When warehouses fall behind on throughput, service levels, or cut-off commitments, the cause is rarely a broken process or an underperforming system. More often, it is a sequence of reasonable decisions made with incomplete, outdated, or conflicting information. AI enters warehouse management at this operational fault line. Its role is to support decisions that depend on incomplete, delayed, or conflicting signals.

Used carefully, AI helps warehouses prioritize, sequence, and allocate resources when conditions no longer resemble last quarter’s patterns. But when applied without sufficient grounding, it risks adding another opaque layer to processes that already operate close to their limits.

Many organizations come to N-iX at this stage, when decision-making becomes harder to sustain as complexity increases. Through our AI development services , we focus on applying AI to specific operational decisions, using data already generated by warehouse operations and integrating it into existing systems without disrupting live processes. The sections below examine the use cases of AI in warehouse management, where it delivers measurable improvement, and where it introduces new risks.

What are the key benefits of AI in warehouse management?

Better decisions when conditions change faster than plans

Operational plans in warehouse management are built on assumptions that often become outdated within hours. AI in warehouse management helps close this gap by continuously re-evaluating decisions as conditions evolve. By analyzing live and historical operational signals, orders, inventory movements, workforce availability, and equipment status, AI supports decisions that reflect current constraints. Using Artificial Intelligence in fast-evolving environments improves timing and relevance across planning and execution without requiring constant manual intervention.

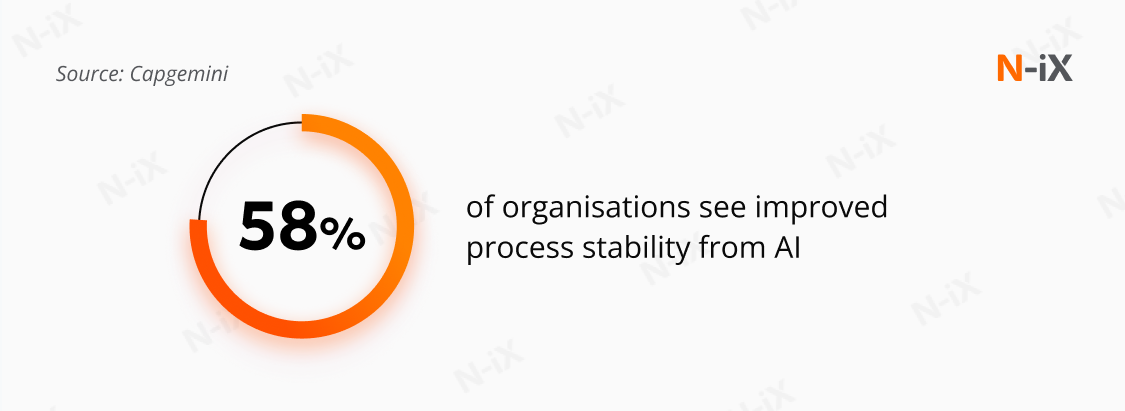

More stable throughput instead of peak-driven optimization

Traditional optimisation often drives warehouse operations toward isolated efficiency peaks, creating downstream congestion. AI shifts the focus from maximum speed to flow stability. By dynamically prioritizing and sequencing work, AI helps warehouses maintain predictable throughput during demand surges, labor shortages, or partial system outages. The result is fewer bottlenecks, less firefighting, and more reliable service levels.

Workforce allocation aligned with real workload patterns

Workforce planning is among the most volatile dimensions of warehouse operations. AI aligns staffing decisions with observed workload distribution across shifts, zones, and task types. Rather than replacing the workforce, AI reduces inefficiencies caused by uneven utilisation, idle capacity in some areas, overload in others, while limiting last-minute schedule changes that strain teams and supervisors.

Earlier detection of disruption and operational risk

Many warehouse disruptions are predictable before they occur, but only if signals are connected early enough. AI identifies emerging risks such as congestion, equipment overload, or backlog growth before they escalate into missed SLAs. AI-driven monitoring also supports:

- Improved safety oversight through real-time hazard detection;

- Enhanced security and loss prevention by identifying anomalous behaviour;

- More consistent quality assurance using automated visual inspection.

