Is it possible to maintain perfect consistency when every product rolling off the line is slightly different? Turns out, the answer is yes-with computer vision. Traditional inspection methods have struggled with this problem for decades: human inspectors face fatigue and subjectivity, while rule-based systems operate quickly but fail when encountering unexpected defects.

Computer vision shifts this balance. Instead of following pre-set rules, AI-driven systems learn from real-world variability, recognize anomalies in real time, and provide data that links defects back to their root causes. Quality inspection can become a continuous feedback loop that strengthens compliance, lowers risk exposure, and improves efficiency. Let's look at how computer vision quality inspection can be applied today to maintain control before those gaps become costly setbacks.

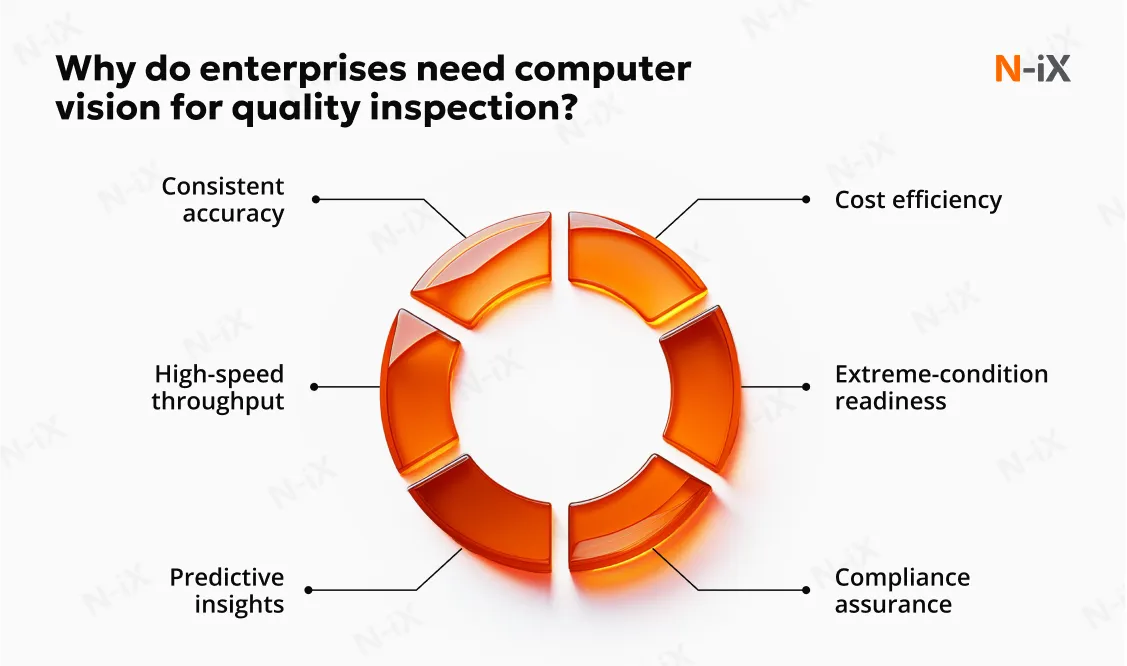

Why do enterprises need computer vision for quality inspection?

The cracks in conventional approaches like manual checks and traditional rule-based systems begin to show. Computer vision, strengthened by Artificial Intelligence and Machine Learning, directly overcomes the constraints of human and legacy systems. The question then becomes: why do enterprises need it now?

To overcome the limits of human inspection

Fatigue, distraction, and subjectivity all reduce reliability over time. AI-powered vision inspection systems can achieve 97%-99% detection accuracy, compared to manual inspection, which misses 20-30% of defects. And when the cost of a missed flaw can be a recall, a regulatory fine, or reputational damage, such error rates are unsustainable. CV delivers the consistency and objectivity that human inspection cannot sustain at scale.

Compare machine vision and computer vision—choose the right technology for your needs!

Success!

To keep pace with production speed

Manufacturing output continues to accelerate. That raises the question: how can inspection keep up? CV systems process hundreds of items per minute in real time, maintaining stable accuracy. Computer vision quality inspection manufacturing eliminates quality control bottlenecks and allows enterprises to expand production capacity.

To enable predictive and continuous improvement

Traditional inspection ends with a binary outcome: pass or fail. Computer vision produces continuous streams of quality data. When analyzed over time, these data reveal defect trends, equipment performance issues, and systemic weaknesses that would otherwise remain invisible. Enterprises can use these insights to address risks before they materialize and embed continuous improvement into operations.

To strengthen financial resilience and profitability

The financial implications of inspection reach far beyond the quality department. Scrap, rework, warranty claims, and product recalls directly affect margins. Computer vision reduces these costs by detecting defects earlier, with greater accuracy, and at higher volumes. Over time, this shift lowers the quality cost while accelerating time-to-market.

