and labeling complexity

Defects are rare by design, which slows data collection and results in highly imbalanced datasets. Inconsistent labeling, missing edge cases, and poor annotation quality lead to models that look accurate on paper but fail in production.

How N-iX helps: We help define a realistic data strategy early, combining transfer learning, targeted data collection, augmentation, and controlled use of synthetic data. We also establish labeling standards and validation processes that align model behavior with real quality thresholds.

Overfitting during pilots and a collapse in production

High accuracy during testing often masks overfitting. Once production conditions shift, new materials, different cameras, seasonal lighting, and models degrade rapidly, leading to false positives or missed defects.

How N-iX helps: We design for generalization from day one: representative validation sets, stress testing, controlled rollout, and retraining pipelines. The goal is stable performance over time, not impressive pilot metrics.

Poor integration into operational workflows

A defect detection system that only flags issues without triggering actions adds friction rather than value. Without integration into quality, production, and reporting workflows, insights arrive too late.

How N-iX helps: We integrate defect detection directly into operational decision flows, linking detection to alerts, rejection logic, reporting, and existing execution or quality systems so defects are acted on immediately, not analyzed after the fact.

Wrapping up

Adopting computer vision for quality inspection is as much a strategic decision as a technical one. These systems must deliver consistent visual precision, adapt to real-world variability, and fit naturally into existing operational workflows. Without reliable data pipelines, production-ready infrastructure, and organizational readiness, even the most accurate models struggle to deliver lasting value. This is why many enterprises turn to partners who can connect computer vision capabilities directly to measurable business outcomes.

With over 23 years of engineering experience, a dedicated team of 200 AI, ML, and data specialists, we help enterprises move from manual inspection to scalable, AI-driven quality assurance. Backed by 2,400 specialists and hands-on delivery across advanced computer vision and AI initiatives, we focus on making defect detection systems not just deployable, but reliable, scalable, and sustainable in real production environments.

Have a question?

Speak to an expert