AI capabilities tend to influence operational outcomes sequentially, in contrast to in parallel. Across the enterprise warehouse programs we support, the most significant outcomes come from focusing on two or three high-impact decision areas before extending AI into secondary areas such as returns handling, back-office automation, or simulation. When AI is introduced without clear decision ownership or integration into existing workflows, warehouses often experience higher override rates, reduced trust in systems, and slower response during disruption.

Lower operational cost through coordination

The cost impact of AI primarily comes from improved coordination. By reducing rework, unnecessary movement, idle assets, and emergency interventions, AI lowers the hidden costs that accumulate in complex warehouse environments. These gains are often incremental but compound over time, leading to more stable cost structures.

Additional cost impact appears in:

- Automated returns handling that reintegrates inventory faster;

- Back-office automation for billing, documentation, and data extraction;

- Better space utilization through dynamic slotting decisions.

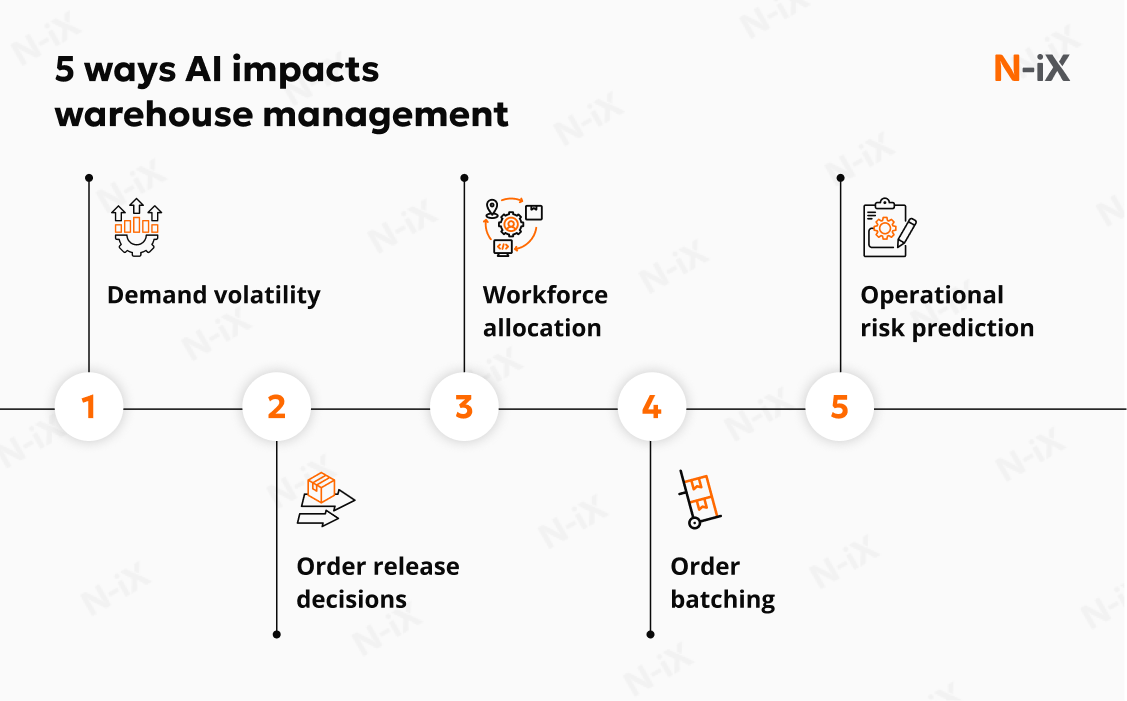

5 AI use cases in warehouse management

1. Demand volatility and inventory positioning

AI improves inventory positioning by modelling demand as a changing probability space. Instead of producing a single expected value, AI inventory management systems estimate demand ranges, confidence intervals, and short-term deviations, then translate that uncertainty into concrete replenishment and placement decisions.

At a technical level, this capability combines short-horizon demand sensing, probabilistic forecasting, and constraint-aware optimisation. Models continuously ingest order inflow, historical sales, seasonality, promotion signals, and lead-time variability. Inventory decisions adjust as these inputs change, allowing stock to be positioned where it absorbs volatility with the least service risk and operational disruption.

What changes in practice is how risk is distributed. High-volume items with stable behaviour require less protection than lower-volume SKUs with erratic demand. AI-driven models explicitly account for this asymmetry, improving service reliability without increasing total inventory levels or relying on broad safety buffers.