To extend inspection to challenging environments

Not all inspection work is safe or even possible for people. High temperatures, sterile environments, or exposure to hazardous materials limit human involvement. CV systems, equipped with tailored optics, lighting, and AI-driven models, are built to address these scenarios.

To meet regulatory and market demands

Customers and regulators now require traceable, auditable evidence that inspection has been carried out to precise standards. Computer vision quality inspection automatically generates structured records (images, classifications, measurements, etc) linked to every unit inspected. Quality control vision systems provide valuable insight into recurring defect sources.

How computer vision inspection works

A computer vision inspection system operates through a structured pipeline that combines hardware, software, and AI models to capture, process, and evaluate visual data in real time.

Let's look at the computer vision quality inspection process.

Step 1: Building a reliable hardware foundation

The process starts with image capture. Industrial cameras are chosen according to the product and inspection requirements: RGB cameras for color-sensitive analysis, area-scan cameras for stationary items, and line-scan cameras for products moving at high speed. When a single perspective is insufficient, multiple cameras are combined to create a 360-degree view. High-resolution sensors are critical here, since they allow detection of even the most minor irregularities.

Lighting is the second pillar of image acquisition. Without controlled illumination, even advanced cameras cannot deliver reliable inputs. Purpose-built lighting systems maintain consistent brightness, suppress glare on reflective or transparent materials, and maximize contrast so that features and potential defects stand out. Techniques such as structured or binary active lighting are often deployed to reveal invisible surface variations under standard conditions.

Finally, part handling ensures that the product is aligned correctly. Conveyors, robotic fixtures, or mechanical mounts stabilize items even under high throughput, compensating for vibration, random positioning, or sudden changes in line speed. Without this stability, image quality and inspection accuracy would inevitably suffer.

Step 2: Preparing images for analysis

Once captured, the raw images are not yet ready for analysis. Preprocessing transforms them into standardized inputs for computer vision algorithms. This step includes noise reduction to eliminate irrelevant visual data, contrast enhancement to make surface defects more prominent, and edge detection to delineate product boundaries accurately.

During this step, most images are captured in the RGB format; other color models, such as HSV (Hue, Saturation, Value) or YIQ (Luminance, In-phase, Quadrature), are often used in computer vision to separate brightness and color information. This separation allows the system to extract features more effectively under varying lighting conditions or when inspecting materials where subtle color differences indicate defects.

Step 3: Feature extraction and recognition

At this stage, algorithms begin to interpret the visual data. The system extracts relevant features such as shapes, textures, colors, or dimensions, which are the basis for defect identification. Techniques like Scale-Invariant Feature Transform (SIFT) identify stable feature points that remain consistent even if the product is rotated, scaled, or positioned differently from the reference orientation.

Defect detection then draws on different approaches, depending on the complexity of the task:

- Deep Learning models: Convolutional Neural Networks (CNNs) are trained on large datasets of labeled product images. These models learn to recognize obvious and subtle defect patterns, adapting to new defect types without manually reprogramming.

- Traditional comparison metrics: Structural Similarity Index Measure (SSIM), Mean Squared Error (MSE), and Peak Signal-to-Noise Ratio (PSNR) quantify differences between the inspected image and a defect-free reference.

- Template matching and rule-based systems: The system compares an image to a "golden" template for simpler tasks. Any deviations, such as misaligned labels or missing features, are flagged as defects. While less flexible, this approach is highly reliable when quality criteria are clearly defined and do not change frequently.

Step 4: Classification and decision-making

The final step is to classify the product and transmit the decision to the production system. Extracted features and anomalies are evaluated against predefined tolerances or classification rules. Advanced classifiers, such as Support Vector Data Description (SVDD) or Quadratic Distance Classifiers, may handle complex decision boundaries.

Once a decision is reached, pass, fail, or category-specific, it is transmitted to production equipment through programmable logic controllers. This direct connection enables immediate responses: an ejector can remove defective products, or a robotic arm can divert them for rework. This way, inspection becomes a monitoring step and an integrated part of production control.

Key computer vision functionalities in industrial inspection

Modern computer vision systems in industrial inspection provide a set of core functionalities that address the essential requirements of quality assurance. But how exactly do these systems achieve that level of reliability? The following outlines the main functional areas and how they operate in practice.

Automated detection of defects and flaws

In inspection, the most critical function of computer vision is automatically identifying and classifying physical imperfections precisely.

