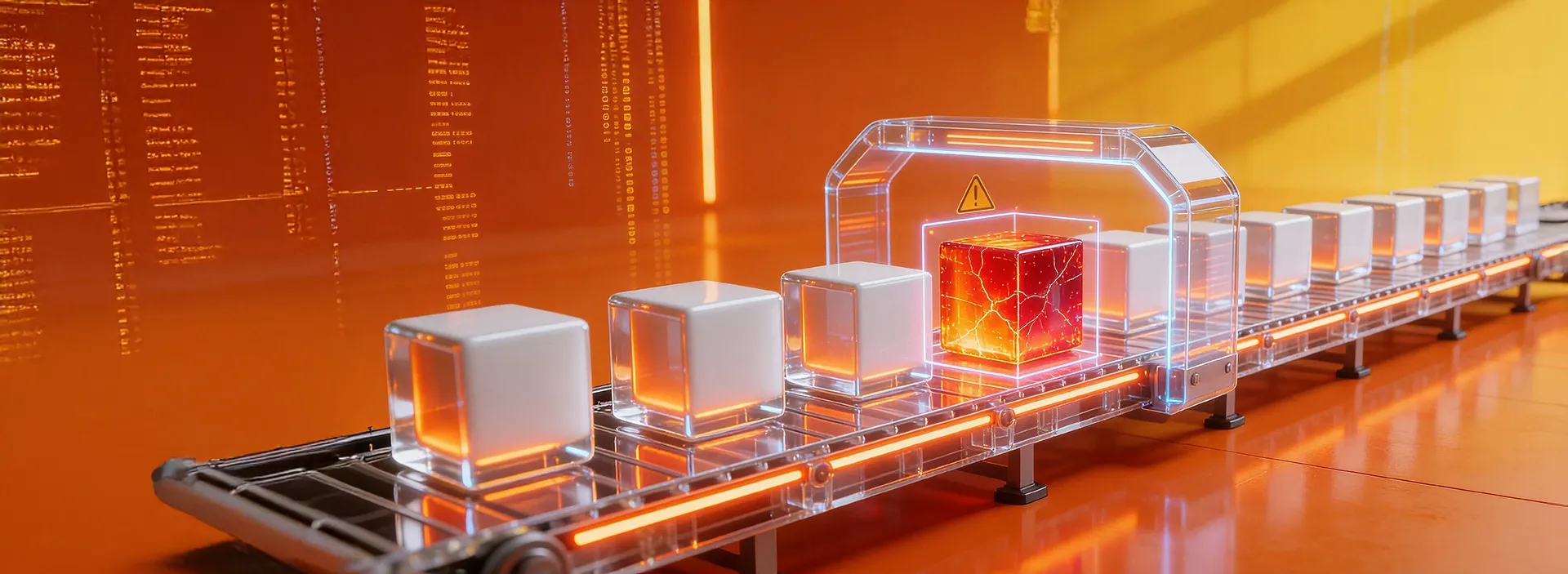

Manufacturing disruptions rarely come without warning; they come with too many warnings to interpret. Modern production environments generate massive volumes of data: temperature, vibration, pressure, energy consumption, and visual inspection feeds. Traditional condition monitoring systems treat these signals in isolation, relying on static thresholds that generate noise while missing early-stage anomalies.

Instead of reacting to predefined limits, anomaly detection continuously learns what normal looks like across assets, processes, and operating conditions. It then highlights deviations that indicate real risk rather than harmless variability.

So what is anomaly detection in manufacturing, where does it create the most value, and what challenges must be addressed to deploy it at scale? Leveraging our expertise in AI and ML system development for industrial enterprises and broader manufacturing software development, we explore how anomaly detection moves from experimentation to operational scale.

How manufacturers know when anomaly detection is necessary

Anomaly detection is the process of identifying unusual patterns or behaviors in data that may indicate potential failures, quality issues, or operational risks.

Traditional monitoring and maintenance approaches work well in stable, low-variability environments. As complexity increases, their limitations become harder to ignore. Manufacturers can benefit from AI-driven anomaly detection when one or several of the following conditions apply:

- Operational variability is increasing: Equipment runs across multiple products, batches, or configurations, making fixed thresholds unreliable.

- Failures or quality issues emerge without clear precursors: Defects, downtime, or performance degradation occur despite adherence to preventive maintenance and SPC controls.

- Small deviations have an outsized impact: Minor process drift can lead to scrap, rework, safety risks, or customer-visible quality issues.