In operational terms, these AI applications in warehouse management typically involve

- Demand anticipation across time horizons by combining historical sales, seasonality (for example, holiday or back-to-school patterns), short-term order dynamics, and external signals such as weather or market trends.

- Risk-aware stock level optimization that uses probabilistic models to balance service exposure against working capital across SKUs and locations, reducing both stockouts and excess inventory.

- Risk-adjusted inventory placement that evaluates demand volatility, lead-time variability, and customer proximity to position stock where it delivers the highest service impact.

- Execution-level inventory reliability supported by real-time visibility from WMS events, IoT, or RFID signals, with anomaly detection to surface shrinkage, mis-scans, and flow delays early.

This approach already guides live inventory decisions in complex environments. In a separate engagement focused on inventory management for a UK-based automotive business, N-iX implemented ML-driven analysis to improve stock availability while reducing excess inventory exposure. Rather than relying on static replenishment logic, the solution accounted for demand variability and supply constraints, enabling more informed positioning decisions.

2. Slotting, batching, and order release decisions

Order profiles vary by hour, congestion forms unevenly, and downstream capacity fluctuates. AI models evaluate live conditions and adjust decisions within defined stability limits. These decisions are supported by optimisation models and reinforcement learning techniques that balance competing objectives: travel distance, pick density, downstream capacity, and service cut-offs. Slotting recommendations adapt as velocity shifts, batching logic responds to order overlap, and release timing adjusts based on live execution signals.

Where AI delivers the greatest impact is at the point of release. Evaluating pick load, packing capacity, and shipping constraints before work enters execution reduces congestion without delaying fulfillment. Even small adjustments in release timing often stabilize throughput across the shift.

Dynamic decisioning is most effective when applied selectively. The use of AI in warehouse management improves outcomes where variability is high and decision frequency is manageable, such as release timing or high-velocity SKU placement. Applied too aggressively, especially at the execution level, it can increase instability by introducing excessive change. AI continuously evaluates how order composition, SKU velocity, congestion, and labor distribution interact as conditions evolve.

From an operational standpoint, AI in warehouse management typically evolves into:

- Continuous slotting decisions based on live order profiles, SKU velocity, pick paths, and congestion patterns, with high-demand items positioned closer to packing and shipping zones to protect throughput.

- Order grouping informed by purchase correlation that batches items frequently shipped together, reducing pick travel, improving labor efficiency, and smoothing downstream flow.

- Adaptive order release logic that prioritises urgent orders while intelligently holding or batching lower-priority work based on real-time workload, labor availability, and cut-off pressure.

- Advanced cartonisation models that determine right-sized packaging, minimising handling effort, unused volume, packaging waste, and transportation cost.

During peak windows, even a five-minute delay in release decisions can cascade into missed cut-offs. AI systems adjust release timing earlier in the shift, based on current pick load and downstream capacity, before congestion forms.

3. Labor planning and workforce allocation

AI improves labor planning by modelling workload at a more granular level. Instead of forecasting headcount in aggregate, generative AI in warehouse management evaluates task demand across picking, packing, replenishment, and support functions, accounting for order mix, congestion patterns, and execution constraints. Labor is allocated based on where work is forming, not where it was expected to form hours earlier.

What becomes visible through AI is an early imbalance. Subtle divergences between planned and actual task completion, growing queues in specific zones, or increasing dependency on experienced staff surface before performance degrades. Labor adjustments can be made while options remain available.

Headcount optimization narratives often miss this point. Performance gains usually come from better alignment between labor and workload timing, not from reducing staff numbers. The strongest outcomes of AI in warehouse management typically emerge once baseline productivity stabilises and execution data becomes reliable.

AI-driven labor planning and workforce allocation typically includes:

- Real-time labor redistribution based on live workload signals, enabling proactive repositioning as bottlenecks form during peak periods.

- Workforce demand forecasting that anticipates staffing needs for seasonal and intraday peaks using historical patterns and current order inflow, reducing both understaffing risk and excess labor cost.

- Shift-level execution visibility through AI-assisted control views that consolidate workload, order volume, and equipment status, supporting faster and more consistent supervisory decisions.

- Data-driven task allocation informed by inductive learning models that capture how task mix, congestion, and sequence affect worker performance, helping reduce fatigue and uneven workload distribution.