Surface and structural defect detection

High-resolution optics combined with specialized algorithms allow CV systems to analyze fine surface details. They detect scratches, cracks, dents, discolorations, holes, or irregular textures: issues that may be subtle to the human eye but critical for product integrity. For example, in electronics, these systems verify solder joints and the alignment of components on high-density circuit boards. They identify micro-defects on surfaces that could compromise structural performance in metal processing. Even transparent defects larger than 0.8 mm are reliably detected. Importantly, detection is not limited to "yes or no" outputs. Defects are also classified by size, shape, and geometry (such as punctual or linear) and precisely located for corrective action.

Beyond simple detection, modern computer vision quality inspection platforms support defect analysis and localization, enabling the identification of the type and size of a flaw and pinpointing its precise coordinates on the product.

During a hardware repair project, N-iX built a CV system that scans laptop motherboards across over 2,000 models to identify defects and propose likely root causes. They also integrated thermal imaging to highlight overheated components, reducing average troubleshooting time from 30 minutes to under 10. This example illustrates how CV quality inspection can combine multiple modalities and deliver a measurable impact on repair throughput and accuracy.

Anomaly detection and comparison

How can a system decide whether a product conforms to an ideal standard? CV systems rely on quantitative comparisons. Algorithms such as SSIM, MSE, and PSNR evaluate how closely a product matches its reference. At the same time, methods like SIFT verify whether detection is stable even when items are rotated or vary slightly in scale. Template matching and edge detection effectively flag anomalies for production environments with crack, scratch, or misplaced sticker tasks.

Color and material inspection

Inspection extends to appearance and material consistency. CV systems can detect subtle hue, brightness, or concentration variations by converting captured images into alternative color spaces such as HSV or YIQ. Consider beverage manufacturing, where exact liquid levels and precise color intensity directly determine product quality. Similarly, computer vision quality inspection manufacturing evaluates surface finishes and texture uniformity in coatings or plastics, checking that every product aligns with visual standards.

Precision measurement and verification

Another essential contribution of computer vision is advancing quantitative verification with accuracy and repeatability beyond manual methods.

- Dimensional measurement (gauging): Calibrated imaging systems verify geometric parameters such as length, width, height, thickness, and orientation. This functionality extends to specialized gauging tasks, such as verification of coating thickness, measuring concentricity of drilled holes, or assessing flatness of machined surfaces.

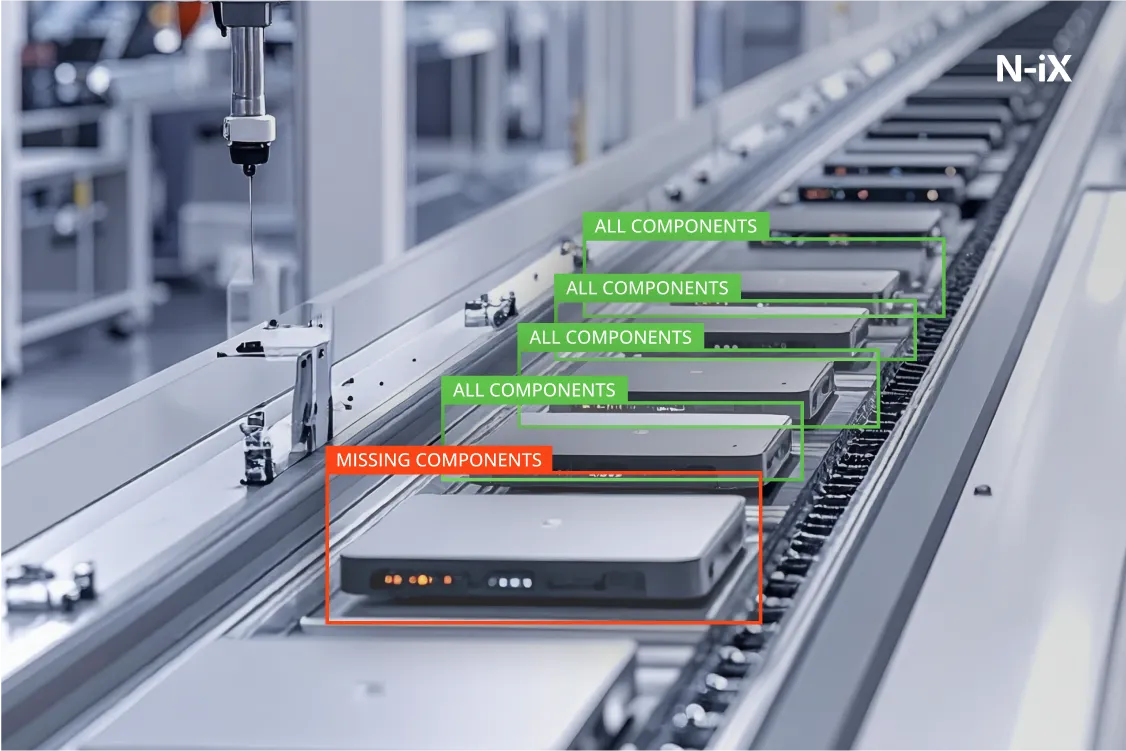

- Assembly and completeness checks: CV systems can confirm that screws, connectors, springs, or caps are present and aligned. The same applies to labels, fasteners, or caps on packaging lines.