- Data volume exceeds human interpretation: Sensor, vision, and production systems generate more data than teams can analyze in real time.

- Scaling consistency is a priority: Plants, lines, or assets perform differently, and best practices are hard to translate across sites.

In these environments, anomaly detection in manufacturing delivers value not by replacing existing controls, but by complementing them, exposing early signals that traditional methods were never designed to detect.

Understanding anomalies in a manufacturing environment

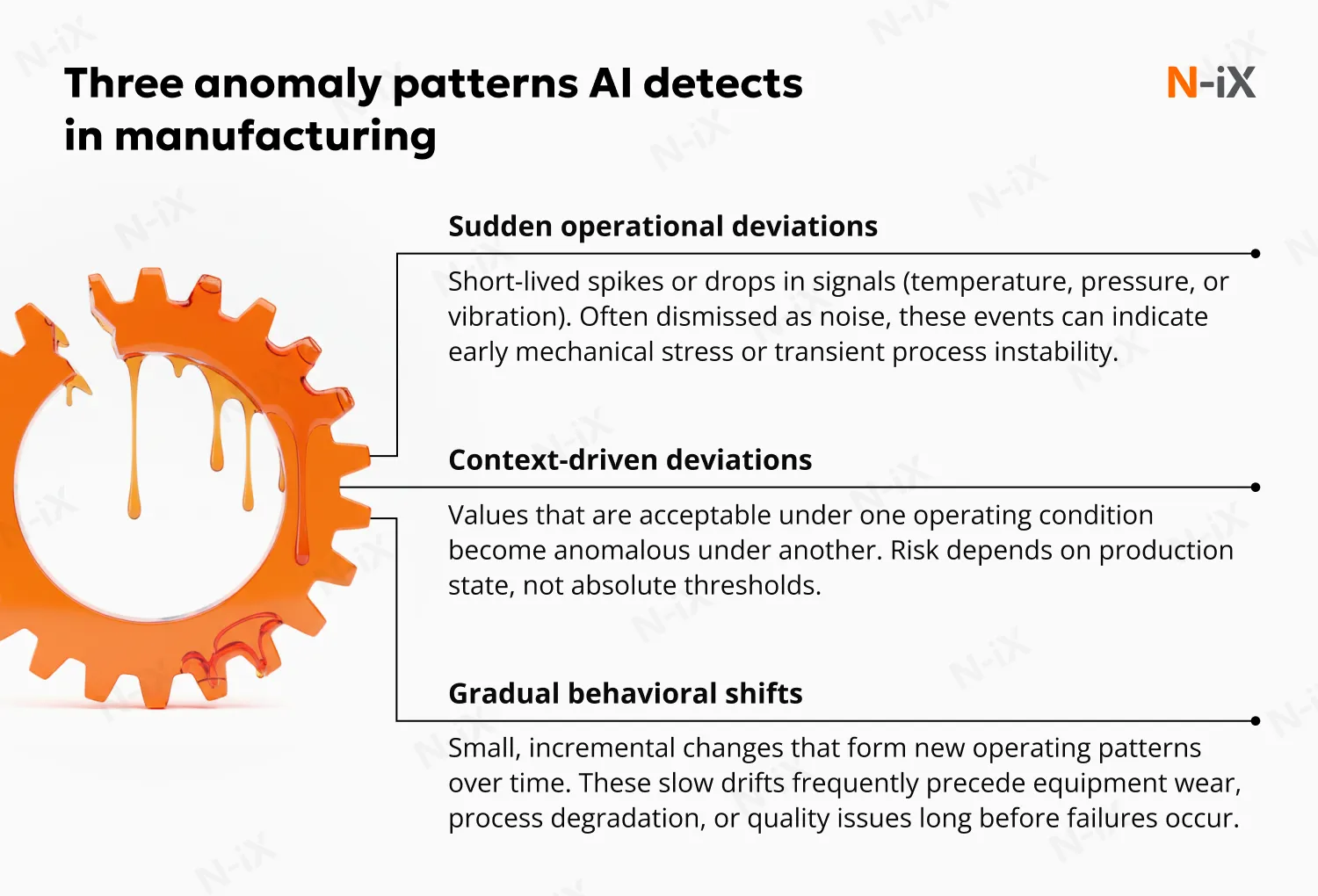

In manufacturing, anomalies rarely appear as obvious failures. They emerge as small deviations that only become meaningful when interpreted in context or observed over time. These early signals are easy to miss with rule-based monitoring, yet they often represent the first signs of process instability, equipment degradation, or quality drift.