4. Order batching, wave planning, and release timing

AI treats batching and release timing as adaptive decisions. Instead of releasing work according to fixed schedules, AI in warehouse management evaluates live conditions across picking, packing, and shipping before committing orders to execution.

Release timing carries disproportionate influence. Orders released too early create congestion that propagates downstream; orders released too late compress service windows and increase exception handling. AI models balance these trade-offs by continuously reassessing workload, labor availability, and cut-off constraints, adjusting release decisions accordingly.

Batch composition also becomes more responsive. AI jointly evaluates order overlap, SKU density, and downstream capacity, allowing batches to form in ways that reduce handling friction.

In live operations, AI coordinates picking, batching, and release by:

- Optimized picking sequences that account for product attributes, pick frequency, and real-time order priorities, reducing travel distance and balancing effort across human workers and robots.

- Wave and robot coordination where AI synchronizes multiple order waves and autonomous units, adjusting paths and timing to minimize congestion and collision risk on the warehouse floor.

- Geographic order prioritization that groups orders by destination or delivery corridor, improving truck utilization and consolidation efficiency without compromising service commitments.

- Automated release scheduling that aligns order release volume with live packing and shipping capacity, preventing downstream overload while maintaining steady throughput.

5. Exception detection and operational risk prediction

Exceptions in warehouse operations rarely appear abruptly. They develop as small deviations accumulate across order flow, labor execution, inventory movement, and equipment behaviour. Traditional monitoring identifies these issues only once service levels or throughput are already at risk. AI in warehouse management system enables earlier detection by modelling how operational signals interact over time, not just whether individual thresholds are crossed.

Technically, this capability combines time-series analysis, anomaly detection, and pattern recognition applied to execution-level data. Machine Learning models ingest signals from WMS events, task completion logs, equipment telemetry, and in some environments, computer vision feeds from cameras monitoring floor activity. AI in warehouse management assesses correlated deviations that indicate rising operational risk.

AI-driven exception detection and risk prediction enables:

- Early identification of bottlenecks and congestion by analyzing execution flow patterns before disruption becomes visible on the floor.

- Prediction of late orders and service risk based on execution drift, queue formation, and downstream capacity constraints.

- Anomaly detection across inventory and process data, surfacing shrinkage, mis-scans, tracking errors, and abnormal operational behaviour.

- Quality and accuracy verification at execution speed using computer vision to detect mislabelling, incorrect picks, or product defects during picking and packing.

- Proactive equipment and safety risk signals derived from telemetry and video analytics, enabling intervention before failures or incidents occur.

What AI detects is not a single failure, but the conditions that make failure increasingly likely. A modest slowdown in one picking zone, paired with rising queue depth and reduced conveyor throughput, may be operationally acceptable on its own. In combination, it often precedes missed cut-offs or cascading congestion. The use of AI in warehouse management surfaces these compound risk patterns before they are visible in dashboards or reports.

N-iX has also implemented ML systems that surface early risk signals in high-volume digital environments, such as churn prediction on large ecommerce platforms. While the domain differs, the underlying approach, detecting correlated deviations before outcomes materialize, directly parallels how AI identifies emerging operational risks, late orders, or congestion patterns in warehouse execution.

Key challenges of AI for warehouse management implementation and how to overcome them

Most warehouse AI initiatives fail for reasons that have little to do with model quality. In operational environments, AI succeeds or fails based on whether it improves decision behaviour under pressure. Teams do not evaluate AI solely on accuracy metrics. They assess it through decision-quality signals embedded in daily execution, such as:

- Sustained reduction in manual overrides during live shifts;

- Fewer late or deferred order releases during peak windows;

- Tighter variance in pick-path congestion across zones;

- Lower frequency of reactive labor reallocation.

These signals surface days or weeks before financial KPIs move. When they remain unchanged, the AI has no significant influence on operations, regardless of its technical sophistication.

One structural failure pattern is decision ambiguity. AI is often deployed without clearly defining which decisions it owns, which it informs, and which remain human-controlled. As a result, recommendations are ignored, overridden, or inconsistently applied. Successful programmes isolate a single, high-leverage decision domain, such as release timing, high-velocity SKU placement, or shift-level labor allocation, and improve it end-to-end before expanding scope.

Another frequent issue is premature automation. Moving directly from experimentation to automated execution introduces risk before trust has been established. In effective deployments, AI is first run in advisory or shadow mode. Supervisors compare recommendations with their own judgment, observe where AI consistently outperforms intuition, and identify where human discretion remains essential.