- Positioning and alignment: Beyond presence verification, CV systems are also used for high-precision positioning and alignment. CV guides tools in robotics, welding, and cutting operations and verifies their alignment in real time.

- Packaging and label verification: CV systems use OCR and barcode reading to validate printed information, regardless of distortions, angled placement, or minor print damage. Alongside information accuracy, CV inspects seal integrity and confirms that contents are secured, protecting against leaks or contamination.

Advanced functionalities and process integration

Computer vision evolves from a static checkpoint into a fully integrated production element as industrial inspection grows more complex.

- Object detection, recognition, and classification: Beyond detecting defects, CV systems identify attributes such as size, type, or shape, and use this information for sorting, counting, or categorizing items.

- Real-time monitoring: Modern CV platforms do not simply record the issue; they act immediately. Operating at line speed, computer vision in quality control processes hundreds of products per minute and sends instructions to PLCs or robotic systems.

- Data management and traceability: Each inspection generates records (barcode scans, dimensional measurements, defect logs, etc.) that build a traceable history for every product batch. Manufacturers can identify recurring problems by reviewing defect trends, linking them to upstream processes, and implementing targeted improvements.

- Predictive and continuous learning capabilities: With Deep Learning integration, CV systems continuously refine their accuracy by learning from newly captured data. They adapt to evolving product designs and recognize emerging defect types without extensive manual adjustments.

Considerations in adopting computer vision quality inspection

N-iX approaches each implementation as an enterprise transformation initiative rather than a single technology rollout. We focus on aligning the inspection system with product characteristics, production environments, and business objectives. The key considerations can be grouped into four areas:

1. Imaging and hardware design

Reliable inspection begins with reliable image acquisition. The quality of images dictates the accuracy of all downstream analytics. At N-iX, we design imaging setups tailored to the product and environment rather than relying on off-the-shelf configurations.

- Custom optics and lighting to address reflective, transparent, or irregular surfaces.

- Camera and sensor selection aligned with defect size and inspection speed, whether a high-resolution area or a high-throughput line scan.

- Stability engineering to ensure consistent positioning of products in high-speed environments.

2. Data and algorithm strategy

The effectiveness of AI inspection depends on the quality of the training data and the models' robustness. We emphasize building data pipelines that allow systems to adapt and improve over time.

- Balanced and representative datasets, often augmented with synthetic images to address the scarcity of defect cases.

- Hybrid models, combining rule-based methods for well-defined tolerances with deep learning for subtle and evolving defect detection.

- Continuous retraining frameworks, ensuring models remain relevant as product designs, materials, or environmental conditions change.

3. System integration and scalability

An inspection solution must be more than accurate-it must integrate seamlessly into enterprise operations. We focus on designing systems that fit into broader manufacturing ecosystems without creating friction.

- Integration with MES, ERP, and PLC systems to automate real-time decision-making and corrective actions.

- Scalable architectures that allow pilots to be expanded across lines, plants, or product categories without re-engineering.

- Deployment accelerators, reducing the time-to-value of inspection systems.

4. Human and organizational enablement

No system succeeds without people. Adoption requires skills, acceptance, and a clear change management plan. We work with manufacturers to ensure technology adoption is paired with workforce readiness.

- Upskilling and enablement programs, equipping engineers and operators to work effectively with AI-driven inspection.

- Assistive framing, positioning computer vision as a complement to human expertise, not a replacement.

- Knowledge capture from experts, transforming tacit know-how into structured data for model training and continuous improvement.

Adopting computer vision for quality inspection is as much about strategy as technology. The systems must see with precision, learn from variability, and integrate seamlessly into production workflows. But even the best-designed models fail without the right data pipelines, robust infrastructure, and organizational readiness. That is why enterprises increasingly look for partners who combine technical depth with the ability to align solutions to business outcomes.

With 23+ years of engineering experience, a team of 200+ AI, ML, and data experts, and 400+ certified specialists across data and cloud platforms, we have guided global enterprises through the shift from manual inspection to AI-driven quality assurance. We bring the scale of 2,400+ specialists and proven delivery on 60+ advanced AI and data science projects, all focused on making computer vision inspection feasible and transformative.

Ready to see how computer vision can strengthen your quality assurance, compliance, and profitability? Talk to us

Have a question?

Speak to an expert