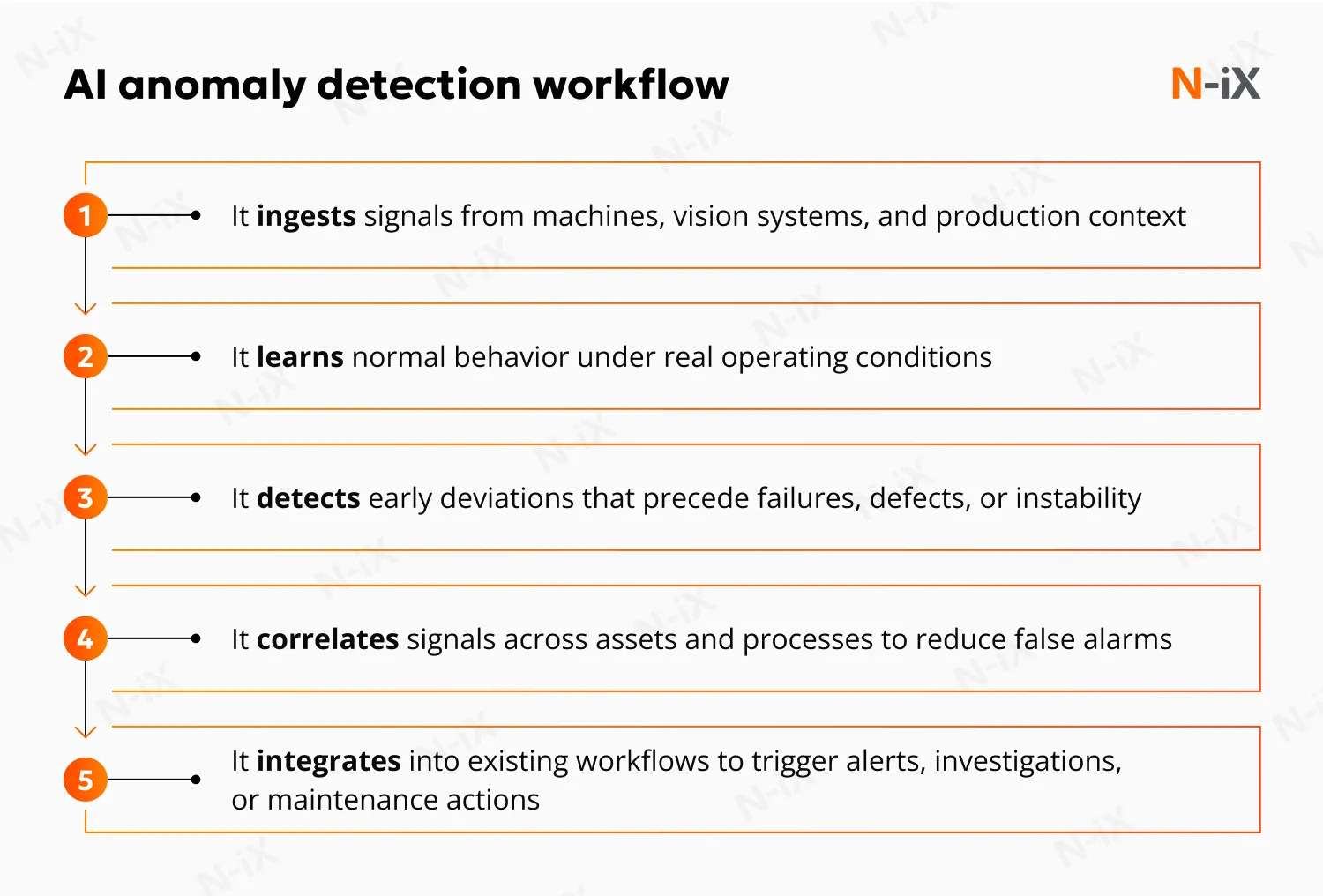

An anomaly detection system using Machine Learning continuously learns normal operational behavior and adapts as production conditions evolve. Rather than relying on fixed thresholds, ML models surface weak signals that precede defects or failures. A typical manufacturing anomaly detection workflow follows an operations-first approach:

- Data ingestion and contextualization of signals from machines, vision systems, and production environments;

- Model training and baseline modeling to establish normal behavior under real operating conditions;

- Deviation identification that surfaces early patterns preceding failures, defects, or process instability;

- Cross-asset signal correlation to minimize false positives and reduce alert fatigue;

- Workflow integration and automated response enablement to trigger alerts, investigations, or maintenance actions within existing operational systems.