Warehouses typically see the strongest results from AI after execution data stabilises, manual overrides decline, and core WMS events are consistently captured. Where these conditions are missing, AI exposes erratic behavior.

Greater AI adoption does not automatically produce better warehouse performance. In several environments, implementing AI too deeply into execution layers has increased instability rather than reduced it. The most impactful and durable returns typically come from strengthening planning, release, and coordination decisions first.

Measurement misalignment also undermines adoption. Many teams track model performance instead of operational impact. Forecast accuracy, confidence scores, or optimisation outputs do not explain whether congestion was avoided or service risk reduced. Mature teams measure AI against execution outcomes and behavioural signals, treating override frequency, intervention timing, and response latency as leading indicators of success.

This distinction becomes clear in real warehouse operations. In an industrial logistics environment, N-iX applied Machine Learning to improve operational efficiency under real execution constraints. The engagement focused on analyzing live operational data, identifying inefficiencies not visible in standard reporting, and embedding ML models into decision-support workflows. The project reinforced a recurring pattern: AI delivers impact when it is tied to concrete operational decisions and validated under production conditions.

Here, implementation experience matters. At N-iX, warehouse AI initiatives are approached as decision-system advancements. Our teams work with enterprise logistics and supply chain environments to integrate AI directly into WMS, labor management, and execution layers, ensuring recommendations arrive at the moment decisions are made.

In a retail environment is often characterized by volatile demand and short planning cycles. N-iX supported a leading retail organization by applying AI to rapid prototyping and scenario evaluation. Our efforts focused on reducing the time between signal detection and operational response, allowing teams to validate assumptions early and adjust execution logic before constraints hardened.

How to implement AI in warehouse management

Implementing AI in warehouse management is not fundamentally different from introducing any other mission-critical operational technology. The mechanics are familiar: clarify the business problem, integrate with existing systems, test under real conditions, and scale only after impact is proven. What changes with AI is that mistakes become expensive when decisions shift from human judgment to machine-supported execution.

In practice, successful implementations follow a predictable pattern. Enterprises begin by stabilizing data flows from core systems such as WMS, labor management, and automation platforms. From there, AI is applied to a narrowly defined decision area—often in advisory mode first, so teams can validate behaviour under real operational pressure before automation is expanded. Only after decision quality improves consistently do organizations scale AI across additional processes.

The most important factor is not the model itself, but how AI is embedded into day-to-day operations. AI must align with existing workflows, respect execution constraints, and deliver recommendations at the exact moment decisions are made. Without that alignment, even technically strong solutions fail to influence outcomes.

According to McKinsey’s State of AI report, organisations that integrate AI into core operational workflows, rather than running it as a standalone analytical layer, are far more likely to achieve sustained business impact.

This is where experience matters. At N-iX, AI implementation is built on delivery scale and operational experience. Over more than 23 years in the market, we have delivered 60 data science and AI projects across complex enterprise environments.

Our teams include more than 200 data, AI, and machine learning engineers working with warehouse and logistics operations. In warehouse and logistics environments, AI typically combines ML and predictive analytics for demand, labor, and release decisions; computer vision for quality, safety, and exception detection; and data science to reliably integrate these models into WMS and execution workflows. If you are assessing where AI can realistically improve warehouse performance under real operational constraints, we can help evaluate and implement the right use cases.

FAQ

What problems does AI actually solve in warehouse management?

AI in warehouse management improves decision quality in high-variability contexts, such as inventory positioning, order release timing, labor allocation, and congestion control. It supports decisions that depend on incomplete or rapidly changing information. The impact is visible in fewer overrides, more stable throughput, and better service reliability under peak conditions.

How long does it take to see results from integrating AI in warehouse operations?

Initial operational signals often appear within weeks, especially in decision areas like release timing or demand sensing. Measurable performance improvements typically follow once AI is integrated into live workflows and decision ownership is clear. The timeline depends less on model complexity and more on data readiness and system integration.

Does AI require replacing an existing WMS or warehouse systems?

In most enterprise environments, AI is implemented alongside existing WMS, labor management, and execution systems. The focus is on integrating AI into decision points instead of replacing core platforms. Replacing systems is rarely necessary and often introduces avoidable risk.

Have a question?

Speak to an expert