Related: Computer vision defect detection: How AI improves quality, accuracy, and scale

Key data sources for manufacturing anomaly detection

|

Data source |

What it reveals |

Why it matters to the business |

|

IoT & sensor data |

Temperature, vibration, pressure, energy consumption |

Detects early equipment degradation before downtime |

|

Vision systems |

Surface defects, misalignments, and dimensional issues |

Reduces scrap, rework, and quality escapes |

|

MES & ERP systems |

Batch context, production plans, resource usage |

Adds operational context and reduces false alarms |

|

SCADA & machine logs |

Machine states, alarms, operator actions |

Accelerates root-cause analysis |

Why traditional maintenance falls short and where anomaly detection is a better option

For decades, manufacturing maintenance strategies have relied on reactive and preventive approaches. While both remain common, their limitations become increasingly visible in data-rich production environments.

The limits of reactive maintenance

Running equipment until failure shifts operations into constant crisis mode:

- Unplanned downtime and delivery disruption;

- Escalating the repair scope from cascading damage;

- Increased safety exposure;

- Higher total cost of repair.

The limits of preventive maintenance

Scheduled maintenance assumes that degradation follows predictable patterns—an assumption that rarely holds. This leads to:

- Over-maintenance, which replaces components too early;

- Fixed intervals, which miss early-life or late-stage failures;

- Planned interventions, which still introduce downtime and risk.

As production systems grow more complex, rigid maintenance models struggle to keep pace with actual equipment behavior.

Why anomaly detection changes the equation

Anomaly detection closes this gap by aligning maintenance decisions with real operational conditions. It enables teams to:

- Identify degradation before failure occurs;

- Intervene based on condition, not assumptions;

- Reduce unnecessary maintenance without increasing risk.

Rather than replacing existing strategies, anomaly detection provides the intelligence layer that enables condition-based and predictive maintenance with better cost control and higher operational confidence.

Key use cases of manufacturing anomaly detection

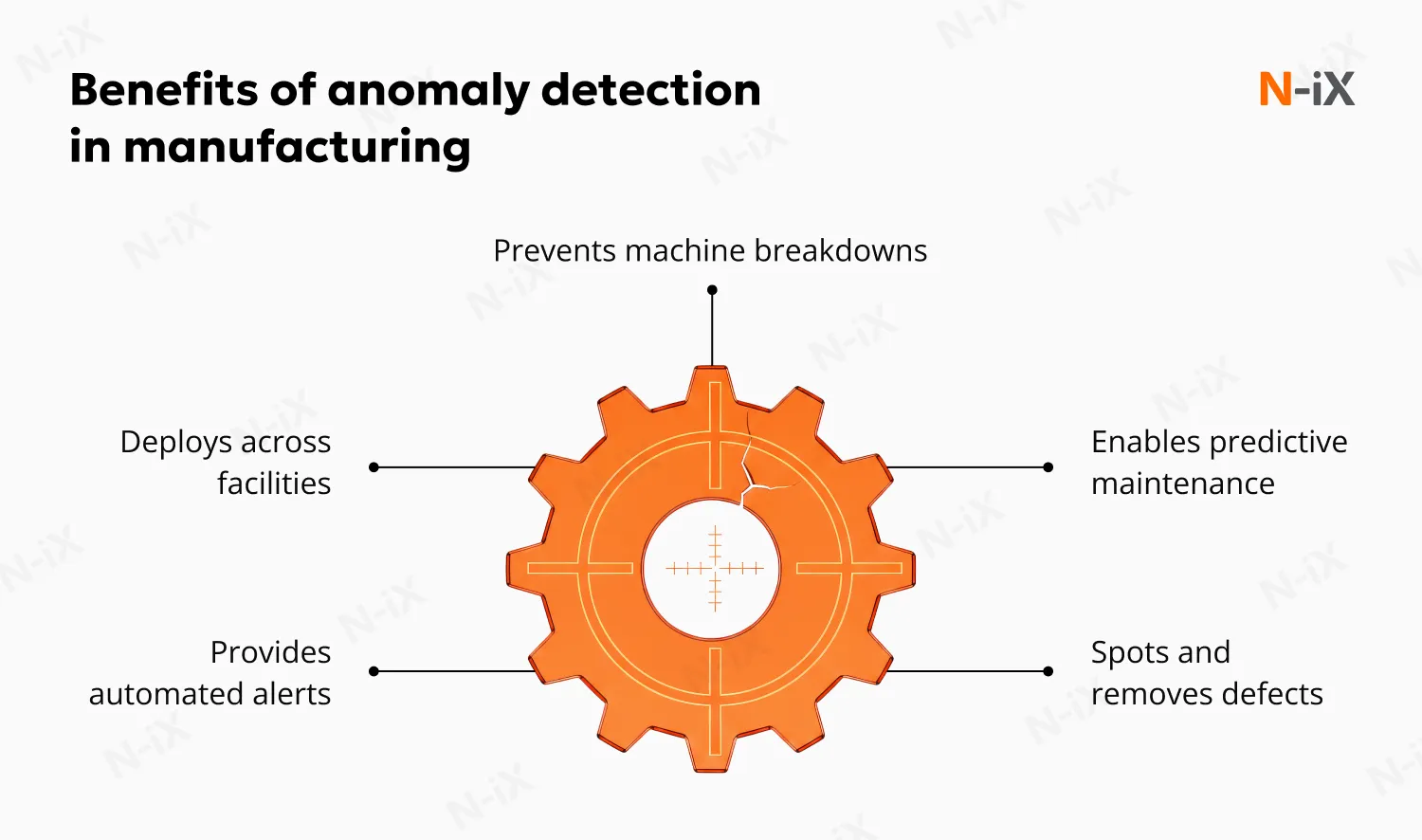

Manufacturing anomaly detection is often introduced as a maintenance tool. In reality, its impact extends far beyond preventing breakdowns. When properly designed and integrated into production systems, it becomes a strategic capability that strengthens reliability, quality, and operational resilience. That value materializes across several operational layers of the production environment, from quality control to asset performance and process stability:

Quality assurance

In modern production environments, manual inspection and rule-based systems struggle to keep pace with throughput and product complexity.

Visual anomaly detection in manufacturing leverages computer vision models to identify surface defects, structural irregularities, misalignments, or packaging inconsistencies in real time. Unlike rule-based inspection systems, AI models evolve with the production environment, detecting new defect signatures as materials, tooling, and workloads change. That translates into lower scrap, fewer rework cycles, reduced warranty risk, and consistent quality performance across plants.

Read more about computer vision quality inspection: How AI improves accuracy and compliance

Process stability

Not every anomaly results in equipment failure. Many operate quietly in the background, reducing yield, extending cycle times, and introducing variability that gradually erodes margins.

By correlating MES data, PLC signals, and sensor streams, anomaly detection ML reveals subtle process deviations that traditional monitoring overlooks: load imbalances, parameter drift, and unstable performance. These signals rarely trigger alarms, yet they shape production economics every day. The impact is structural rather than reactive: improved yield, more stable throughput, lower process variability, and measurable gains in energy efficiency.

Safety and risk mitigation

Manufacturing environments are inherently complex and high-risk. AI anomaly detection strengthens traditional safety systems by identifying abnormal environmental conditions, unsafe behaviors, and unusual equipment interactions before they escalate into incidents.

From monitoring PPE compliance to detecting abnormal pressure or gas readings, anomaly detection expands risk visibility without adding layers of manual oversight. For leadership teams, the outcome is tangible: fewer incidents, lower regulatory exposure, a stronger safety culture, and improved ESG positioning.

Asset reliability and throughput protection

Unplanned downtime is no longer a minor operational issue but a financial risk. In recent research by Fluke Corporation, over 60% of manufacturers reported multiple unplanned outages each week, and the average cost of production halts was estimated at around $1.7M per hour.

Traditional maintenance approaches are difficult to sustain in complex production environments. Reactive models address issues only after a disruption occurs, while preventive schedules rely on predefined intervals that may not align with actual equipment behavior.

Manufacturing anomaly detection changes the model. By continuously analyzing signals from IoT sensors, PLCs, and control systems, anomaly detection learns how equipment behaves under real production conditions. Instead of relying on fixed thresholds, it identifies subtle deviations that signal emerging wear, imbalance, or instability.

Overcoming real-world challenges in manufacturing anomaly detection

Deploying AI anomaly detection in manufacturing is not just a Data Science exercise. It is an operational transformation initiative. And most initiatives fail not because the models are weak, but because the surrounding ecosystem is unprepared. Below are the most common adoption barriers and how N-iX addresses them.

Fragmented data and weak infrastructure

Manufacturing environments are rarely AI-ready. Data is scattered across PLCs, MES, ERP systems, historians, and vision platforms, often siloed, inconsistently labeled, or stored in incompatible formats. Without well-governed, contextualized data pipelines, anomaly detection models generate noise rather than insight.

How N-iX addresses it: We design and implement AI-ready infrastructure that securely connects OT and IT environments at scale. Our teams:

- Build unified data pipelines across legacy and modern systems;

- Implement data governance and quality controls;

- Enable edge-to-cloud architectures where required;

- Ensure security and compliance alignment.

False positives and alert fatigue

Overly sensitive models may flood teams with alerts that obscure true priorities, whereas overly conservative ones can fail to surface meaningful early warnings. Over time, either scenario weakens stakeholder confidence and limits the impact of anomaly detection initiatives. What executives ultimately require is not more visualization, but clearer, context-aware insights that enable informed decision-making.

How N-iX addresses it: We apply a balanced, operations-driven modeling approach that includes:

- Context-aware anomaly detection tuned to production realities;

- Signal correlation across assets to reduce noise;

- Tiered alerting logic aligned with operational severity;

- Human-in-the-loop feedback mechanisms for continuous improvement.

Integration with legacy manufacturing systems

Even the most advanced anomaly detection model creates no value if it operates in isolation. Legacy automation systems, ERP platforms, and maintenance workflows often lack real-time integration capabilities. As a result, insights remain detached from operational processes, limiting the organization’s ability to act on them effectively.

How N-iX addresses it: With deep expertise in industrial integrations, our engineers ensure anomaly detection systems are embedded into existing workflows. We focus not only on model performance, but on seamless orchestration across the production technology stack:

- Integration with MES, CMMS, ERP, and SCADA platforms;

- API and middleware development for legacy environments;

- Automated alert routing into maintenance and quality processes;

- Minimal disruption to ongoing production.

Skills gap and long-term scalability

A successful anomaly detection process requires a blend of expertise in Data Science, ML engineering, and cloud architectures. Few manufacturers have this capability internally.

With a team of over 200 AI and ML engineers and deep experience in AI and enterprise solutions, we operate as an engineering partner that can build, deploy, and scale production-grade anomaly detection systems tailored to manufacturing workflows. Our cross-functional teams combine:

- Wide domain experience;

- Advanced ML and computer vision expertise;

- Cloud and AI infrastructure engineering knowledge;

- MLOps and lifecycle management capabilities.

At N-iX, we guide manufacturers from pilot to enterprise-scale deployment, ensuring models remain accurate, governed, and continuously improved.

From isolated alerts to strategic intelligence

The true business value of manufacturing anomaly detection does not come from detecting “outliers.” It comes from transforming high-volume industrial data into actionable operational intelligence. However, achieving this requires more than deploying a model. It demands expertise in data engineering, industrial systems integration, model calibration, and production-grade AI deployment.

When implemented correctly, anomaly detection becomes embedded into daily decision-making, supporting maintenance teams, quality managers, and plant leadership with continuous, explainable insights. That is where industrial AI expertise determines whether anomaly detection remains a pilot initiative or evolves into a measurable competitive advantage.

FAQ

What is anomaly detection in manufacturing?

Anomaly detection identifies unusual patterns or deviations in data that could indicate potential issues in manufacturing processes. Unlike manual inspections or simple monitoring, anomaly detection using machine learning continuously learns normal operational behavior, surfacing early signals of equipment degradation, quality drift, or safety risks.

What are the anomaly detection challenges in manufacturing?

Implementing anomaly detection in manufacturing can be complex due to fragmented data systems, alert fatigue from false positives, integration with legacy equipment, and the need for domain expertise. N-iX addresses these challenges by designing AI-ready infrastructure, tuning ML models to production realities, embedding insights into existing workflows, and providing cross-functional industry expertise for sustainable, enterprise-scale deployment.

How does anomaly detection differ from traditional statistical process control (SPC) methods?

Traditional SPC uses fixed limits and rules to find problems, which can miss subtle issues. Manufacturing anomaly detection systems, powered by AI and Machine Learning, continuously learn normal behavior and spot early signs of equipment or quality problems, including patterns that traditional methods might overlook.